正在加载图片...

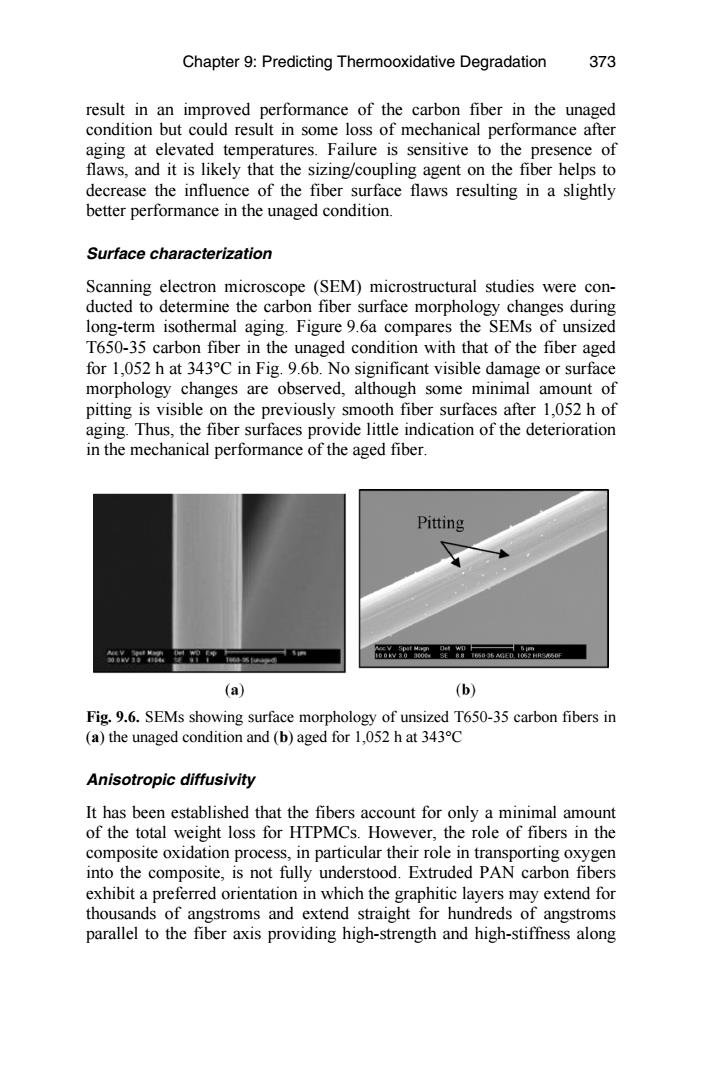

Chapter 9:Predicting Thermooxidative Degradation 373 result in an improved performance of the carbon fiber in the unaged condition but could result in some loss of mechanical performance after aging at elevated temperatures.Failure is sensitive to the presence of flaws,and it is likely that the sizing/coupling agent on the fiber helps to decrease the influence of the fiber surface flaws resulting in a slightly better performance in the unaged condition. Surface characterization Scanning electron microscope (SEM)microstructural studies were con- ducted to determine the carbon fiber surface morphology changes during long-term isothermal aging.Figure 9.6a compares the SEMs of unsized T650-35 carbon fiber in the unaged condition with that of the fiber aged for 1,052 h at 343C in Fig.9.6b.No significant visible damage or surface morphology changes are observed,although some minimal amount of pitting is visible on the previously smooth fiber surfaces after 1,052 h of aging.Thus,the fiber surfaces provide little indication of the deterioration in the mechanical performance of the aged fiber. Pitting Mowitme (a) (b) Fig.9.6.SEMs showing surface morphology of unsized T650-35 carbon fibers in (a)the unaged condition and(b)aged for 1,052 h at 343C Anisotropic diffusivity It has been established that the fibers account for only a minimal amount of the total weight loss for HTPMCs.However,the role of fibers in the composite oxidation process,in particular their role in transporting oxygen into the composite,is not fully understood.Extruded PAN carbon fibers exhibit a preferred orientation in which the graphitic layers may extend for thousands of angstroms and extend straight for hundreds of angstroms parallel to the fiber axis providing high-strength and high-stiffness alongresult in an improved performance of the carbon fiber in the unaged condition but could result in some loss of mechanical performance after aging at elevated temperatures. Failure is sensitive to the presence of flaws, and it is likely that the sizing/coupling agent on the fiber helps to decrease the influence of the fiber surface flaws resulting in a slightly better performance in the unaged condition. Surface characterization Scanning electron microscope (SEM) microstructural studies were conducted to determine the carbon fiber surface morphology changes during long-term isothermal aging. Figure 9.6a compares the SEMs of unsized T650-35 carbon fiber in the unaged condition with that of the fiber aged for 1,052 h at 343°C in Fig. 9.6b. No significant visible damage or surface morphology changes are observed, although some minimal amount of pitting is visible on the previously smooth fiber surfaces after 1,052 h of aging. Thus, the fiber surfaces provide little indication of the deterioration in the mechanical performance of the aged fiber. Fig. 9.6. SEMs showing surface morphology of unsized T650-35 carbon fibers in (a) the unaged condition and (b) aged for 1,052 h at 343°C Anisotropic diffusivity It has been established that the fibers account for only a minimal amount of the total weight loss for HTPMCs. However, the role of fibers in the composite oxidation process, in particular their role in transporting oxygen into the composite, is not fully understood. Extruded PAN carbon fibers exhibit a preferred orientation in which the graphitic layers may extend for thousands of angstroms and extend straight for hundreds of angstroms parallel to the fiber axis providing high-strength and high-stiffness along Chapter 9: Predicting Thermooxidative Degradation 373