正在加载图片...

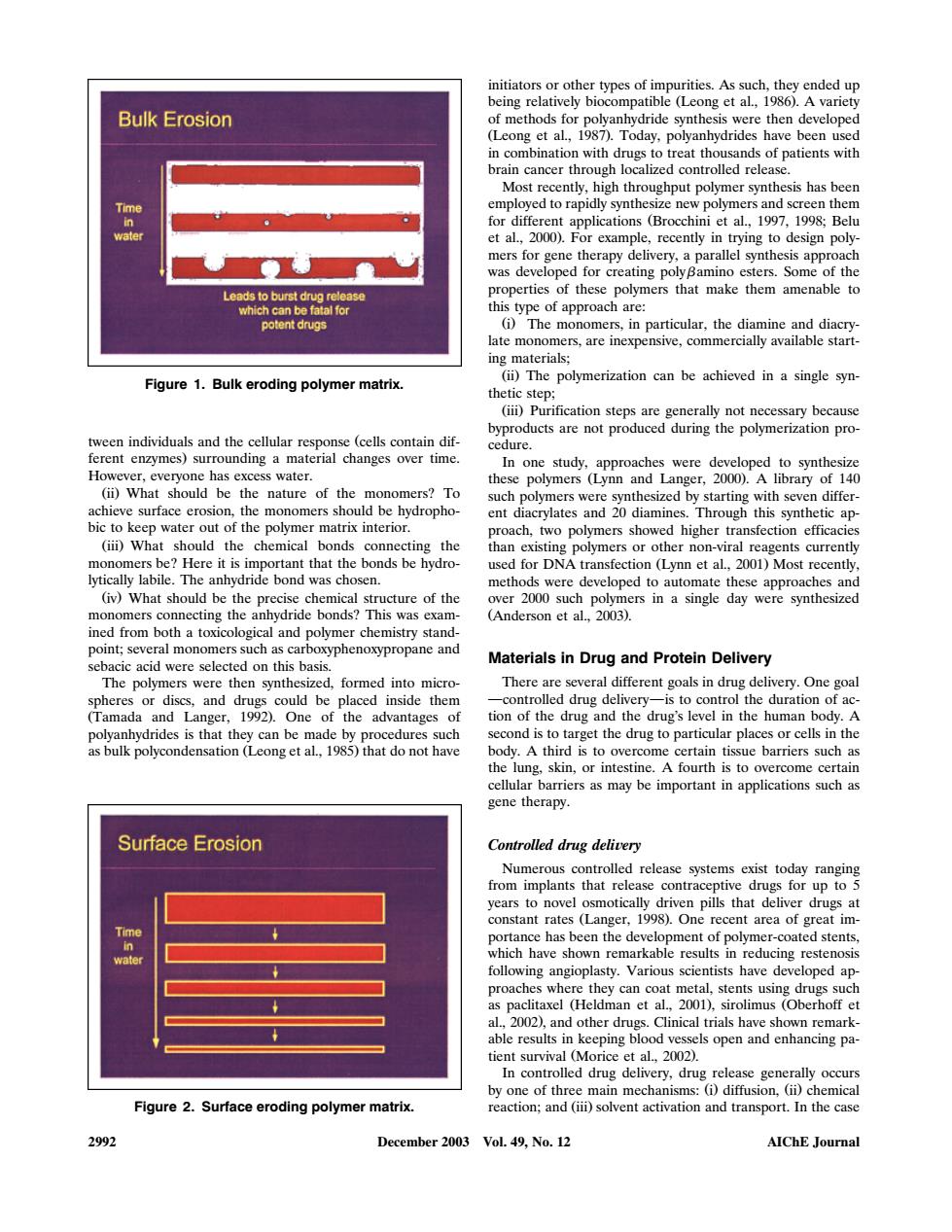

Bulk Erosion (Leong et al, )Today,polyanhydrid it sis has beer 。 for s for f the Leads to b e of approach potent drugs The monome r icular,the diamine ing materials: Figure 1.Bulk eroding polymer matri (ii)Purification steps are generally not necessary because indiv and the celular produced during the polymerio ro rent enzymes) In one study L roaches wer th arti hydroph ugh this synthetic ap 、mc)What should the中oran that the68 nds be lydme ents currenth ere it i sed for DN trar c(Lynn et al, 2001)Most recently ()What shoud be the the er 2000 such ccng th was and stand point;several mond mers epeRoypopaneand Materials in Drug and Protein Delivery There are several different goals in drug delivery.One goal be placed inside then dthe drug to co i he dur t the ond is arget the drug to particular places or cells in the ellular barriers as may be important in applications such as gene therapy. Surface Erosion Controlled drug delivery 号 s a constant rates (La e1998.0 ccent area of great im which have shown restenosi have d loped ap 0202 Figure 2.Surface eroding polymer matrix 2992 December 2003 Vol.49.No.12 AIChE Journal Figure 1. Bulk eroding polymer matrix. tween individuals and the cellular response cells contain dif- Ž ferent enzymes surrounding a material changes over time. . However, everyone has excess water. Ž . ii What should be the nature of the monomers? To achieve surface erosion, the monomers should be hydrophobic to keep water out of the polymer matrix interior. Ž . iii What should the chemical bonds connecting the monomers be? Here it is important that the bonds be hydrolytically labile. The anhydride bond was chosen. Ž . iv What should be the precise chemical structure of the monomers connecting the anhydride bonds? This was examined from both a toxicological and polymer chemistry standpoint; several monomers such as carboxyphenoxypropane and sebacic acid were selected on this basis. The polymers were then synthesized, formed into microspheres or discs, and drugs could be placed inside them Ž . Tamada and Langer, 1992 . One of the advantages of polyanhydrides is that they can be made by procedures such as bulk polycondensation Leong et al., 1985 that do not have Ž . Figure 2. Surface eroding polymer matrix. initiators or other types of impurities. As such, they ended up being relatively biocompatible Leong et al., 1986 . A variety Ž . of methods for polyanhydride synthesis were then developed Ž . Leong et al., 1987 . Today, polyanhydrides have been used in combination with drugs to treat thousands of patients with brain cancer through localized controlled release. Most recently, high throughput polymer synthesis has been