正在加载图片...

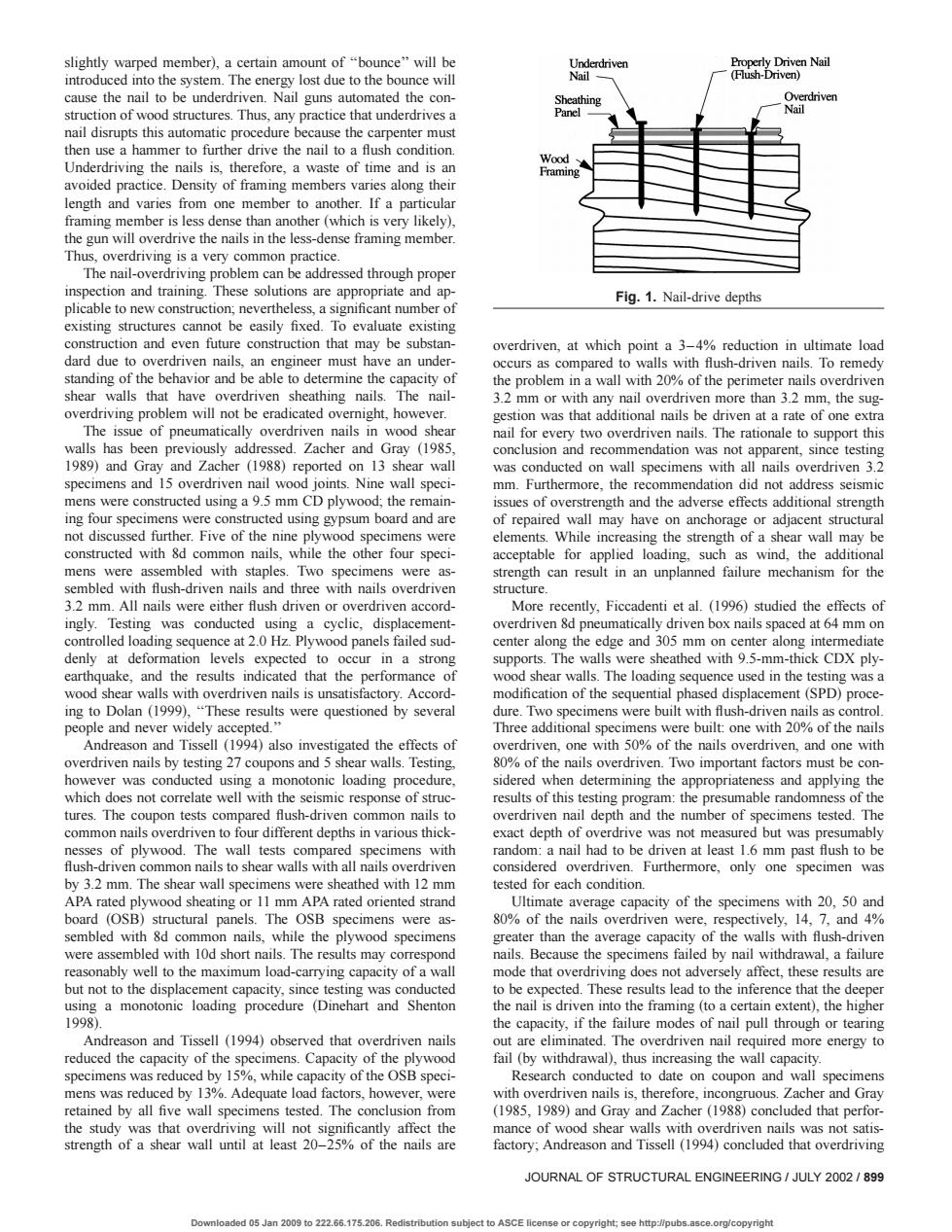

nto the sysm The ery 一Rm struction of ood structures.Thus,any practice that underdrives a Underdriving the nails is,therefore,a waste of time and is an avoided practi s om ssed through ne and training appropriate and ap- Fig.1.Nail-drive depths and even futt construction that na tan overdriven.at which point a 3-4%reduction in ultimate loac fush-driven nail shear have overdriven 32mm or with any nail overdriven more.the su ove dcatedoY .Zache and Gra 198 an (1988 13s was conducted on wall specimens with all verdriven nstructed using a95mm CD plywood,the ren issues of overstrength and the adverse effects additional str rd and ar of repaired wall may have on anchorage or adjaccnt nails while the other four spe acceptable for applied loading. such as wind the additiona me with c as led with flush- strength can result in an unplanned failure mechanism for the 32 verdriven acc More recently,Ficcadenti et al.(1996)studied the effects of ngly ove nven 8d ven box hails space at 64 mm o denly at atior vels xpected to in a strong ports.The walls were sheathed thmm-thickCDX ply perform nce wood shear wal The loading sequn used in th ing to Dolan (1999 h se re were que ens were built peop sell (1994)also with s 5096o 27 coupons ands hov applying th tures The coupn tests compared fush-dr ren common nail overdriven na depthand the umer of tested.The ent dep exact depth dvas not ommon nails to she walls with all ails o verdriver only one specimen was 2 les h of the with 20,50 and board (OSB) 80 of the overdriven were.respectiv 4. and 4% sem tnan th with 10d s The well to the maximum load-carrying capa ity of a wal mode that ove not advers se results an rta th the highe 1998 the capac ity,if the failure modes of nail pull through or tearing sell(1994) ed ity of th the specimens was red ced by 1 while capac arch conc to date on coupon and w n f 1985989 and acher (1 that p ng no ance of ood she strength unt ctory.Andreason an JOURNAL OF STRUCTURAL ENGINEERING/JULY 2002/89 20slightly warped member!, a certain amount of ‘‘bounce’’ will be introduced into the system. The energy lost due to the bounce will cause the nail to be underdriven. Nail guns automated the construction of wood structures. Thus, any practice that underdrives a nail disrupts this automatic procedure because the carpenter must then use a hammer to further drive the nail to a flush condition. Underdriving the nails is, therefore, a waste of time and is an avoided practice. Density of framing members varies along their length and varies from one member to another. If a particular framing member is less dense than another ~which is very likely!, the gun will overdrive the nails in the less-dense framing member. Thus, overdriving is a very common practice. The nail-overdriving problem can be addressed through proper inspection and training. These solutions are appropriate and applicable to new construction; nevertheless, a significant number of existing structures cannot be easily fixed. To evaluate existing construction and even future construction that may be substandard due to overdriven nails, an engineer must have an understanding of the behavior and be able to determine the capacity of shear walls that have overdriven sheathing nails. The nailoverdriving problem will not be eradicated overnight, however. The issue of pneumatically overdriven nails in wood shear walls has been previously addressed. Zacher and Gray ~1985, 1989! and Gray and Zacher ~1988! reported on 13 shear wall specimens and 15 overdriven nail wood joints. Nine wall specimens were constructed using a 9.5 mm CD plywood; the remaining four specimens were constructed using gypsum board and are not discussed further. Five of the nine plywood specimens were constructed with 8d common nails, while the other four specimens were assembled with staples. Two specimens were assembled with flush-driven nails and three with nails overdriven 3.2 mm. All nails were either flush driven or overdriven accordingly. Testing was conducted using a cyclic, displacementcontrolled loading sequence at 2.0 Hz. Plywood panels failed suddenly at deformation levels expected to occur in a strong earthquake, and the results indicated that the performance of wood shear walls with overdriven nails is unsatisfactory. According to Dolan ~1999!, ‘‘These results were questioned by several people and never widely accepted.’’ Andreason and Tissell ~1994! also investigated the effects of overdriven nails by testing 27 coupons and 5 shear walls. Testing, however was conducted using a monotonic loading procedure, which does not correlate well with the seismic response of structures. The coupon tests compared flush-driven common nails to common nails overdriven to four different depths in various thicknesses of plywood. The wall tests compared specimens with flush-driven common nails to shear walls with all nails overdriven by 3.2 mm. The shear wall specimens were sheathed with 12 mm APA rated plywood sheating or 11 mm APA rated oriented strand board ~OSB! structural panels. The OSB specimens were assembled with 8d common nails, while the plywood specimens were assembled with 10d short nails. The results may correspond reasonably well to the maximum load-carrying capacity of a wall but not to the displacement capacity, since testing was conducted using a monotonic loading procedure ~Dinehart and Shenton 1998!. Andreason and Tissell ~1994! observed that overdriven nails reduced the capacity of the specimens. Capacity of the plywood specimens was reduced by 15%, while capacity of the OSB specimens was reduced by 13%. Adequate load factors, however, were retained by all five wall specimens tested. The conclusion from the study was that overdriving will not significantly affect the strength of a shear wall until at least 20–25% of the nails are overdriven, at which point a 3–4% reduction in ultimate load occurs as compared to walls with flush-driven nails. To remedy the problem in a wall with 20% of the perimeter nails overdriven 3.2 mm or with any nail overdriven more than 3.2 mm, the suggestion was that additional nails be driven at a rate of one extra nail for every two overdriven nails. The rationale to support this conclusion and recommendation was not apparent, since testing was conducted on wall specimens with all nails overdriven 3.2 mm. Furthermore, the recommendation did not address seismic issues of overstrength and the adverse effects additional strength of repaired wall may have on anchorage or adjacent structural elements. While increasing the strength of a shear wall may be acceptable for applied loading, such as wind, the additional strength can result in an unplanned failure mechanism for the structure. More recently, Ficcadenti et al. ~1996! studied the effects of overdriven 8d pneumatically driven box nails spaced at 64 mm on center along the edge and 305 mm on center along intermediate supports. The walls were sheathed with 9.5-mm-thick CDX plywood shear walls. The loading sequence used in the testing was a modification of the sequential phased displacement ~SPD! procedure. Two specimens were built with flush-driven nails as control. Three additional specimens were built: one with 20% of the nails overdriven, one with 50% of the nails overdriven, and one with 80% of the nails overdriven. Two important factors must be considered when determining the appropriateness and applying the results of this testing program: the presumable randomness of the overdriven nail depth and the number of specimens tested. The exact depth of overdrive was not measured but was presumably random: a nail had to be driven at least 1.6 mm past flush to be considered overdriven. Furthermore, only one specimen was tested for each condition. Ultimate average capacity of the specimens with 20, 50 and 80% of the nails overdriven were, respectively, 14, 7, and 4% greater than the average capacity of the walls with flush-driven nails. Because the specimens failed by nail withdrawal, a failure mode that overdriving does not adversely affect, these results are to be expected. These results lead to the inference that the deeper the nail is driven into the framing ~to a certain extent!, the higher the capacity, if the failure modes of nail pull through or tearing out are eliminated. The overdriven nail required more energy to fail ~by withdrawal!, thus increasing the wall capacity. Research conducted to date on coupon and wall specimens with overdriven nails is, therefore, incongruous. Zacher and Gray ~1985, 1989! and Gray and Zacher ~1988! concluded that performance of wood shear walls with overdriven nails was not satisfactory; Andreason and Tissell ~1994! concluded that overdriving Fig. 1. Nail-drive depths JOURNAL OF STRUCTURAL ENGINEERING / JULY 2002 / 899 Downloaded 05 Jan 2009 to 222.66.175.206. Redistribution subject to ASCE license or copyright; see http://pubs.asce.org/copyright