正在加载图片...

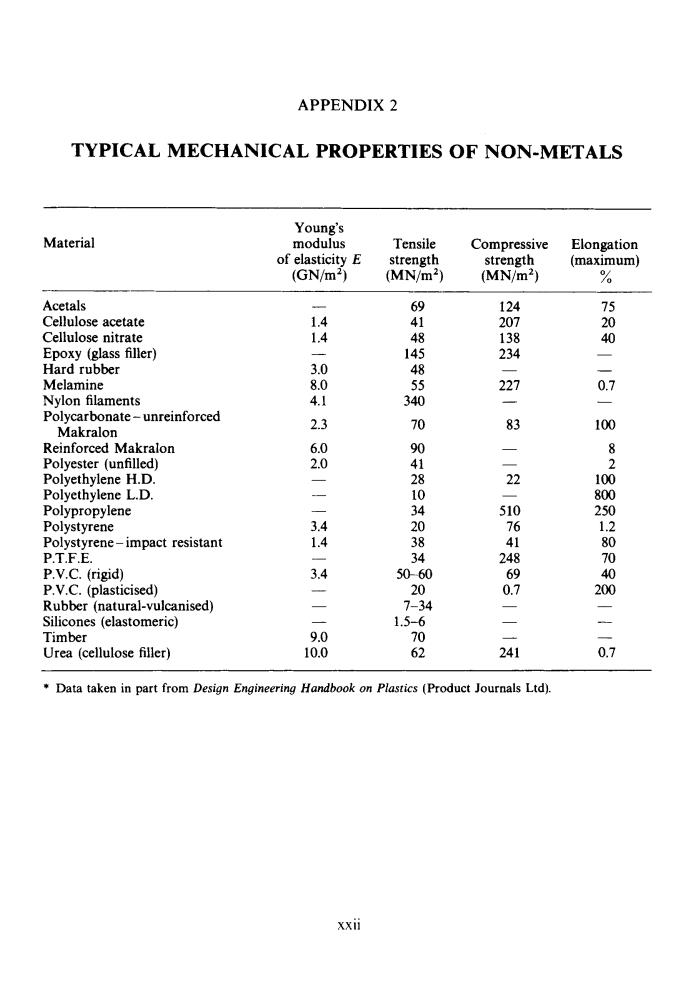

APPENDIX 2 TYPICAL MECHANICAL PROPERTIES OF NON-METALS Young's Material modulus Tensile Compressive Elongation of elasticity E strength strength (maximum) (GN/m2) (MN/m2) (MN/m2) % Acetals 69 124 75 Cellulose acetate 1.4 41 207 20 Cellulose nitrate 48 138 40 Epoxy (glass filler) Hard rubber 30 145 234 Melamine 8 5 227 0.7 Nylon filaments 4.1 34 Polycarbonate-unreinforced Makralon 2.3 70 83 100 Reinforced Makralon 6.0 90 二 Polyester (unfilled) 2.0 45810 2 Polyethylene H.D. 22 100 Polyethylene L.D. 800 Polypropylene 510 250 Polystyrene 3.4 2 76 1.2 Polystyrene-impact resistant 1.4 41 80 P.T.F.E. 34 248 70 P.V.C.(rigid) 34 50-60 69 40 P.V.C.(plasticised) 20 0.7 200 Rubber(natural-vulcanised) 7-34 Silicones (elastomeric) 1.5-6 二 Timber 9.0 70 Urea (cellulose filler) 10.0 2 241 0.7 Data taken in part from Design Engineering Handbook on Plastics(Product Journals Ltd). xxiiAPPENDIX 2 TYPICAL MECHANICAL PROPERTIES OF NON-METALS Material Young’s modulus Tensile Compressive Elongation of elasticity E strength strength (maximum) (GN/mz) (MN/mz) (MN/mZ) % Acetals Cellulose acetate Cellulose nitrate Epoxy (glass filler) Hard rubber Melamine Nylon filaments Polycarbonate - unreinforced Makralon Reinforced Makralon Polyester (unfilled) Polyethylene H.D. Polyethylene L.D. Polypropylene Polystyrene Polystyrene - impact resistant P.T.F.E. P.V.C. (rigid) P.V.C. (plasticised) Rubber (natural-vulcanised) Silicones (elastomeric) Timber Urea (cellulose filler) - 1.4 1.4 3.0 8.0 4.1 2.3 6.0 2.0 - - 3.4 1.4 3.4 - 9.0 10.0 69 41 48 145 48 55 340 70 90 41 28 10 34 20 38 34 50-60 20 7-34 1.5-6 70 62 1 24 207 138 234 221 - 83 - 22 510 76 41 248 69 0.7 - - 241 75 20 40 - 0.7 100 8 2 100 800 250 1.2 80 70 40 200 - - 0.7 * Data taken in part from Design Engineering Handbook on Plastics (Product Journals Ltd). xxii