正在加载图片...

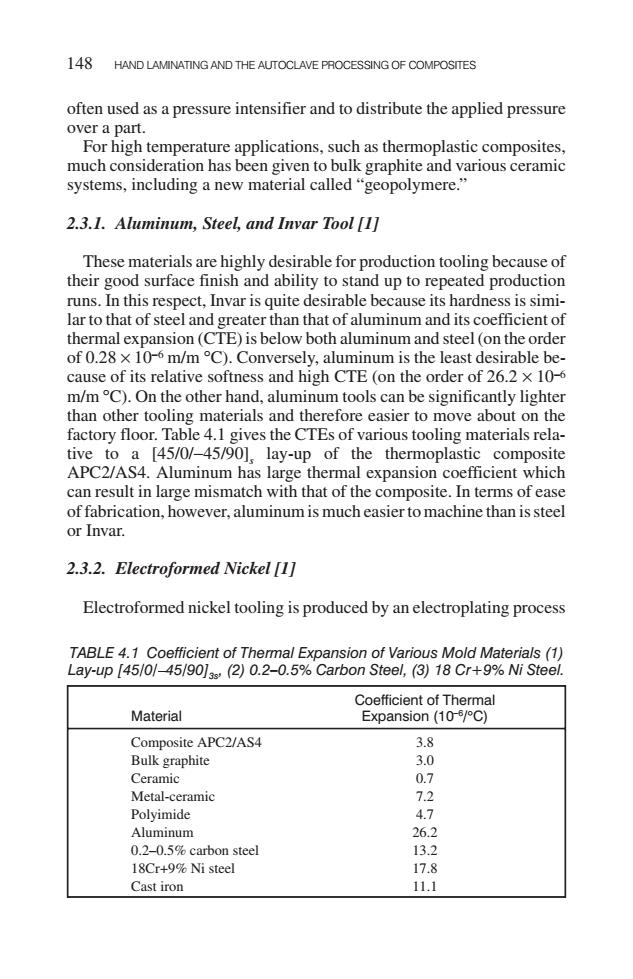

148 HAND LAMINATING AND THE AUTOCLAVE PROCESSING OF COMPOSITES often used as a pressure intensifier and to distribute the applied pressure over a part. For high temperature applications,such as thermoplastic composites, much consideration has been given to bulk graphite and various ceramic systems,including a new material called"geopolymere." 2.3.1.Aluminum,Steel,and Invar Tool [1] These materials are highly desirable for production tooling because of their good surface finish and ability to stand up to repeated production runs.In this respect,Invar is quite desirable because its hardness is simi- lar to that of steel and greater than that of aluminum and its coefficient of thermal expansion(CTE)is below both aluminum and steel (on the order of 0.28 x 10-6 m/m C).Conversely,aluminum is the least desirable be- cause of its relative softness and high CTE (on the order of 26.2 x 10- m/m C).On the other hand,aluminum tools can be significantly lighter than other tooling materials and therefore easier to move about on the factory floor.Table 4.1 gives the CTEs of various tooling materials rela- tive to a [45/0/-45/90].lay-up of the thermoplastic composite APC2/AS4.Aluminum has large thermal expansion coefficient which can result in large mismatch with that of the composite.In terms of ease of fabrication,however,aluminum is much easier to machine than is steel or Invar. 2.3.2.Electroformed Nickel [1] Electroformed nickel tooling is produced by an electroplating process TABLE 4.1 Coefficient of Thermal Expansion of Various Mold Materials(1) Lay-up [45/0/-45/90]ss,(2)0.2-0.5%Carbon Steel,(3)18 Cr+9%Ni Steel. Coefficient of Thermal Material Expansion (10/C) Composite APC2/AS4 3.8 Bulk graphite 3.0 Ceramic 0.7 Metal-ceramic 7.2 Polyimide 4.7 Aluminum 26.2 0.2-0.5%carbon steel 13.2 18Cr+9%Ni steel 17.8 Cast iron 11.1often used as a pressure intensifier and to distribute the applied pressure over a part. For high temperature applications, such as thermoplastic composites, much consideration has been given to bulk graphite and various ceramic systems, including a new material called “geopolymere.” 2.3.1. Aluminum, Steel, and Invar Tool [1] These materials are highly desirable for production tooling because of their good surface finish and ability to stand up to repeated production runs. In this respect, Invar is quite desirable because its hardness is similar to that of steel and greater than that of aluminum and its coefficient of thermal expansion (CTE) is below both aluminum and steel (on the order of 0.28 × 10−6 m/m °C). Conversely, aluminum is the least desirable because of its relative softness and high CTE (on the order of 26.2 × 10−6 m/m °C). On the other hand, aluminum tools can be significantly lighter than other tooling materials and therefore easier to move about on the factory floor. Table 4.1 gives the CTEs of various tooling materials relative to a [45/0/−45/90]s lay-up of the thermoplastic composite APC2/AS4. Aluminum has large thermal expansion coefficient which can result in large mismatch with that of the composite. In terms of ease of fabrication, however, aluminum is much easier to machine than is steel or Invar. 2.3.2. Electroformed Nickel [1] Electroformed nickel tooling is produced by an electroplating process 148 HAND LAMINATING AND THE AUTOCLAVE PROCESSING OF COMPOSITES TABLE 4.1 Coefficient of Thermal Expansion of Various Mold Materials (1) Lay-up [45/0/ 45/90]3s, (2) 0.2–0.5% Carbon Steel, (3) 18 Cr+9% Ni Steel. Material Coefficient of Thermal Expansion (10−6 /°C) Composite APC2/AS4 3.8 Bulk graphite 3.0 Ceramic 0.7 Metal-ceramic 7.2 Polyimide 4.7 Aluminum 26.2 0.2–0.5% carbon steel 13.2 18Cr+9% Ni steel 17.8 Cast iron 11.1