正在加载图片...

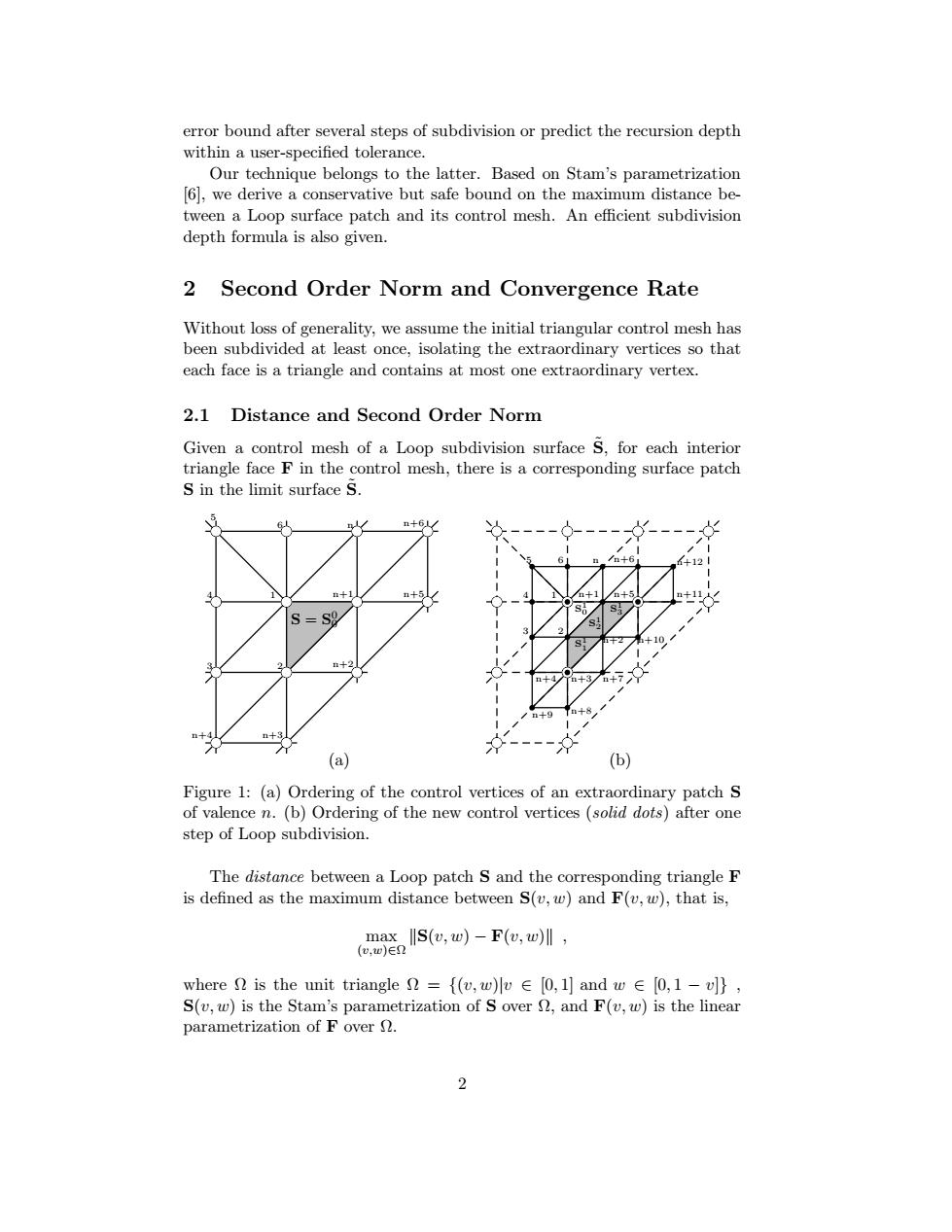

error bound after several steps of subdivision or predict the recursion depth within a user-specified tolerance. Our tochniqc helongs to the latter.Based on Stam's parametrizntion 6):we derive a conservative but safe bound on the maximum distance be- tween a Loop surface patch and its control mesh.An cificient subdivision depth formula is abo given 2 Second Order Norm and Convergence Rate Without loss of grnerality,we nssume the initial trianpular control mesh has been subdivided at least once,isolating the extraordinary vertioes so that cach face is n trinngle and contains at most one ctraordinary vertex. 2.1 Distance and Second Order Norm Given a ooutrol mesh of a Loop subdivision surface S.for each interior trinngle face F in the control mesh,there is a corresponding surface patch snt山e limit surface S. 4中 4中 + (a (b) Figure 1:(a)Ordering of the coutrol vertices of an extraordinary patch S of valence n.(b)Ordering of the new control vertices (solid dots)after one step of Loop subdivision. The distence between a Loop patch S and the corresponding triangle F is definexl as the maximnun distance between S(c,w)and F(v,w),that is, max lIS(t,w)-F(v,w), le.u)cn where is the unit triangle !{(e,w)e [0,1]and w e 0.1), S(e,w)is the Stam's parametrization of S over 52,and F(e,w)is the linear pxarametrization of E over 2error bound after several steps of subdivision or predict the recursion depth within a user-specified tolerance. Our technique belongs to the latter. Based on Stam’s parametrization [6], we derive a conservative but safe bound on the maximum distance between a Loop surface patch and its control mesh. An efficient subdivision depth formula is also given. 2 Second Order Norm and Convergence Rate Without loss of generality, we assume the initial triangular control mesh has been subdivided at least once, isolating the extraordinary vertices so that each face is a triangle and contains at most one extraordinary vertex. 2.1 Distance and Second Order Norm Given a control mesh of a Loop subdivision surface S˜, for each interior triangle face F in the control mesh, there is a corresponding surface patch S in the limit surface S˜. bc bc bc bc bc bc bc bc bc bc bc bc bc 5 6 n n+6 4 1 n+1 n+5 3 2 n+2 n+4 n+3 S = S 0 0 (a) bc bc bc bc bc bc bc bc bc bc bc bc bc b b b b b b b b b b b b b b b b b b b 5 6 n n+6 n+12 4 1 n+1 n+5 n+11 3 2 n+2 n+10 n+4 n+3 n+7 n+9 n+8 S 1 0 S 1 1 S 1 2 S 1 3 (b) Figure 1: (a) Ordering of the control vertices of an extraordinary patch S of valence n. (b) Ordering of the new control vertices (solid dots) after one step of Loop subdivision. The distance between a Loop patch S and the corresponding triangle F is defined as the maximum distance between S(v, w) and F(v, w), that is, max (v,w)∈Ω kS(v, w) − F(v, w)k , where Ω is the unit triangle Ω = {(v, w)|v ∈ [0, 1] and w ∈ [0, 1 − v]} , S(v, w) is the Stam’s parametrization of S over Ω, and F(v, w) is the linear parametrization of F over Ω. 2