正在加载图片...

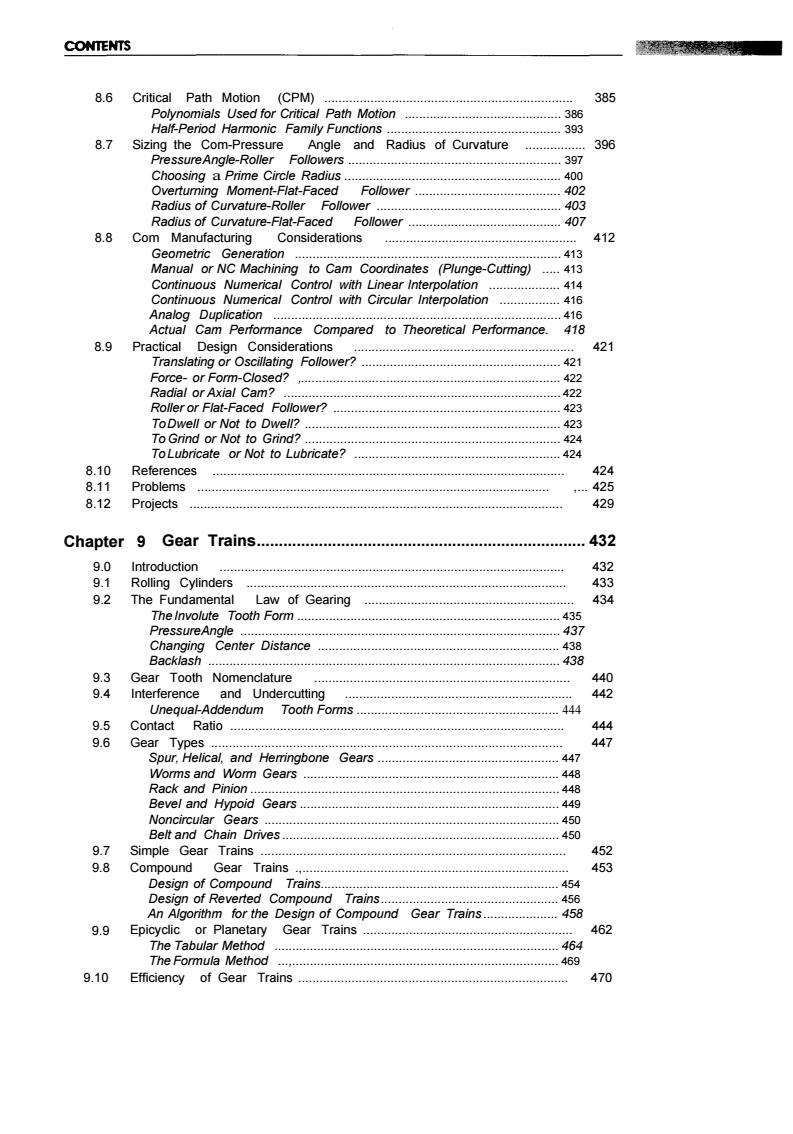

CONTENTS 8.6 Critical Path Motion (CPM)...... 385 Polynomials Used for Critical Path Motion .386 Half-Period Harmonic Family Functions................393 8.7 Sizing the Com-Pressure Angle and Radius of Curvature 396 PressureAngle-Roller Followers........ .397 Choosing a Prime Circle Radius.400 Overtuming Moment-Flat-Faced Follower .402 Radius of Curvature-Roller Follower 403 Radius of Curvature-Flat-Faced Follower.407 8.8 Com Manufacturing Considerations 4-44e…044-44e…0404-44e…e444-44e…=404-440…04044440…040 412 Geometnc Generation..413 Manual or NC Machining to Cam Coordinates (Plunge-Cutting) ..413 Continuous Numerical Control with Linear Interpolation .414 Continuous Numerical Control with Circular Interpolation ...416 Analog Duplication ..416 Actual Cam Performance Compared to Theoretical Performance.418 8.9 Practical Design Considerations 421 Translating or Oscillating Follower? 421 Force-or Form-Closed? …422 Radial or Axial Cam?… .422 Roller or Flat-Faced Follower? 423 ToDwell or Not to Dwenl? 423 To Grind or Not to Grind? 424 To Lubricate or Not to Lubricate? .424 8.10 References 424 8.11 Problems …425 8.12 Projects 429 Chapter 9 Gear Trains........ 432 9.0 Introduction 432 9.1 Rolling Cylinders 433 9.2 The Fundamental Law of Gearing 434 The Involute Tooth Form. 35 PressureAngle 37 Changing Center Distance 438 Backlash.… 438 9.3 Gear Tooth Nomenclature 440 9.4 Interference and Undercutting 442 Unequal-Addendum Tooth Forms 444 9.5 Contact Ratio 444 9.6 Gear Types… 447 Spur,Helical,and Hemingbone Gears. .447 Worms and Wom Gears448 Rack and Pinion...... .448 Bevel and Hypoid Gears....... 449 Noncircular Gears ................... 450 Belt and Chain Drives............... ...450 9.7 Simple Gear Trains ......... 452 9.8 Compound Gear Trains................................................ 453 Design of Compound Trains.... .454 Design of Reverted Compound Trains...... .456 An Algorithm for the Design of Compound Gear Trains..................... .458 9.9 Epicyclic or Planetary Gear Trains........ 462 The Tabular Method The Formula Method ,.469 9.10 Efficiency of Gear Trains...... 4708.6 Critical Path Motion (CPM) ...................................................................... 385 Polynomials Used for Critical Path Motion ............................................ 386 Half-Period Harmonic Family Functions ................................................. 393 8.7 Sizing the Com-Pressure Angle and Radius of Curvature ................. 396 PressureAngle-Roller Followers ............................................................ 397 Choosing a Prime Circle Radius ............................................................. 400 Overturning Moment-Flat-Faced Follower ......................................... 402 Radius of Curvature-Roller Follower .................................................... 403 Radius of Curvature-Flat-Faced Follower ........................................... 407 8.8 Com Manufacturing Considerations ...................................................... 412 Geometric Generation ........................................................................... 413 Manual or NC Machining to Cam Coordinates (Plunge-Cutting) ..... 413 Continuous Numerical Control with Linear Interpolation .................... 414 Continuous Numerical Control with Circular Interpolation ................. 416 Analog Duplication ................................................................................. 416 Actual Cam Performance Compared to Theoretical Performance. 418 8.9 Practical Design Considerations .............................................................. 421 Translating or Oscillating Follower? ........................................................ 