正在加载图片...

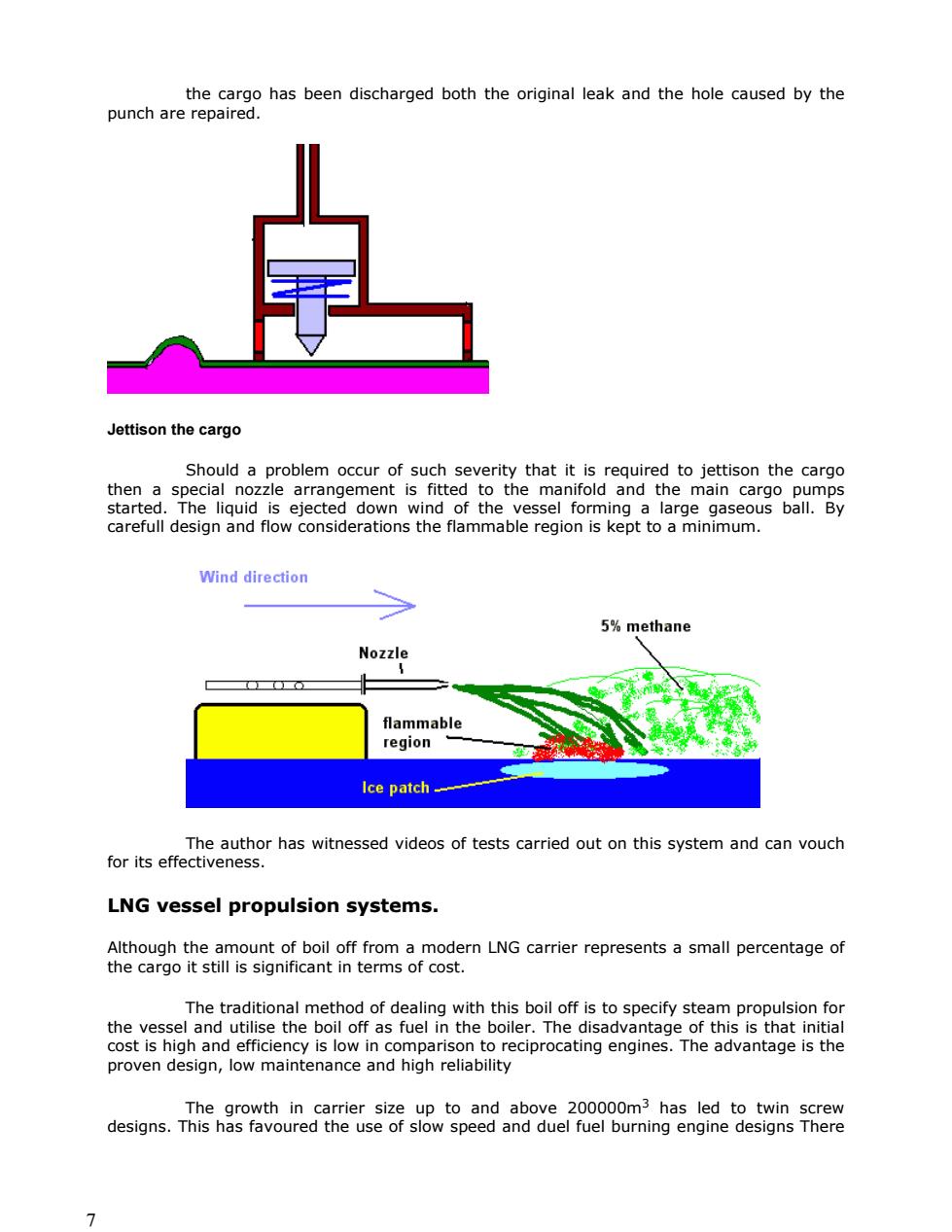

the cargo has been discharged both the original leak and the hole caused by the punch are repaired. Jettison the cargo Should a problem occur of such severity that it is required to jettison the cargo to the man odnagthgemgse8g°b8mBy Wind direction 5%methane flammable region Ice patch_ LNG vessel propulsion systems etame50ate9 percentageof of boil off fro The traditional method of dealing with this boil off is to specify steam propulsion for the vessel and utilise the boil off as fuel in the boiler.The disadvantage of this is that initial cost is high and efficiency is low in comparison to reciprocating engines.The advantage is the proven design,low maintenance and high reliability > the cargo has been discharged both the original leak and the hole caused by the punch are repaired. Jettison the cargo Should a problem occur of such severity that it is required to jettison the cargo then a special nozzle arrangement is fitted to the manifold and the main cargo pumps started. The liquid is ejected down wind of the vessel forming a large gaseous ball. By carefull design and flow considerations the flammable region is kept to a minimum. The author has witnessed videos of tests carried out on this system and can vouch for its effectiveness. LNG vessel propulsion systems. Although the amount of boil off from a modern LNG carrier represents a small percentage of the cargo it still is significant in terms of cost. The traditional method of dealing with this boil off is to specify steam propulsion for the vessel and utilise the boil off as fuel in the boiler. The disadvantage of this is that initial cost is high and efficiency is low in comparison to reciprocating engines. The advantage is the proven design, low maintenance and high reliability The growth in carrier size up to and above 200000m3 has led to twin screw designs. This has favoured the use of slow speed and duel fuel burning engine designs There 7