正在加载图片...

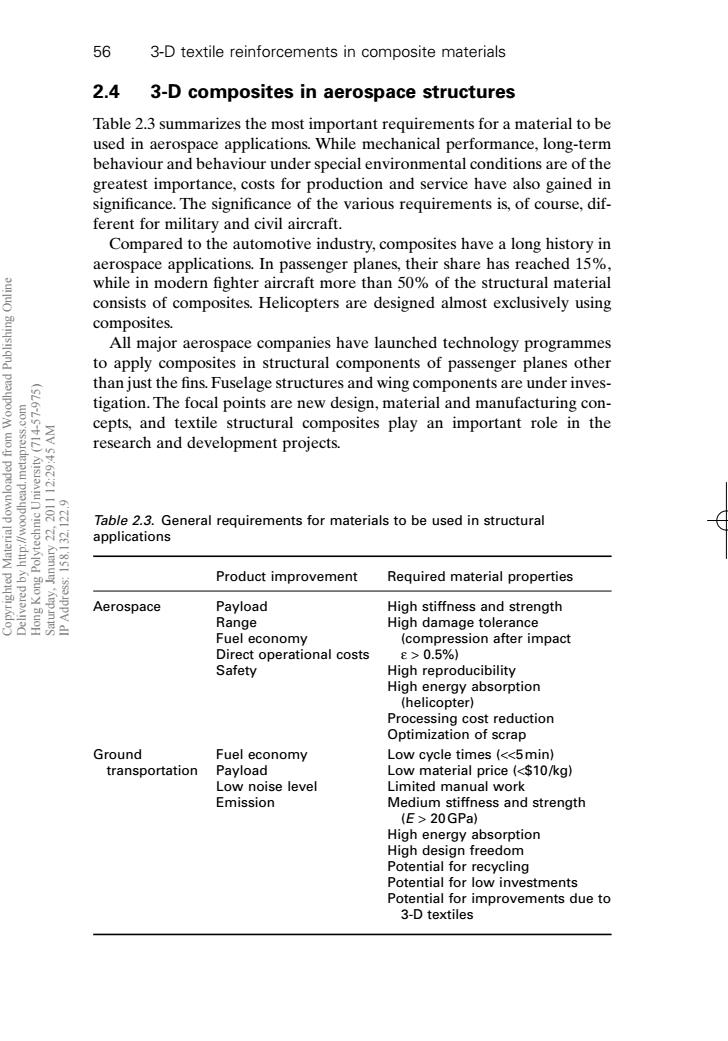

56 3-D textile reinforcements in composite materials 2.4 3-D composites in aerospace structures Table 2.3 summarizes the most important requirements for a material to be used in aerospace applications.While mechanical performance,long-term behaviour and behaviour under special environmental conditions are of the greatest importance,costs for production and service have also gained in significance.The significance of the various requirements is,of course,dif- ferent for military and civil aircraft. Compared to the automotive industry,composites have a long history in aerospace applications.In passenger planes,their share has reached 15%, while in modern fighter aircraft more than 50%of the structural material consists of composites.Helicopters are designed almost exclusively using composites. All major aerospace companies have launched technology programmes to apply composites in structural components of passenger planes other than just the fins.Fuselage structures and wing components are under inves- tigation.The focal points are new design,material and manufacturing con- cepts,and textile structural composites play an important role in the research and development projects. Table 2.3.General requirements for materials to be used in structural 号周 applications :dny Product improvement Required material properties Aerospace Payload High stiffness and strength Range High damage tolerance Fuel economy (compression after impact Direct operational costs e>0.5%) Safety High reproducibility High energy absorption (helicopter) Processing cost reduction Optimization of scrap Ground Fuel economy Low cycle times (<<5min) transportation Payload Low material price (<$10/kg) Low noise level Limited manual work Emission Medium stiffness and strength (E>20GPa) High energy absorption High design freedom Potential for recycling Potential for low investments Potential for improvements due to 3-D textiles2.4 3-D composites in aerospace structures Table 2.3 summarizes the most important requirements for a material to be used in aerospace applications. While mechanical performance, long-term behaviour and behaviour under special environmental conditions are of the greatest importance, costs for production and service have also gained in significance. The significance of the various requirements is, of course, different for military and civil aircraft. Compared to the automotive industry, composites have a long history in aerospace applications. In passenger planes, their share has reached 15%, while in modern fighter aircraft more than 50% of the structural material consists of composites. Helicopters are designed almost exclusively using composites. All major aerospace companies have launched technology programmes to apply composites in structural components of passenger planes other than just the fins. Fuselage structures and wing components are under investigation. The focal points are new design, material and manufacturing concepts, and textile structural composites play an important role in the research and development projects. 56 3-D textile reinforcements in composite materials Table 2.3. General requirements for materials to be used in structural applications Product improvement Required material properties Aerospace Payload High stiffness and strength Range High damage tolerance Fuel economy (compression after impact Direct operational costs e > 0.5%) Safety High reproducibility High energy absorption (helicopter) Processing cost reduction Optimization of scrap Ground Fuel economy Low cycle times (<<5min) transportation Payload Low material price (<$10/kg) Low noise level Limited manual work Emission Medium stiffness and strength (E > 20GPa) High energy absorption High design freedom Potential for recycling Potential for low investments Potential for improvements due to 3-D textiles RIC2 7/10/99 7:25 PM Page 56 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:29:45 AM IP Address: 158.132.122.9