421 Force- or Form-Closed? ,......................................................................... 422 Radial or Axial Cam? .............................................................................. 422 Roller or Flat-Faced Follower? ................................................................ 423 ToDwell or Not to Dwell? ........................................................................ 423 ToGrind or Not to Grind? ........................................................................ 424 ToLubricate or Not to Lubricate? .......................................................... 424 8.10 References ................................................................................................... 424 8.11 Problems ................................................................................................... ,... 425 8.12 Projects ......................................................................................................... 429 Chapter 9 Gear Trains.......................................................................... 432 9.0 Introduction ................................................................................................. 432 9.1 Rolling Cylinders .......................................................................................... 433 9.2 The Fundamental Law of Gearing ........................................................... 434 TheInvolute Tooth Form .......................................................................... 435 PressureAngle .......................................................................................... 437 Changing Center Distance .................................................................... 438 Backlash ................................................................................................... 438 9.3 Gear Tooth Nomenclature ........................................................................ 440 9.4 Interference and Undercutting ................................................................ 442 Unequal-Addendum Tooth Forms ......................................................... 444 9.5 Contact Ratio .............................................................................................. 444 9.6 Gear Types ................................................................................................... 447 Spur, Helical, and Herringbone Gears ................................................... 447 Worms and Worm Gears ........................................................................ 448 Rack and Pinion ....................................................................................... 448 Bevel and Hypoid Gears ......................................................................... 449 Noncircular Gears ................................................................................... 450 Belt and Chain Drives .............................................................................. 450 9.7 Simple Gear Trains ...................................................................................... 452 9.8 Compound Gear Trains .,........................................................................... 453 Design of Compound Trains................................................................... 454 Design of Reverted Compound Trains.................................................. 456 An Algorithm for the Design of Compound Gear Trains ..................... 458 9.9 Epicyclic or Planetary Gear Trains ........................................................... 462 The Tabular Method ................................................................................ 464 The Formula Method ...,........................................................................... 469 9.10 Efficiency of Gear Trains ............................................................................ 470