正在加载图片...

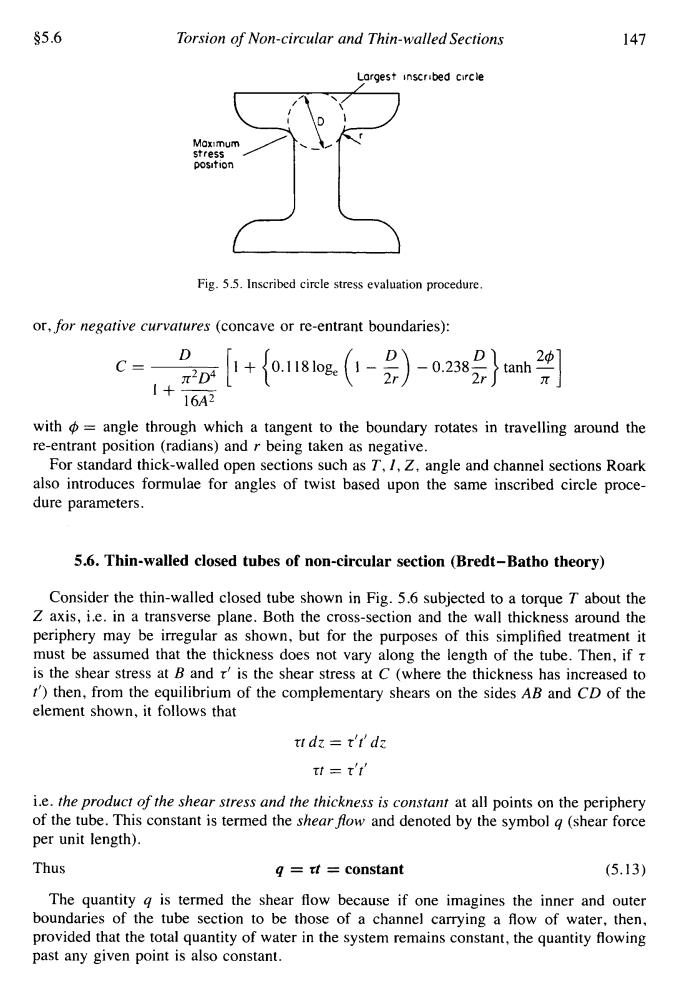

§5.6 Torsion of Non-circular and Thin-walled Sections 147 Largest inscribed circle stress Fig.5.5.Inscribed circle stress evaluation procedure. or,for negative curvatures (concave or re-entrant boundaries): D 2 C=- π2D tanh 1+ 16A2 with =angle through which a tangent to the boundary rotates in travelling around the re-entrant position (radians)and r being taken as negative. For standard thick-walled open sections such as T,1,Z,angle and channel sections Roark also introduces formulae for angles of twist based upon the same inscribed circle proce- dure parameters. 5.6.Thin-walled closed tubes of non-circular section (Bredt-Batho theory) Consider the thin-walled closed tube shown in Fig.5.6 subjected to a torque T about the Z axis,i.e.in a transverse plane.Both the cross-section and the wall thickness around the periphery may be irregular as shown,but for the purposes of this simplified treatment it must be assumed that the thickness does not vary along the length of the tube.Then,if t is the shear stress at B and r'is the shear stress at C (where the thickness has increased to t')then,from the equilibrium of the complementary shears on the sides AB and CD of the element shown,it follows that udz =r't'dz t t'r i.e.the product of the shear stress and the thickness is constant at all points on the periphery of the tube.This constant is termed the shear flow and denoted by the symbol g (shear force per unit length). Thus g=rt constant (5.13) The quantity q is termed the shear flow because if one imagines the inner and outer boundaries of the tube section to be those of a channel carrying a flow of water,then. provided that the total quantity of water in the system remains constant,the quantity flowing past any given point is also constant.$5.6 Torsion of Non-circular and Thin-walled Sections 147 Largest inscribed circle / stress position Fig. 5.5. Inscribed circle stress evaluation procedure. or, for negative curvatures (concave or re-entrant boundaries): D 1 + O.1181oge I - - -0.238- tanhC= n2D4 [ { ( :) z} ?] with 4 = angle through which a tangent to the boundary rotates in travelling around the re-entrant position (radians) and r being taken as negative. For standard thick-walled open sections such as T, I, Z, angle and channel sections Roark also introduces formulae for angles of twist based upon the same inscribed circle procedure parameters. 5.6. Thin-walled closed tubes of non-circular section (Bredt-Batho theory) Consider the thin-walled closed tube shown in Fig. 5.6 subjected to a torque T about the Z axis, i.e. in a transverse plane. Both the cross-section and the wall thickness around the periphery may be irregular as shown, but for the purposes of this simplified treatment it must be assumed that the thickness does not vary along the length of the tube. Then, if r is the shear stress at B and r’ is the shear stress at C (where the thickness has increased to t’) then, from the equilibrium of the complementary shears on the sides AB and CD of the element shown, it follows that rt dz = r‘t’ dz tt = r’t’ i.e. the product of the shear stress and the thickness is constant at all points on the periphery of the tube. This constant is termed the shearjow and denoted by the symbol q (shear force per unit length). Thus q = tt = constant (5.13) The quantity q is termed the shear flow because if one imagines the inner and outer boundaries of the tube section to be those of a channel carrying a flow of water, then, provided that the total quantity of water in the system remains constant, the quantity flowing past any given point is also constant