正在加载图片...

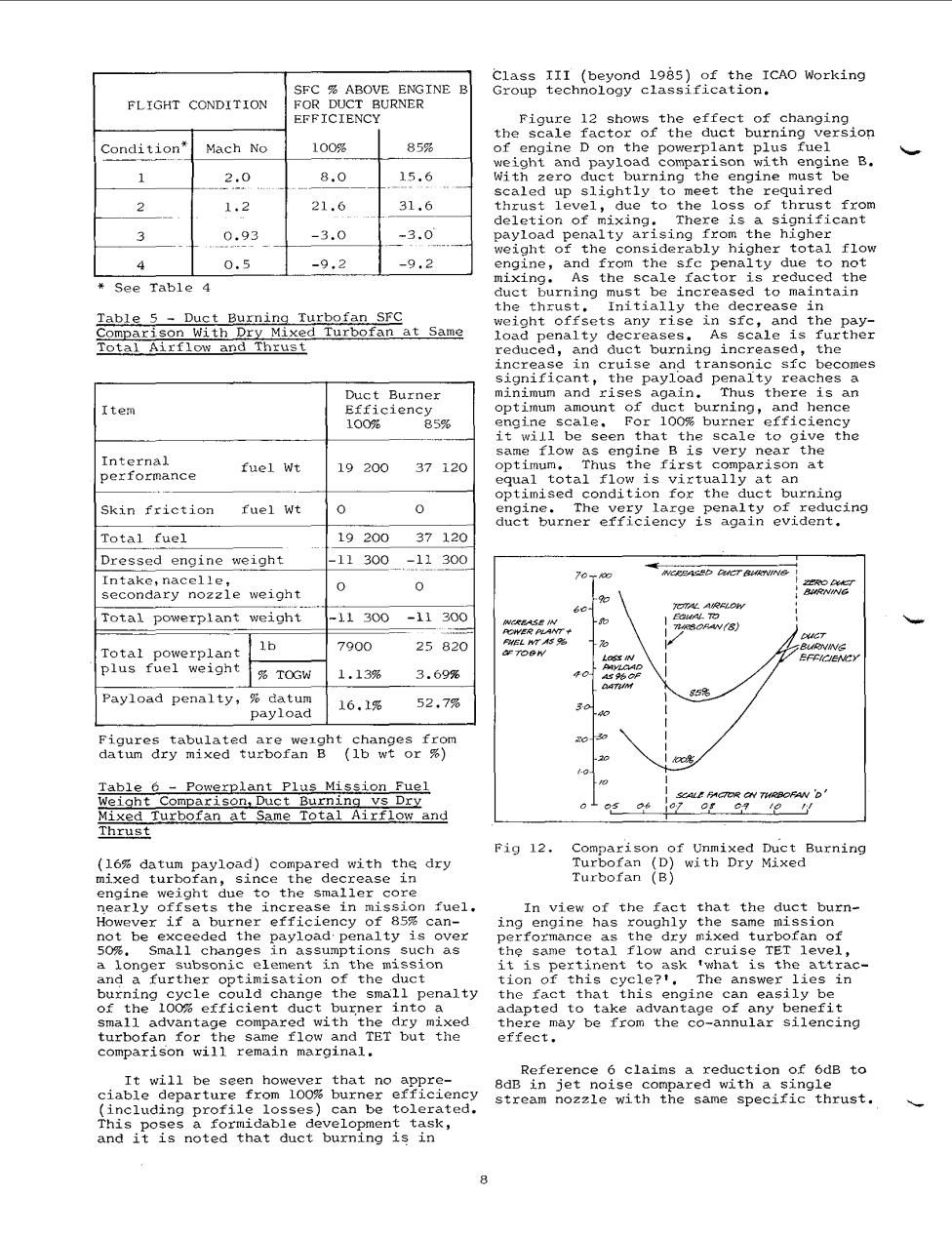

Class III (beyond 1985)of the ICAO Working SFC ABOVE ENGINE B Group technology classification. FLIGHT CONDITION FOR DUCT BURNER EFFICIENCY Figure 12 shows the effect of changing the scale factor of the duct burning version Condition* Mach No 100% 85% of engine D on the powerplant plus fuel weight and payload comparison with engine B. 1 2.0 8.0 15.6 with zero duct burning the engine must be scaled up slightly to meet the required p 1.2 21.6 31.6 thrust level,due to the loss of thrust from deletion of mixing.There is a significant 3 0.93 -3.0 -3.0 payload penalty arising from the higher weight of the considerably higher total flow 4 0.5 -9.2 -9,2 engine,and from the sfc penalty due to not mixing.As the scale factor is reduced the See Table 4 duct burning must be increased to maintain the thrust,Initially the decrease in Table 5 -Duct Burning Turbofan SFC weight offsets any rise in sfc,and the pay- Comparison With Dry Mixed Turbofan at Same load penalty decreases.As scale is further Total Airflow and Thrust reduced,and duct burning increased,the increase in cruise and transonic sfc becomes significant,the payload penalty reaches a Duct Burner minimum and rises again. Thus there is an Item Efficiency optimum amount of duct burning,and hence 100% 85% engine scale,For 100%burner efficiency it will be seen that the scale to give the same flow as engine B is very near the Internal fuel Wt 19200 37120 optimum,Thus the first comparison at performance equal total flow is virtually at an optimised condition for the duct burning Skin friction fuel Wt 0 0 engine,The very large penalty of reducing duct burner efficiency is again evident. Total fuel 19200 37120 Dressed engine weight -11300 -11300 NCREAS是Pucr B依WNG Intake,nacelle, 0 0 2 ERO DHE可 secondary nozzle weight BURNING Total powerplant weight -11300-11300 r8) EL7 Total powerplant 1b 7900 25820 plus fuel weight %TOGW 1,13% 3.69% Payload penalty,datum 5 16,1% 52,7% payload Figures tabulated are weight changes from datum dry mixed turbofan B (1b wt or Table 6-Powerplant Plus Mission Fuel Weight Comparison,Duct Burning vs Dry SCALE FACTOR ON THRBOFAN 'D 6 Mixed Turbofan at Same Total Airflow and Thrust Fig 12. Comparison of Unmixed Duct Burning (16%datum payload)compared with the dry Turbofan (D) with Dry Mixed mixed turbofan,since the decrease in Turbofan (B) engine weight due to the smaller core nearly offsets the increase in mission fuel. In view of the fact that the duct burn- However if a burner efficiency of 85%can- ing engine has roughly the same mission not be exceeded the payload penalty is over performance as the dry mixed turbofan of 50%。 Small changes in assumptions such as the same total flow and cruise TET level, a longer subsonic element in the mission it is pertinent to ask twhat is the attrac- and a further optimisation of the duct tion of this cycle?t.The answer lies in burning cycle could change the small penalty the fact that this engine can easily be of the 100%efficient duct burner into a adapted to take advantage of any benefit small advantage compared with the dry mixed there may be from the co-annular silencing turbofan for the same flow and TET but the effect. comparison will remain marginal. Reference 6 claims a reduction of 6dB to It will be seen however that no appre- ciable departure from 100%burner efficiency 8dB in jet noise compared with a single (including profile losses)can be tolerated. stream nozzle with the same specific thrust. This poses a formidable development task, and it is noted that duct burning is inFLIGHT CONDITION FOR DUCT BURNER EFFICIENCY - Condition* Mach No 100% 8 5% 1 2.0 8.0 1.5.6 2 1.2 21.6 31.6 3 0.93 -3.0 -3.0 4 0.5 -9.2 -9.2 ~ ~~~ .