employed to rapidly synthesize new polymers and screen them for different applications Brocchini et al., 1997, 1998; Belu Ž et al., 2000 . For example, recently in trying to design poly- . mers for gene therapy delivery, a parallel synthesis approach was developed for creating polyamino esters. Some of the properties of these polymers that make them amenable to this type of approach are: Ž .i The monomers, in particular, the diamine and diacrylate monomers, are inexpensive, commercially available starting materials; Ž . ii The polymerization can be achieved in a single synthetic step; Ž . iii Purification steps are generally not necessary because byproducts are not produced during the polymerization procedure. In one study, approaches were developed to synthesize these polymers Lynn and Langer, 2000 . A library of 140 Ž . such polymers were synthesized by starting with seven different diacrylates and 20 diamines. Through this synthetic approach, two polymers showed higher transfection efficacies than existing polymers or other non-viral reagents currently used for DNA transfection Lynn et al., 2001 Most recently, Ž . methods were developed to automate these approaches and over 2000 such polymers in a single day were synthesized Ž . Anderson et al., 2003 . Materials in Drug and Protein Delivery There are several different goals in drug delivery. One goal controlled drug deliveryis to control the duration of action of the drug and the drug’s level in the human body. A second is to target the drug to particular places or cells in the body. A third is to overcome certain tissue barriers such as the lung, skin, or intestine. A fourth is to overcome certain cellular barriers as may be important in applications such as gene therapy. Controlled drug deli©ery Numerous controlled release systems exist today ranging from implants that release contraceptive drugs for up to 5 years to novel osmotically driven pills that deliver drugs at constant rates Langer, 1998 . One recent area of great im- Ž . portance has been the development of polymer-coated stents, which have shown remarkable results in reducing restenosis following angioplasty. Various scientists have developed approaches where they can coat metal, stents using drugs such as paclitaxel Heldman et al., 2001 , sirolimus Oberhoff et Ž .Ž al., 2002 , and other drugs. Clinical trials have shown remark- . able results in keeping blood vessels open and enhancing patient survival Morice et al., 2002 . Ž . In controlled drug delivery, drug release generally occurs by one of three main mechanisms: i diffusion, ii chemical Ž. Ž . reaction; and iii solvent activation and transport. In the case Ž . 2992 December 2003 Vol. 49, No. 12 AIChE Journal��