正在加载图片...

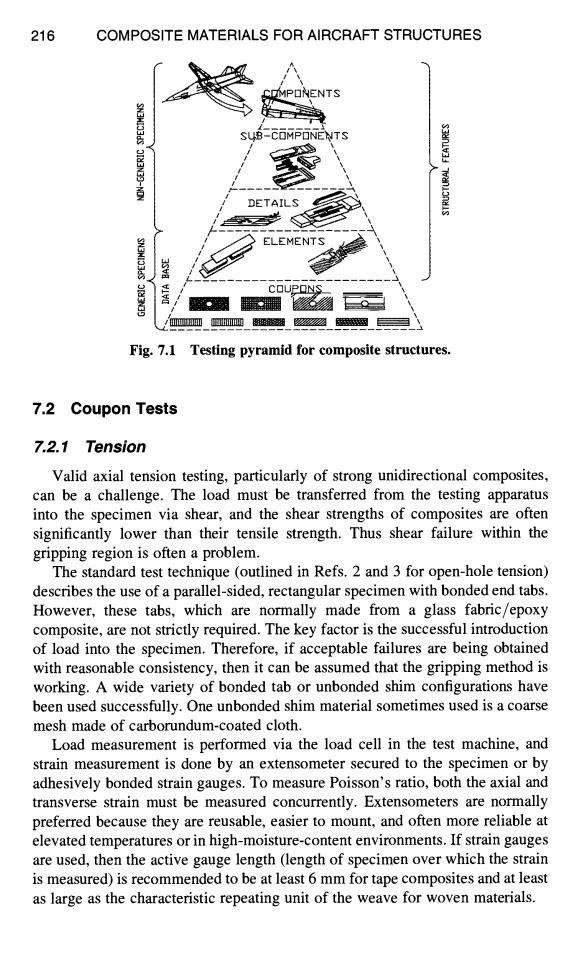

216 COMPOSITE MATERIALS FOR AIRCRAFT STRUCTURES SUB-COMPONENTS DETAILS ELEMENTS Fig.7.1 Testing pyramid for composite structures. 7.2 Coupon Tests 7.2.1 Tension Valid axial tension testing,particularly of strong unidirectional composites, can be a challenge.The load must be transferred from the testing apparatus into the specimen via shear,and the shear strengths of composites are often significantly lower than their tensile strength.Thus shear failure within the gripping region is often a problem. The standard test technique (outlined in Refs.2 and 3 for open-hole tension) describes the use of a parallel-sided,rectangular specimen with bonded end tabs. However,these tabs,which are normally made from a glass fabric/epoxy composite,are not strictly required.The key factor is the successful introduction of load into the specimen.Therefore,if acceptable failures are being obtained with reasonable consistency,then it can be assumed that the gripping method is working.A wide variety of bonded tab or unbonded shim configurations have been used successfully.One unbonded shim material sometimes used is a coarse mesh made of carborundum-coated cloth. Load measurement is performed via the load cell in the test machine,and strain measurement is done by an extensometer secured to the specimen or by adhesively bonded strain gauges.To measure Poisson's ratio,both the axial and transverse strain must be measured concurrently.Extensometers are normally preferred because they are reusable,easier to mount,and often more reliable at elevated temperatures or in high-moisture-content environments.If strain gauges are used,then the active gauge length (length of specimen over which the strain is measured)is recommended to be at least 6 mm for tape composites and at least as large as the characteristic repeating unit of the weave for woven materials.216 COMPOSITE MATERIALS FOR AIRCRAFT STRUCTURES i SUtB_CnMpnNE~ITS /", ~ \'\ I \ L__~ ~_ ........... ~ ........ / cnup_~ ~ ',, ./,,,.,.__.._.,,_,_ ...,,_,._,..-_ ~_ _~_~__ ~_ ~_'.~ Fig. 7.1 Testing pyramid for composite structures. 7.2 Coupon Tests 7.2.1 Tension Valid axial tension testing, particularly of strong unidirectional composites, can be a challenge. The load must be transferred from the testing apparatus into the specimen via shear, and the shear strengths of composites are often significantly lower than their tensile strength. Thus shear failure within the gripping region is often a problem. The standard test technique (outlined in Refs. 2 and 3 for open-hole tension) describes the use of a parallel-sided, rectangular specimen with bonded end tabs. However, these tabs, which are normally made from a glass fabric/epoxy composite, are not strictly required. The key factor is the successful introduction of load into the specimen. Therefore, if acceptable failures are being obtained with reasonable consistency, then it can be assumed that the gripping method is working. A wide variety of bonded tab or unbonded shim configurations have been used successfully. One unbonded shim material sometimes used is a coarse mesh made of carborundum-coated cloth. Load measurement is performed via the load cell in the test machine, and strain measurement is done by an extensometer secured to the specimen or by adhesively bonded strain gauges. To measure Poisson's ratio, both the axial and transverse strain must be measured concurrently. Extensometers are normally preferred because they are reusable, easier to mount, and often more reliable at elevated temperatures or in high-moisture-content environments. If strain gauges are used, then the active gauge length (length of specimen over which the strain is measured) is recommended to be at least 6 mm for tape composites and at least as large as the characteristic repeating unit of the weave for woven materials