正在加载图片...

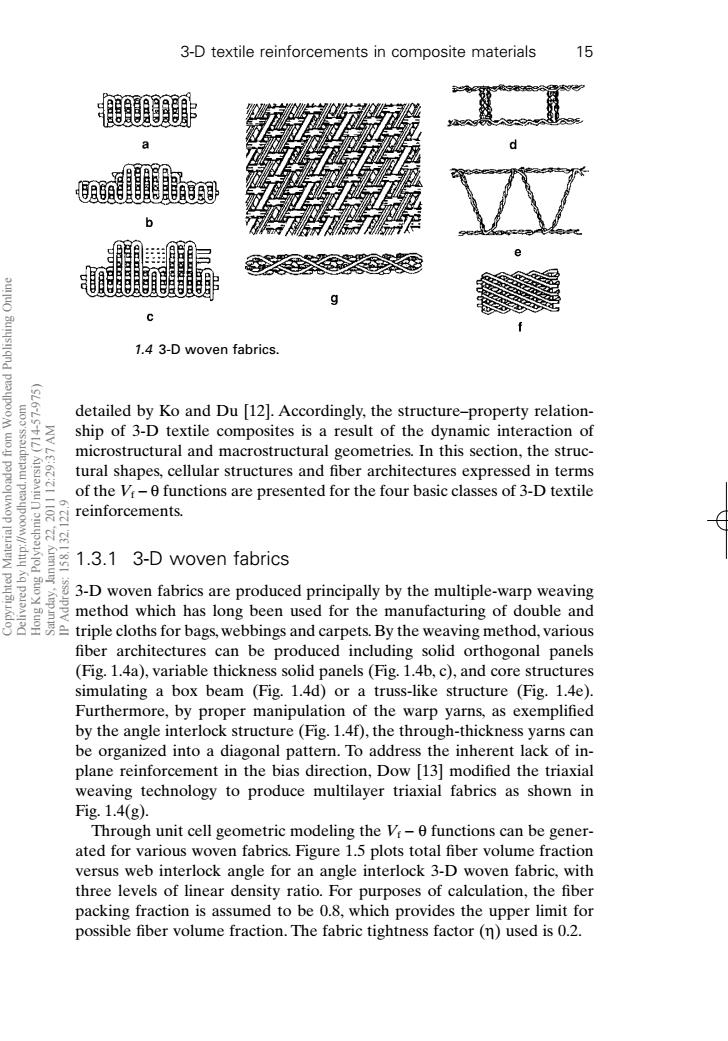

3-D textile reinforcements in composite materials 15 a b 1.4 3-D woven fabrics. detailed by Ko and Du [12].Accordingly,the structure-property relation- ship of 3-D textile composites is a result of the dynamic interaction of microstructural and macrostructural geometries.In this section,the struc- tural shapes,cellular structures and fiber architectures expressed in terms 2-10 of the Vr-0 functions are presented for the four basic classes of 3-D textile reinforcements. 1.3.1 3-D woven fabrics 3-D woven fabrics are produced principally by the multiple-warp weaving method which has long been used for the manufacturing of double and triple cloths for bags,webbings and carpets.By the weaving method,various fiber architectures can be produced including solid orthogonal panels (Fig.1.4a),variable thickness solid panels(Fig.1.4b,c),and core structures simulating a box beam (Fig.1.4d)or a truss-like structure (Fig.1.4e). Furthermore,by proper manipulation of the warp yarns,as exemplified by the angle interlock structure (Fig.1.4f),the through-thickness yarns can be organized into a diagonal pattern.To address the inherent lack of in- plane reinforcement in the bias direction,Dow [13]modified the triaxial weaving technology to produce multilayer triaxial fabrics as shown in Fig.1.4(g). Through unit cell geometric modeling the Vr-0 functions can be gener- ated for various woven fabrics.Figure 1.5 plots total fiber volume fraction versus web interlock angle for an angle interlock 3-D woven fabric,with three levels of linear density ratio.For purposes of calculation,the fiber packing fraction is assumed to be 0.8,which provides the upper limit for possible fiber volume fraction.The fabric tightness factor(n)used is 0.2.detailed by Ko and Du [12]. Accordingly, the structure–property relationship of 3-D textile composites is a result of the dynamic interaction of microstructural and macrostructural geometries. In this section, the structural shapes, cellular structures and fiber architectures expressed in terms of the Vf - q functions are presented for the four basic classes of 3-D textile reinforcements. 1.3.1 3-D woven fabrics 3-D woven fabrics are produced principally by the multiple-warp weaving method which has long been used for the manufacturing of double and triple cloths for bags, webbings and carpets. By the weaving method, various fiber architectures can be produced including solid orthogonal panels (Fig. 1.4a), variable thickness solid panels (Fig. 1.4b, c), and core structures simulating a box beam (Fig. 1.4d) or a truss-like structure (Fig. 1.4e). Furthermore, by proper manipulation of the warp yarns, as exemplified by the angle interlock structure (Fig. 1.4f), the through-thickness yarns can be organized into a diagonal pattern. To address the inherent lack of inplane reinforcement in the bias direction, Dow [13] modified the triaxial weaving technology to produce multilayer triaxial fabrics as shown in Fig. 1.4(g). Through unit cell geometric modeling the Vf - q functions can be generated for various woven fabrics. Figure 1.5 plots total fiber volume fraction versus web interlock angle for an angle interlock 3-D woven fabric, with three levels of linear density ratio. For purposes of calculation, the fiber packing fraction is assumed to be 0.8, which provides the upper limit for possible fiber volume fraction. The fabric tightness factor (h) used is 0.2. 3-D textile reinforcements in composite materials 15 1.4 3-D woven fabrics. RIC1 7/10/99 7:15 PM Page 15 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:29:37 AM IP Address: 158.132.122.9