正在加载图片...

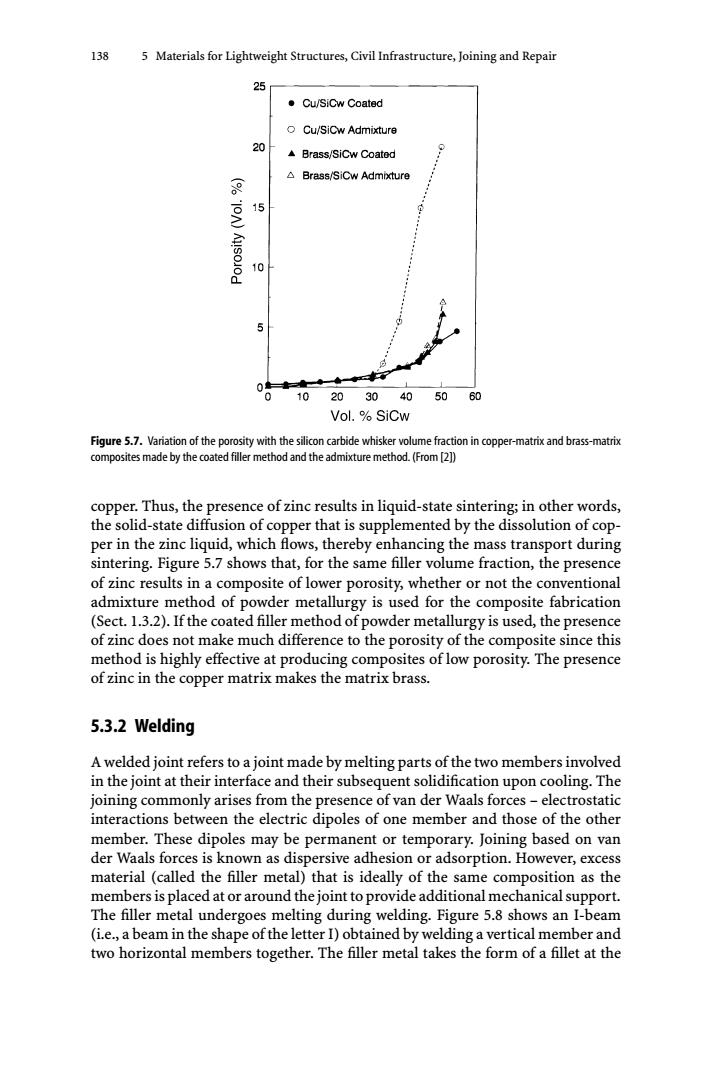

138 5 Materials for Lightweight Structures,Civil Infrastructure,Joining and Repair 25 ●Cu/SiCw Coated Cu/SiCw Admixture 20 ▲Brass/SiCw Coated △Brass/SiCw Admixture IOA) 15 10上 0 102030405060 Vol.SiCw Figure 5.7.Variation of the porosity with the silicon carbide whisker volume fraction in copper-matrix and brass-matrix composites made by the coated filler method and the admixture method.(From[2]) copper.Thus,the presence of zinc results in liquid-state sintering;in other words, the solid-state diffusion of copper that is supplemented by the dissolution of cop- per in the zinc liquid,which flows,thereby enhancing the mass transport during sintering.Figure 5.7 shows that,for the same filler volume fraction,the presence of zinc results in a composite of lower porosity,whether or not the conventional admixture method of powder metallurgy is used for the composite fabrication (Sect.1.3.2).If the coated filler method of powder metallurgy is used,the presence of zinc does not make much difference to the porosity of the composite since this method is highly effective at producing composites of low porosity.The presence of zinc in the copper matrix makes the matrix brass. 5.3.2 Welding A welded joint refers to a joint made by melting parts of the two members involved in the joint at their interface and their subsequent solidification upon cooling.The joining commonly arises from the presence of van der Waals forces-electrostatic interactions between the electric dipoles of one member and those of the other member.These dipoles may be permanent or temporary.Joining based on van der Waals forces is known as dispersive adhesion or adsorption.However,excess material (called the filler metal)that is ideally of the same composition as the members is placed at or around the joint to provide additional mechanical support. The filler metal undergoes melting during welding.Figure 5.8 shows an I-beam (i.e.,a beam in the shape of the letter I)obtained by welding a vertical member and two horizontal members together.The filler metal takes the form of a fillet at the138 5 Materials for Lightweight Structures, Civil Infrastructure, Joining and Repair Figure 5.7. Variation of the porosity with the silicon carbide whisker volume fraction in copper-matrix and brass-matrix composites made by the coated filler method and the admixture method. (From [2]) copper. Thus, the presence of zinc results in liquid-state sintering; in other words, the solid-state diffusion of copper that is supplemented by the dissolution of copper in the zinc liquid, which flows, thereby enhancing the mass transport during sintering. Figure 5.7 shows that, for the same filler volume fraction, the presence of zinc results in a composite of lower porosity, whether or not the conventional admixture method of powder metallurgy is used for the composite fabrication (Sect. 1.3.2). If the coated filler method of powder metallurgy is used, the presence of zinc does not make much difference to the porosity of the composite since this method is highly effective at producing composites of low porosity. The presence of zinc in the copper matrix makes the matrix brass. 5.3.2 Welding A welded joint refers to a joint made by melting parts of the two members involved in the joint at their interface and their subsequent solidification upon cooling. The joining commonly arises from the presence of van der Waals forces – electrostatic interactions between the electric dipoles of one member and those of the other member. These dipoles may be permanent or temporary. Joining based on van der Waals forces is known as dispersive adhesion or adsorption. However, excess material (called the filler metal) that is ideally of the same composition as the members is placed at or around the joint to provide additional mechanical support. The filler metal undergoes melting during welding. Figure 5.8 shows an I-beam (i.e., a beam in the shape of the letter I) obtained by welding a vertical member and two horizontal members together. The filler metal takes the form of a fillet at the