正在加载图片...

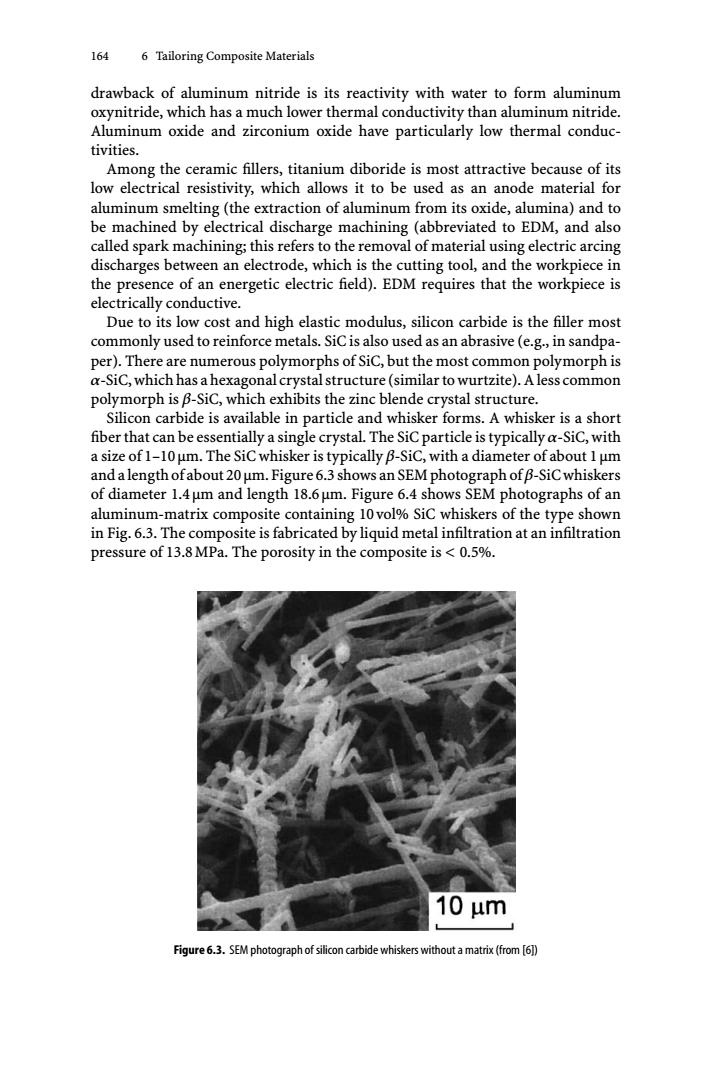

164 6 Tailoring Composite Materials drawback of aluminum nitride is its reactivity with water to form aluminum oxynitride,which has a much lower thermal conductivity than aluminum nitride Aluminum oxide and zirconium oxide have particularly low thermal conduc- tivities. Among the ceramic fillers,titanium diboride is most attractive because of its low electrical resistivity,which allows it to be used as an anode material for aluminum smelting (the extraction of aluminum from its oxide,alumina)and to be machined by electrical discharge machining (abbreviated to EDM,and also called spark machining;this refers to the removal of material using electric arcing discharges between an electrode,which is the cutting tool,and the workpiece in the presence of an energetic electric field).EDM requires that the workpiece is electrically conductive. Due to its low cost and high elastic modulus,silicon carbide is the filler most commonly used to reinforce metals.SiC is also used as an abrasive(e.g.,in sandpa- per).There are numerous polymorphs of SiC,but the most common polymorph is a-SiC,which has a hexagonal crystal structure(similar to wurtzite).Aless common polymorph is B-SiC,which exhibits the zinc blende crystal structure. Silicon carbide is available in particle and whisker forms.A whisker is a short fiber that can be essentially a single crystal.The SiC particle is typically a-SiC,with a size of 1-10 um.The SiC whisker is typically B-SiC,with a diameter of about 1 um and a length ofabout 20 um.Figure 6.3 shows an SEM photograph ofB-SiC whiskers of diameter 1.4 um and length 18.6 um.Figure 6.4 shows SEM photographs of an aluminum-matrix composite containing 10 vol%SiC whiskers of the type shown in Fig.6.3.The composite is fabricated by liquid metal infiltration at an infiltration pressure of 13.8 MPa.The porosity in the composite is 0.5%. 10 um Figure 6.3.SEM photograph of silicon carbide whiskers without a matrix (from [6])164 6 Tailoring Composite Materials drawback of aluminum nitride is its reactivity with water to form aluminum oxynitride, which has a much lower thermal conductivity than aluminum nitride. Aluminum oxide and zirconium oxide have particularly low thermal conductivities. Among the ceramic fillers, titanium diboride is most attractive because of its low electrical resistivity, which allows it to be used as an anode material for aluminum smelting (the extraction of aluminum from its oxide, alumina) and to be machined by electrical discharge machining (abbreviated to EDM, and also called spark machining; this refers to the removal of material using electric arcing discharges between an electrode, which is the cutting tool, and the workpiece in the presence of an energetic electric field). EDM requires that the workpiece is electrically conductive. Due to its low cost and high elastic modulus, silicon carbide is the filler most commonly used to reinforce metals. SiC is also used as an abrasive (e.g., in sandpaper). There are numerous polymorphs of SiC, but the most common polymorph is α-SiC, which has a hexagonal crystal structure (similar to wurtzite). A less common polymorph is β-SiC, which exhibits the zinc blende crystal structure. Silicon carbide is available in particle and whisker forms. A whisker is a short fiber that can be essentially a single crystal. The SiC particle is typically α-SiC, with a size of 1–10μm. The SiC whisker is typically β-SiC, with a diameter of about 1μm and a length of about 20μm. Figure 6.3 shows an SEM photograph of β-SiC whiskers of diameter 1.4μm and length 18.6μm. Figure 6.4 shows SEM photographs of an aluminum-matrix composite containing 10vol% SiC whiskers of the type shown in Fig. 6.3. The composite is fabricated by liquid metal infiltration at an infiltration pressure of 13.8MPa. The porosity in the composite is < 0.5%. Figure 6.3. SEM photograph of silicon carbide whiskers without a matrix (from [6])