正在加载图片...

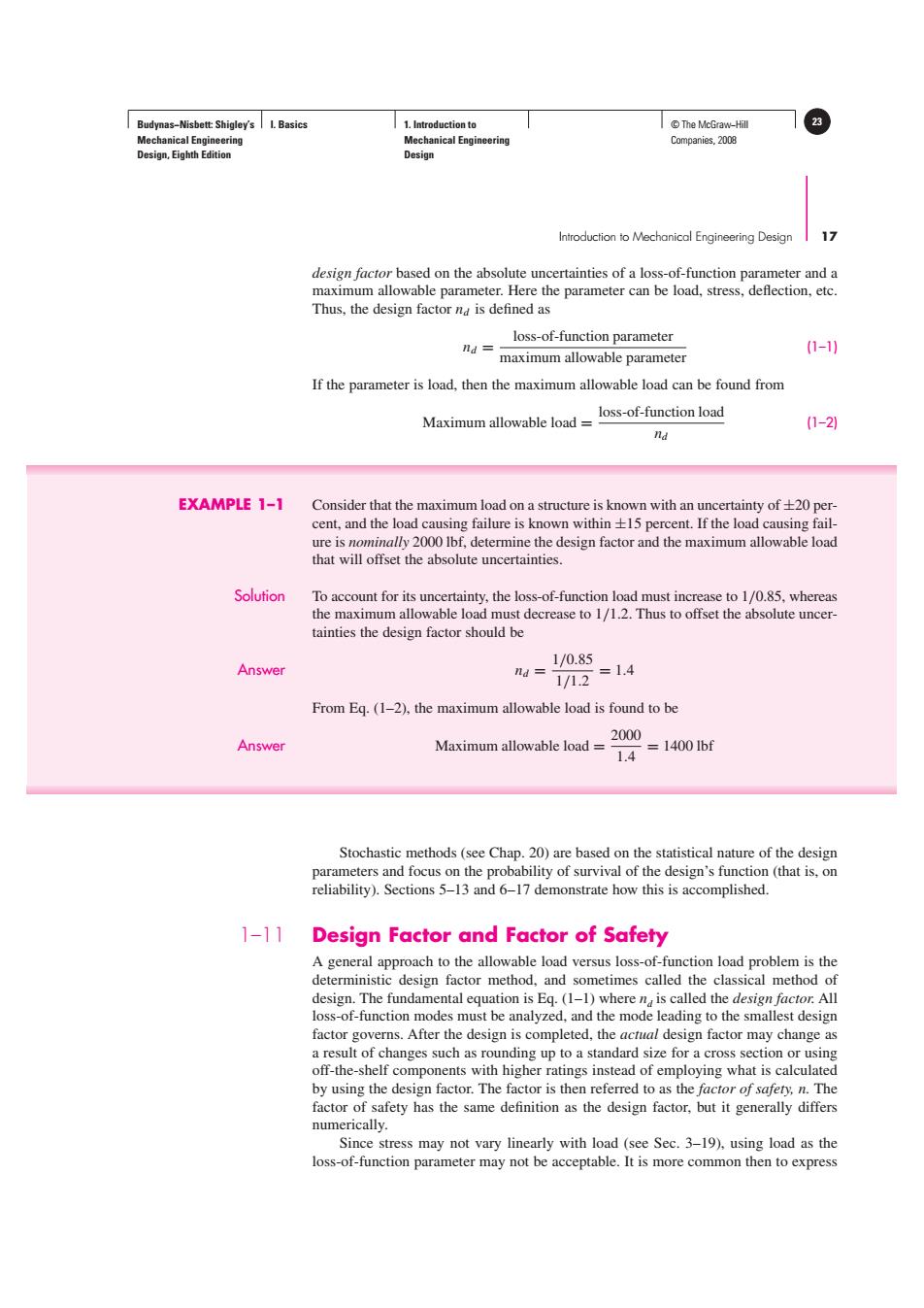

Budynas-Nisbett:Shigley's I.Basics 1.Introduction to ©The McGraw-Hil Mechanical Engineering Mechanical Engineering Companies,2008 Design,Eighth Edition Design Introduction to Mechanical Engineering Design 1> design factor based on the absolute uncertainties of a loss-of-function parameter and a maximum allowable parameter.Here the parameter can be load,stress,deflection,etc. Thus,the design factor nd is defined as loss-of-function parameter nd= (1-1) maximum allowable parameter If the parameter is load,then the maximum allowable load can be found from loss-of-function load Maximum allowable load (1-2) nd EXAMPLE 1-1 Consider that the maximum load on a structure is known with an uncertainty of+20 per- cent,and the load causing failure is known within 15 percent.If the load causing fail- ure is nominally 2000 Ibf,determine the design factor and the maximum allowable load that will offset the absolute uncertainties. Solution To account for its uncertainty,the loss-of-function load must increase to 1/0.85,whereas the maximum allowable load must decrease to 1/1.2.Thus to offset the absolute uncer- tainties the design factor should be Answer 1/0.85 nd 1/1.2 =1.4 From Eq.(1-2),the maximum allowable load is found to be 2000 Answer Maximum allowable load =14001bf 1.4 Stochastic methods(see Chap.20)are based on the statistical nature of the design parameters and focus on the probability of survival of the design's function (that is,on reliability).Sections 5-13 and 6-17 demonstrate how this is accomplished. 1-11 Design Factor and Factor of Safety A general approach to the allowable load versus loss-of-function load problem is the deterministic design factor method,and sometimes called the classical method of design.The fundamental equation is Eq.(1-1)where n is called the design factor.All loss-of-function modes must be analyzed,and the mode leading to the smallest design factor governs.After the design is completed,the actual design factor may change as a result of changes such as rounding up to a standard size for a cross section or using off-the-shelf components with higher ratings instead of employing what is calculated by using the design factor.The factor is then referred to as the factor of safery,n.The factor of safety has the same definition as the design factor,but it generally differs numerically. Since stress may not vary linearly with load (see Sec.3-19),using load as the loss-of-function parameter may not be acceptable.It is more common then to expressBudynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition I. Basics 1. Introduction to Mechanical Engineering Design © The McGraw−Hill 23 Companies, 2008 Introduction to Mechanical Engineering Design 17 design factor based on the absolute uncertainties of a loss-of-function parameter and a maximum allowable parameter. Here the parameter can be load, stress, deflection, etc. Thus, the design factor nd is defined as nd = loss-of-function parameter maximum allowable parameter (1–1) If the parameter is load, then the maximum allowable load can be found from Maximum allowable load = loss-of-function load nd (1–2) EXAMPLE 1–1 Consider that the maximum load on a structure is known with an uncertainty of ±20 percent, and the load causing failure is known within ±15 percent. If the load causing failure is nominally 2000 lbf, determine the design factor and the maximum allowable load that will offset the absolute uncertainties. Solution To account for its uncertainty, the loss-of-function load must increase to 1/0.85, whereas the maximum allowable load must decrease to 1/1.2. Thus to offset the absolute uncertainties the design factor should be Answer nd = 1/0.85 1/1.2 = 1.4 From Eq. (1–2), the maximum allowable load is found to be Answer Maximum allowable load = 2000 1.4 = 1400 lbf Stochastic methods (see Chap. 20) are based on the statistical nature of the design parameters and focus on the probability of survival of the design’s function (that is, on reliability). Sections 5–13 and 6–17 demonstrate how this is accomplished. 1–11 Design Factor and Factor of Safety A general approach to the allowable load versus loss-of-function load problem is the deterministic design factor method, and sometimes called the classical method of design. The fundamental equation is Eq. (1–1) where nd is called the design factor. All loss-of-function modes must be analyzed, and the mode leading to the smallest design factor governs. After the design is completed, the actual design factor may change as a result of changes such as rounding up to a standard size for a cross section or using off-the-shelf components with higher ratings instead of employing what is calculated by using the design factor. The factor is then referred to as the factor of safety, n. The factor of safety has the same definition as the design factor, but it generally differs numerically. Since stress may not vary linearly with load (see Sec. 3–19), using load as the loss-of-function parameter may not be acceptable. It is more common then to express