正在加载图片...

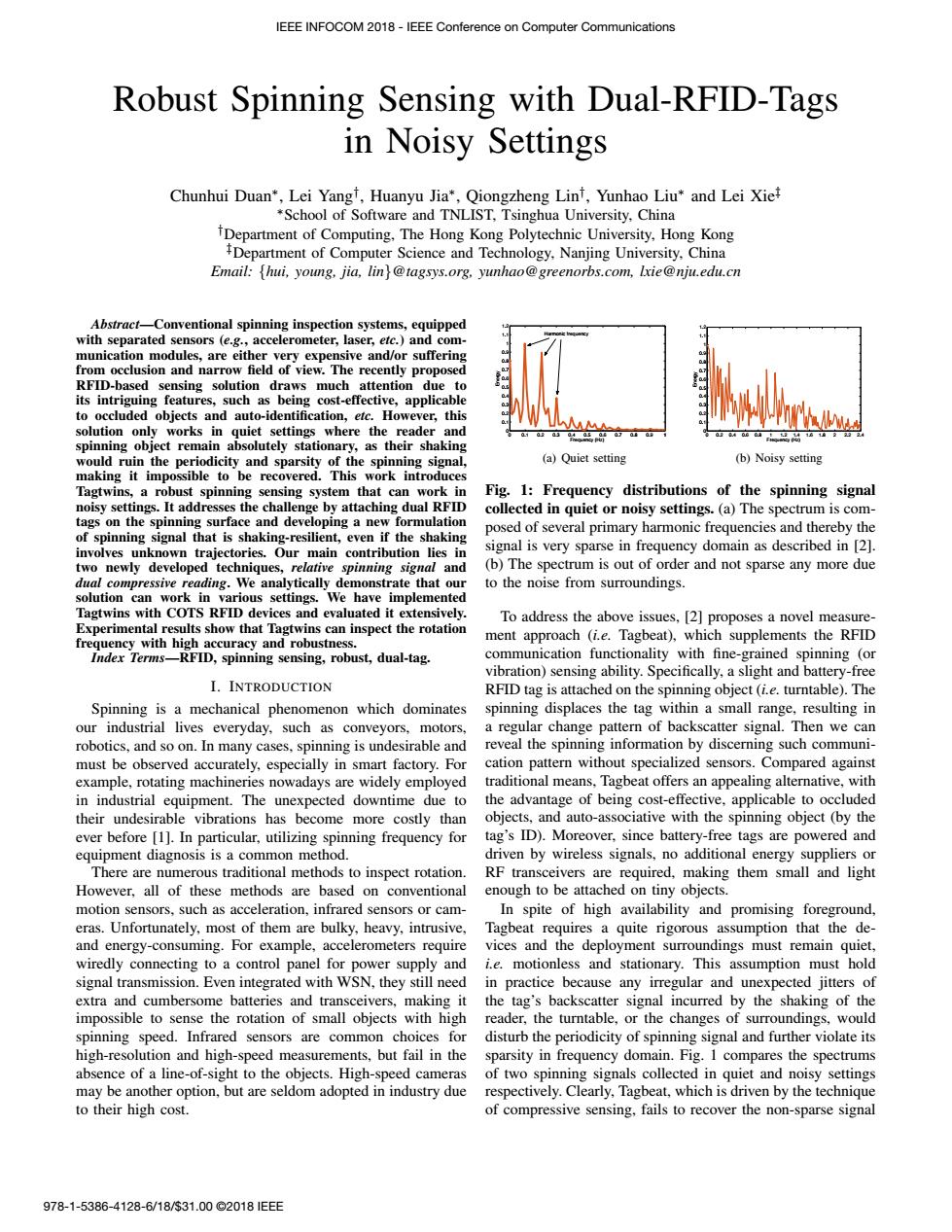

IEEE INFOCOM 2018-IEEE Conference on Computer Communications Robust Spinning Sensing with Dual-RFID-Tags in Noisy Settings Chunhui Duan*,Lei Yangt,Huanyu Jia*,Qiongzheng Lint,Yunhao Liu*and Lei Xiet *School of Software and TNLIST,Tsinghua University.China fDepartment of Computing.The Hong Kong Polytechnic University,Hong Kong FDepartment of Computer Science and Technology,Nanjing University,China Email:[hui,young,jia,lin@tagsys.org,yunhao@greenorbs.com,Ixie@nju.edu.cn Abstract-Conventional spinning inspection systems,equipped with separated sensors (e.g.,accelerometer,laser,etc.)and com- munication modules,are either very expensive and/or suffering from occlusion and narrow field of view.The recently proposed RFID-based sensing solution draws much attention due to its intriguing features,such as being cost-effective,applicable to occluded objects and auto-identification,etc.However,this solution only works in quiet settings where the reader and MA spinning object remain absolutely stationary,as their shaking would ruin the periodicity and sparsity of the spinning signal (a)Quiet setting (b)Noisy setting making it impossible to be recovered.This work introduces Tagtwins,a robust spinning sensing system that can work in Fig.1:Frequency distributions of the spinning signal noisy settings.It addresses the challenge by attaching dual RFID collected in quiet or noisy settings.(a)The spectrum is com- tags on the spinning surface and developing a new formulation of spinning signal that is shaking-resilient,even if the shaking posed of several primary harmonic frequencies and thereby the involves unknown trajectories.Our main contribution lies in signal is very sparse in frequency domain as described in [2]. two newly developed techniques,relative spinning signal and (b)The spectrum is out of order and not sparse any more due dual compressive reading.We analytically demonstrate that our to the noise from surroundings. solution can work in various settings.We have implemented Tagtwins with COTS RFID devices and evaluated it extensively. To address the above issues,[2]proposes a novel measure- Experimental results show that Tagtwins can inspect the rotation frequency with high accuracy and robustness. ment approach(i.e.Tagbeat),which supplements the RFID Index Terms-RFID,spinning sensing,robust,dual-tag. communication functionality with fine-grained spinning (or vibration)sensing ability.Specifically,a slight and battery-free I.INTRODUCTION RFID tag is attached on the spinning object(i.e.turntable).The Spinning is a mechanical phenomenon which dominates spinning displaces the tag within a small range,resulting in our industrial lives everyday,such as conveyors,motors, a regular change pattern of backscatter signal.Then we can robotics,and so on.In many cases,spinning is undesirable and reveal the spinning information by discerning such communi- must be observed accurately,especially in smart factory.For cation pattern without specialized sensors.Compared against example,rotating machineries nowadays are widely employed traditional means,Tagbeat offers an appealing alternative,with in industrial equipment.The unexpected downtime due to the advantage of being cost-effective,applicable to occluded their undesirable vibrations has become more costly than objects,and auto-associative with the spinning object(by the ever before [1].In particular,utilizing spinning frequency for tag's ID).Moreover,since battery-free tags are powered and equipment diagnosis is a common method. driven by wireless signals,no