~ ~. ~ ~~~~ ~ ~~ ..~.. * See Table 4 I I Duct Burner I Item Efficiency I 100% 8 5% fuel Wt I 19 200 37 120 Internal performance Total fuel -11 300 -11 300 .~~. Intake, nacelle, secondary nozzle weight Total powerplant Payload penalty, % datum 52.7% payload Class I11 (beyond 1985) of the ICAO Working Group technology classification. Figure 12 shows the effect of changing the scale factor of the duct burning version weight and payload comparison with engine E. With zero duct burning the engine must be scaled up slightly to meet the required thrust level, due to the loss of thrust from deletion of mixing. There is a significant payload penalty arising from the higher weight of the considerably higher total flow engine, and from the sfc penalty due to not mixing. As the scale factor is reduced the duct burning must be increased to maintain the thrust. Initially the decrease in weight offsets any rise in Sfc, and the payload penalty decreases. As scale is further reduced, and duct burning increased, the increase in cruise and transonic sic becomes significant, the payload penalty reaches a minimum and rises again. Thus there is an optimum amount of duct burning, and hence engine scale. For 100% burner efficiency it will be seen that the scale to give the same flow as engine B is very near the optimum. Thus the first comparison at equal total flow is virtually at an optimised condition for the duct burning engine. The very large penalty of reducing duct burner efficiency is again evident. of engine D on the powerplant plus fuel L Figures tabulated are wezght changes from datum dry mixed turbofan B (lb wt or %) Table 6 - Powerplant Plus Mission Fuel Weiqht Comparison.Duct Burninq vs Dry Mixed Turbofan at Same Total Airflow and Thrust (16% datum payload) compared with the dry mixed turbofan, since the decrease in engine weight due to the smaller core nearly offsets the increase in mission fuel. However if a burner efficiency of 85% cannot be exceeded the payload penalty is over 50%. Small changes in assumptions such as a longer subsonic element in the mission and a further optimisation of the duct burning cycle could change the small penalty of the 100% efficient duct burner into a small advantage compared with the dry mixed turbofan for the same flow and TET but the comparison will remain marginal. In view of the fact that the duct burning engine has roughly the same mission performance as the dry mixed turbofan of the same total flow and cruise TET level, it is pertinent to ask ‘what is the attraction of this cycle71. The answer lies in the fact that this engine can easily be adapted to take advantage of any benefit there may be from the co-annular silencing effect. Reference 6 claims a reduction of 6dB to L ~~ ~ It will be Seen however that no apPreciable departure from 100% burner efficiency Iincludina Drofile losses) can be tolerated. 8dB in jet noise compared with a single stream nozzle with the same specific thrust. .-- -. This poses a formidable development task, and it is noted that duct burning is in 8