正在加载图片...

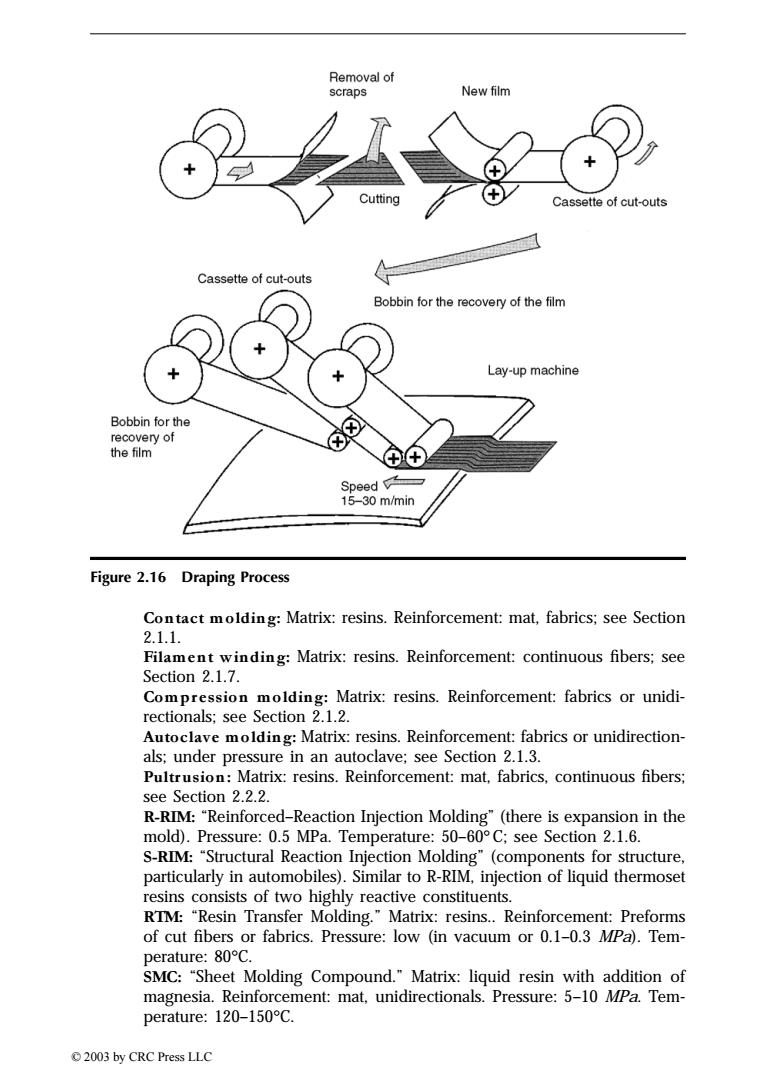

Removal of scraps New film Cutting Cassette of cut-outs Cassette of cut-outs Bobbin for the recovery of the film Lay-up machine Bobbin for the recovery of the film ⊕中 Speed 15-30m/min Figure 2.16 Draping Process Contact molding:Matrix:resins.Reinforcement:mat,fabrics;see Section 2.1.1. Filament winding:Matrix:resins.Reinforcement:continuous fibers;see Section 2.1.7. Compression molding:Matrix:resins.Reinforcement:fabrics or unidi- rectionals;see Section 2.1.2. Autoclave molding:Matrix:resins.Reinforcement:fabrics or unidirection- als;under pressure in an autoclave;see Section 2.1.3. Pultrusion:Matrix:resins.Reinforcement:mat,fabrics,continuous fibers; see Section 2.2.2. R-RIM:"Reinforced-Reaction Injection Molding"(there is expansion in the mold).Pressure:0.5 MPa.Temperature:50-60C;see Section 2.1.6. S-RIM:"Structural Reaction Injection Molding"(components for structure, particularly in automobiles).Similar to R-RIM,injection of liquid thermoset resins consists of two highly reactive constituents. RTM:"Resin Transfer Molding."Matrix:resins..Reinforcement:Preforms of cut fibers or fabrics.Pressure:low (in vacuum or 0.1-0.3 MPa).Tem- perature:80C. SMC:"Sheet Molding Compound."Matrix:liquid resin with addition of magnesia.Reinforcement:mat,unidirectionals.Pressure:5-10 MPa.Tem- perature:120-150°C. 2003 by CRC Press LLCContact molding: Matrix: resins. Reinforcement: mat, fabrics; see Section 2.1.1. Filament winding: Matrix: resins. Reinforcement: continuous fibers; see Section 2.1.7. Compression molding: Matrix: resins. Reinforcement: fabrics or unidirectionals; see Section 2.1.2. Autoclave molding: Matrix: resins. Reinforcement: fabrics or unidirectionals; under pressure in an autoclave; see Section 2.1.3. Pultrusion: Matrix: resins. Reinforcement: mat, fabrics, continuous fibers; see Section 2.2.2. R-RIM: “Reinforced–Reaction Injection Molding” (there is expansion in the mold). Pressure: 0.5 MPa. Temperature: 50–60∞C; see Section 2.1.6. S-RIM: “Structural Reaction Injection Molding” (components for structure, particularly in automobiles). Similar to R-RIM, injection of liquid thermoset resins consists of two highly reactive constituents. RTM: “Resin Transfer Molding.” Matrix: resins.. Reinforcement: Preforms of cut fibers or fabrics. Pressure: low (in vacuum or 0.1–0.3 MPa). Temperature: 80∞C. SMC: “Sheet Molding Compound.” Matrix: liquid resin with addition of magnesia. Reinforcement: mat, unidirectionals. Pressure: 5–10 MPa. Temperature: 120–150∞C. Figure 2.16 Draping Process TX846_Frame_C02 Page 25 Monday, November 18, 2002 10:40 AM © 2003 by CRC Press LLC