正在加载图片...

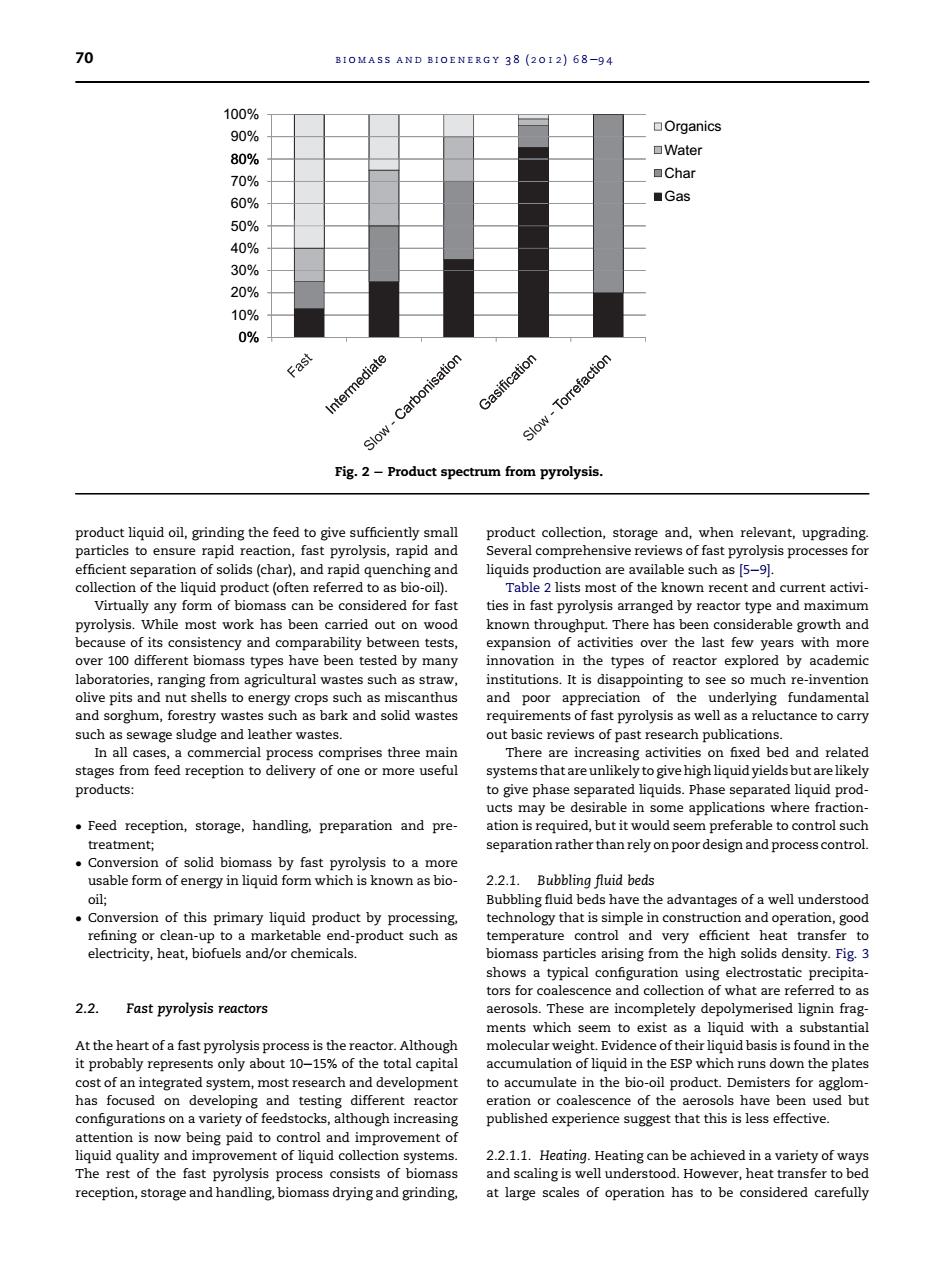

70 BIOMASS AND BIOENERGY 38 (2012)68-94 100% ▣Organics 90% 80% Water 70% ▣Char 60% ■Gas 50% 40% 30% 20% 10% 0% Fast Intermediate Carbonisation Gasification Slow Slow-Torrefaction Fig.2-Product spectrum from pyrolysis. product liquid oil,grinding the feed to give sufficiently small product collection,storage and,when relevant,upgrading. particles to ensure rapid reaction,fast pyrolysis,rapid and Several comprehensive reviews of fast pyrolysis processes for efficient separation of solids(char),and rapid quenching and liquids production are available such as [5-9). collection of the liquid product (often referred to as bio-oil). Table 2 lists most of the known recent and current activi- Virtually any form of biomass can be considered for fast ties in fast pyrolysis arranged by reactor type and maximum pyrolysis.While most work has been carried out on wood known throughput.There has been considerable growth and because of its consistency and comparability between tests, expansion of activities over the last few years with more over 100 different biomass types have been tested by many innovation in the types of reactor explored by academic laboratories,ranging from agricultural wastes such as straw, institutions.It is disappointing to see so much re-invention olive pits and nut shells to energy crops such as miscanthus and poor appreciation of the underlying fundamental and sorghum,forestry wastes such as bark and solid wastes requirements of fast pyrolysis as well as a reluctance to carry such as sewage sludge and leather wastes. out basic reviews of past research publications. In all cases,a commercial process comprises three main There are increasing activities on fixed bed and related stages from feed reception to delivery of one or more useful systems that are unlikely to give high liquid yields but are likely products: to give phase separated liquids.Phase separated liquid prod- ucts may be desirable in some applications where fraction- Feed reception,storage,handling,preparation and pre- ation is required,but it would seem preferable to control such treatment; separation rather than rely on poor design and process control. Conversion of solid biomass by fast pyrolysis to a more usable form of energy in liquid form which is known as bio- 2.2.1.Bubbling fluid beds oil; Bubbling fluid beds have the advantages of a well understood Conversion of this primary liquid product by processing, technology that is simple in construction and operation,good refining or clean-up to a marketable end-product such as temperature control and very efficient heat transfer to electricity,heat,biofuels and/or chemicals. biomass particles arising from the high solids density.Fig.3 shows a typical configuration using electrostatic precipita- tors for coalescence and collection of what are referred to as 2.2. Fast pyrolysis reactors aerosols.These are incompletely depolymerised lignin frag- ments which seem to exist as a liquid with a substantial At the heart of a fast pyrolysis process is the reactor.Although molecular weight.Evidence of their liquid basis is found in the it probably represents only about 10-15%of the total capital accumulation of liquid in the ESP which runs down the plates cost of an integrated system,most research and development to accumulate in the bio-oil product.Demisters for agglom- has focused on developing and testing different reactor eration or coalescence of the aerosols have been used but configurations on a variety of feedstocks,although increasing published experience suggest that this is less effective. attention is now being paid to control and improvement of liquid quality and improvement of liquid collection systems 2.2.1.1.Heating.Heating can be achieved in a variety of ways The rest of the fast pyrolysis process consists of biomass and scaling is well understood.However,heat transfer to bed reception,storage and handling,biomass drying and grinding, at large scales