正在加载图片...

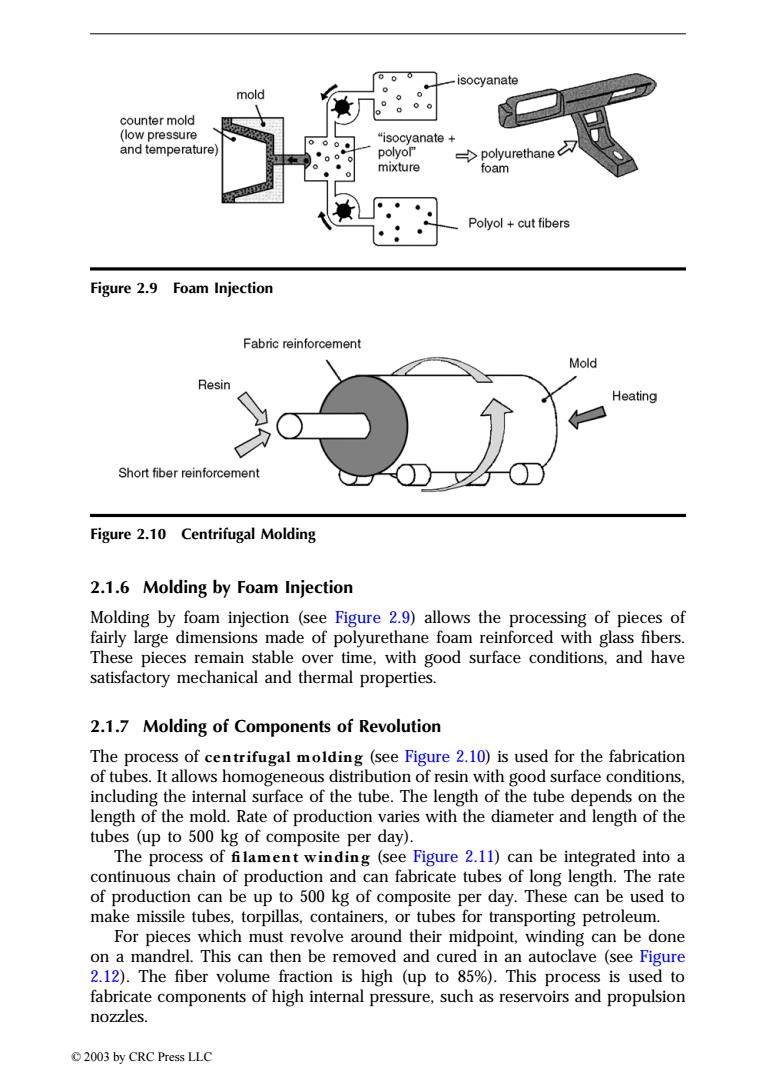

isocyanate mold counter mold (low pressure “isocyanate+ and temperature polyol" >polyurethane mixture foam Polyol cut fibers Figure 2.9 Foam Injection Fabric reinforcement Mold Resin Heating Short fiber reinforcement Figure 2.10 Centrifugal Molding 2.1.6 Molding by Foam Injection Molding by foam injection (see Figure 2.9)allows the processing of pieces of fairly large dimensions made of polyurethane foam reinforced with glass fibers. These pieces remain stable over time,with good surface conditions.and have satisfactory mechanical and thermal properties. 2.1.7 Molding of Components of Revolution The process of centrifugal molding (see Figure 2.10)is used for the fabrication of tubes.It allows homogeneous distribution of resin with good surface conditions. including the internal surface of the tube.The length of the tube depends on the length of the mold.Rate of production varies with the diameter and length of the tubes(up to 500 kg of composite per day). The process of filament winding (see Figure 2.11)can be integrated into a continuous chain of production and can fabricate tubes of long length.The rate of production can be up to 500 kg of composite per day.These can be used to make missile tubes,torpillas,containers,or tubes for transporting petroleum. For pieces which must revolve around their midpoint,winding can be done on a mandrel.This can then be removed and cured in an autoclave (see Figure 2.12).The fiber volume fraction is high (up to 85%).This process is used to fabricate components of high internal pressure,such as reservoirs and propulsion nozzles. 2003 by CRC Press LLC2.1.6 Molding by Foam Injection Molding by foam injection (see Figure 2.9) allows the processing of pieces of fairly large dimensions made of polyurethane foam reinforced with glass fibers. These pieces remain stable over time, with good surface conditions, and have satisfactory mechanical and thermal properties. 2.1.7 Molding of Components of Revolution The process of centrifugal molding (see Figure 2.10) is used for the fabrication of tubes. It allows homogeneous distribution of resin with good surface conditions, including the internal surface of the tube. The length of the tube depends on the length of the mold. Rate of production varies with the diameter and length of the tubes (up to 500 kg of composite per day). The process of filament winding (see Figure 2.11) can be integrated into a continuous chain of production and can fabricate tubes of long length. The rate of production can be up to 500 kg of composite per day. These can be used to make missile tubes, torpillas, containers, or tubes for transporting petroleum. For pieces which must revolve around their midpoint, winding can be done on a mandrel. This can then be removed and cured in an autoclave (see Figure 2.12). The fiber volume fraction is high (up to 85%). This process is used to fabricate components of high internal pressure, such as reservoirs and propulsion nozzles. Figure 2.9 Foam Injection Figure 2.10 Centrifugal Molding TX846_Frame_C02 Page 21 Monday, November 18, 2002 10:40 AM © 2003 by CRC Press LLC