additional energy suppliers or There are numerous traditional methods to inspect rotation.RF transceivers are required,making them small and light However,all of these methods are based on conventional enough to be attached on tiny objects. motion sensors,such as acceleration,infrared sensors or cam- In spite of high availability and promising foreground, eras.Unfortunately,most of them are bulky,heavy,intrusive, Tagbeat requires a quite rigorous assumption that the de- and energy-consuming.For example,accelerometers require vices and the deployment surroundings must remain quiet, wiredly connecting to a control panel for power supply and i.e.motionless and stationary.This assumption must hold signal transmission.Even integrated with WSN,they still need in practice because any irregular and unexpected jitters of extra and cumbersome batteries and transceivers,making it the tag's backscatter signal incurred by the shaking of the impossible to sense the rotation of small objects with high reader,the turntable,or the changes of surroundings,would spinning speed.Infrared sensors are common choices for disturb the periodicity of spinning signal and further violate its high-resolution and high-speed measurements,but fail in the sparsity in frequency domain.Fig.I compares the spectrums absence of a line-of-sight to the objects.High-speed cameras of two spinning signals collected in quiet and noisy settings may be another option,but are seldom adopted in industry due respectively.Clearly,Tagbeat,which is driven by the technique to their high cost. of compressive sensing,fails to recover the non-sparse signal 978-1-5386-4128-6/18/$31.00©20181EEERobust Spinning Sensing with Dual-RFID-Tags in Noisy Settings Chunhui Duan⇤, Lei Yang†, Huanyu Jia⇤, Qiongzheng Lin†, Yunhao Liu⇤ and Lei Xie‡ ⇤School of Software and TNLIST, Tsinghua University, China †Department of Computing, The Hong Kong Polytechnic University, Hong Kong ‡Department of Computer Science and Technology, Nanjing University, China Email: {hui, young, jia, lin}@tagsys.org, yunhao@greenorbs.com, lxie@nju.edu.cn Abstract—Conventional spinning inspection systems, equipped with separated sensors (e.g., accelerometer, laser, etc.) and communication modules, are either very expensive and/or suffering from occlusion and narrow field of view. The recently proposed RFID-based sensing solution draws much attention due to its intriguing features, such as being cost-effective, applicable to occluded objects and auto-identification, etc. However, this solution only works in quiet settings where the reader and spinning object remain absolutely stationary, as their shaking would ruin the periodicity and sparsity of the spinning signal, making it impossible to be recovered. This work introduces Tagtwins, a robust spinning sensing system that can work in noisy settings. It addresses the challenge by attaching dual RFID tags on the spinning surface and developing a new formulation of spinning signal that is shaking-resilient, even if the shaking involves unknown trajectories. Our main contribution lies in two newly developed techniques, relative spinning signal and dual compressive reading. We analytically demonstrate that our solution can work in various settings. We have implemented Tagtwins with COTS RFID devices and evaluated it extensively. Experimental results show that Tagtwins can inspect the rotation frequency with high accuracy and robustness. Index Terms—RFID, spinning sensing, robust, dual-tag. I. INTRODUCTION Spinning is a mechanical phenomenon which dominates our industrial lives everyday, such as