of operation has to be considered carefullyproduct liquid oil, grinding the feed to give sufficiently small particles to ensure rapid reaction, fast pyrolysis, rapid and efficient separation of solids (char), and rapid quenching and collection of the liquid product (often referred to as bio-oil). Virtually any form of biomass can be considered for fast pyrolysis. While most work has been carried out on wood because of its consistency and comparability between tests, over 100 different biomass types have been tested by many laboratories, ranging from agricultural wastes such as straw, olive pits and nut shells to energy crops such as miscanthus and sorghum, forestry wastes such as bark and solid wastes such as sewage sludge and leather wastes. In all cases, a commercial process comprises three main stages from feed reception to delivery of one or more useful products: Feed reception, storage, handling, preparation and pretreatment; Conversion of solid biomass by fast pyrolysis to a more usable form of energy in liquid form which is known as biooil; Conversion of this primary liquid product by processing, refining or clean-up to a marketable end-product such as electricity, heat, biofuels and/or chemicals. 2.2. Fast pyrolysis reactors At the heart of a fast pyrolysis process is the reactor. Although it probably represents only about 10e15% of the total capital cost of an integrated system, most research and development has focused on developing and testing different reactor configurations on a variety of feedstocks, although increasing attention is now being paid to control and improvement of liquid quality and improvement of liquid collection systems. The rest of the fast pyrolysis process consists of biomass reception, storage and handling, biomass drying and grinding, product collection, storage and, when relevant, upgrading. Several comprehensive reviews of fast pyrolysis processes for liquids production are available such as [5e9]. Table 2 lists most of the known recent and current activities in fast pyrolysis arranged by reactor type and maximum known throughput. There has been considerable growth and expansion of activities over the last few years with more innovation in the types of reactor explored by academic institutions. It is disappointing to see so much re-invention and poor appreciation of the underlying fundamental requirements of fast pyrolysis as well as a reluctance to carry out basic reviews of past research publications. There are increasing activities on fixed bed and related systems that are unlikely to give high liquid yields but are likely to give phase separated liquids. Phase separated liquid products may be desirable in some applications where fractionation is required, but it would seem preferable to control such separation rather than rely on poor design and process control. 2.2.1. Bubbling fluid beds Bubbling fluid beds have the advantages of a well understood technology that is simple in construction and operation, good temperature control and very efficient heat transfer to biomass particles arising from the high solids density. Fig. 3 shows a typical configuration using electrostatic precipitators for coalescence and collection of what are referred to as aerosols. These are incompletely depolymerised lignin fragments which seem to exist as a liquid with a substantial molecular weight. Evidence of their liquid basis is found in the accumulation of liquid in the ESP which runs down the plates to accumulate in the bio-oil product. Demisters for agglomeration or coalescence of the aerosols have been used but published experience suggest that this is less effective. 2.2.1.1. Heating. Heating can be achieved in a variety of ways and scaling is well understood. However, heat transfer to bed at large scales of operation has to be considered carefully %08 %09 1 %00 scinagrO retaW 06 % %07 %08 rahC saG %03 %04 50% 0% 10% %02 0% Fig. 2 e Product spectrum from pyrolysis. 70 biomass and bioenergy 38 (2012) 68 e9 4���