正在加载图片...

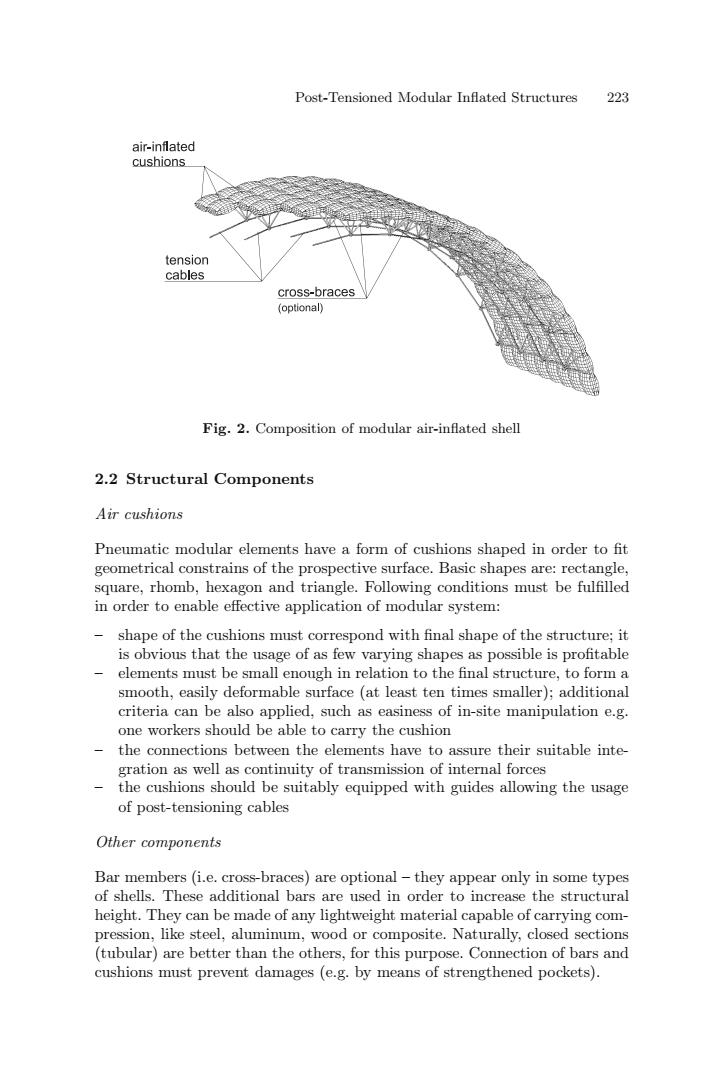

Post-Tensioned Modular Inflated Structures 223 air-inflated cushions tension cables cross-braces (optional) Fig.2.Composition of modular air-inflated shell 2.2 Structural Components Air cushions Pneumatic modular elements have a form of cushions shaped in order to fit geometrical constrains of the prospective surface.Basic shapes are:rectangle, square,rhomb,hexagon and triangle.Following conditions must be fulfilled in order to enable effective application of modular system: shape of the cushions must correspond with final shape of the structure;it is obvious that the usage of as few varying shapes as possible is profitable elements must be small enough in relation to the final structure,to form a smooth,easily deformable surface(at least ten times smaller);additional criteria can be also applied,such as easiness of in-site manipulation e.g. one workers should be able to carry the cushion the connections between the elements have to assure their suitable inte- gration as well as continuity of transmission of internal forces the cushions should be suitably equipped with guides allowing the usage of post-tensioning cables Other components Bar members (i.e.cross-braces)are optional-they appear only in some types of shells.These additional bars are used in order to increase the structural height.They can be made of any lightweight material capable of carrying com- pression,like steel,aluminum,wood or composite.Naturally,closed sections (tubular)are better than the others,for this purpose.Connection of bars and cushions must prevent damages (e.g.by means of strengthened pockets).Post-Tensioned Modular Inflated Structures 223 Fig. 2. Composition of modular air-inflated shell 2.2 Structural Components Air cushions Pneumatic modular elements have a form of cushions shaped in order to fit geometrical constrains of the prospective surface. Basic shapes are: rectangle, square, rhomb, hexagon and triangle. Following conditions must be fulfilled in order to enable effective application of modular system: – shape of the cushions must correspond with final shape of the structure; it is obvious that the usage of as few varying shapes as possible is profitable – elements must be small enough in relation to the final structure, to form a smooth, easily deformable surface (at least ten times smaller); additional criteria can be also applied, such as easiness of in-site manipulation e.g. one workers should be able to carry the cushion – the connections between the elements have to assure their suitable integration as well as continuity of transmission of internal forces – the cushions should be suitably equipped with guides allowing the usage of post-tensioning cables Other components Bar members (i.e. cross-braces) are optional – they appear only in some types of shells. These additional bars are used in order to increase the structural height. They can be made of any lightweight material capable of carrying compression, like steel, aluminum, wood or composite. Naturally, closed sections (tubular) are better than the others, for this purpose. Connection of bars and cushions must prevent damages (e.g. by means of strengthened pockets)