conveyors, motors, robotics, and so on. In many cases, spinning is undesirable and must be observed accurately, especially in smart factory. For example, rotating machineries nowadays are widely employed in industrial equipment. The unexpected downtime due to their undesirable vibrations has become more costly than ever before [1]. In particular, utilizing spinning frequency for equipment diagnosis is a common method. There are numerous traditional methods to inspect rotation. However, all of these methods are based on conventional motion sensors, such as acceleration, infrared sensors or cameras. Unfortunately, most of them are bulky, heavy, intrusive, and energy-consuming. For example, accelerometers require wiredly connecting to a control panel for power supply and signal transmission. Even integrated with WSN, they still need extra and cumbersome batteries and transceivers, making it impossible to sense the rotation of small objects with high spinning speed. Infrared sensors are common choices for high-resolution and high-speed measurements, but fail in the absence of a line-of-sight to the objects. High-speed cameras may be another option, but are seldom adopted in industry due to their high cost. 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2 Frequency (Hz) Energy Harmonic frequency (a) Quiet setting 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 2.2 2.4 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2 Frequency (Hz) Energy (b) Noisy setting Fig. 1: Frequency distributions of the spinning signal collected in quiet or noisy settings. (a) The spectrum is composed of several primary harmonic frequencies and thereby the signal is very sparse in frequency domain as described in [2]. (b) The spectrum is out of order and not sparse any more due to the noise from surroundings. To address the above issues, [2] proposes a novel measurement approach (i.e. Tagbeat), which supplements the RFID communication functionality with fine-grained spinning (or vibration) sensing ability. Specifically, a slight and battery-free RFID tag is attached on the spinning object (i.e. turntable). The spinning displaces the tag within a small range, resulting in a regular change pattern of backscatter signal. Then we can reveal the spinning information by discerning such communication pattern without specialized sensors. Compared against traditional means, Tagbeat offers an appealing alternative, with the advantage of being cost-effective, applicable to occluded objects, and auto-associative with the spinning object (by the tag’s ID). Moreover, since battery-free tags are powered and driven by wireless signals, no additional energy suppliers or RF transceivers are required, making them small and light enough to be attached on tiny objects. In spite of high availability and promising foreground, Tagbeat requires a quite rigorous assumption that the devices and the deployment surroundings must remain quiet, i.e. motionless and stationary. This assumption must hold in practice because any irregular and unexpected jitters of the tag’s backscatter signal incurred by the shaking of the reader, the turntable, or the changes of surroundings, would disturb the periodicity of spinning signal and further violate its sparsity in frequency domain. Fig. 1 compares the spectrums of two spinning signals collected in quiet and noisy settings respectively. Clearly, Tagbeat, which is driven by the technique of compressive sensing, fails to recover the non-sparse signal IEEE INFOCOM 2018 - IEEE Conference on Computer Communications 978-1-5386-4128-6/18/$31.00 ©2018 IEEE