正在加载图片...

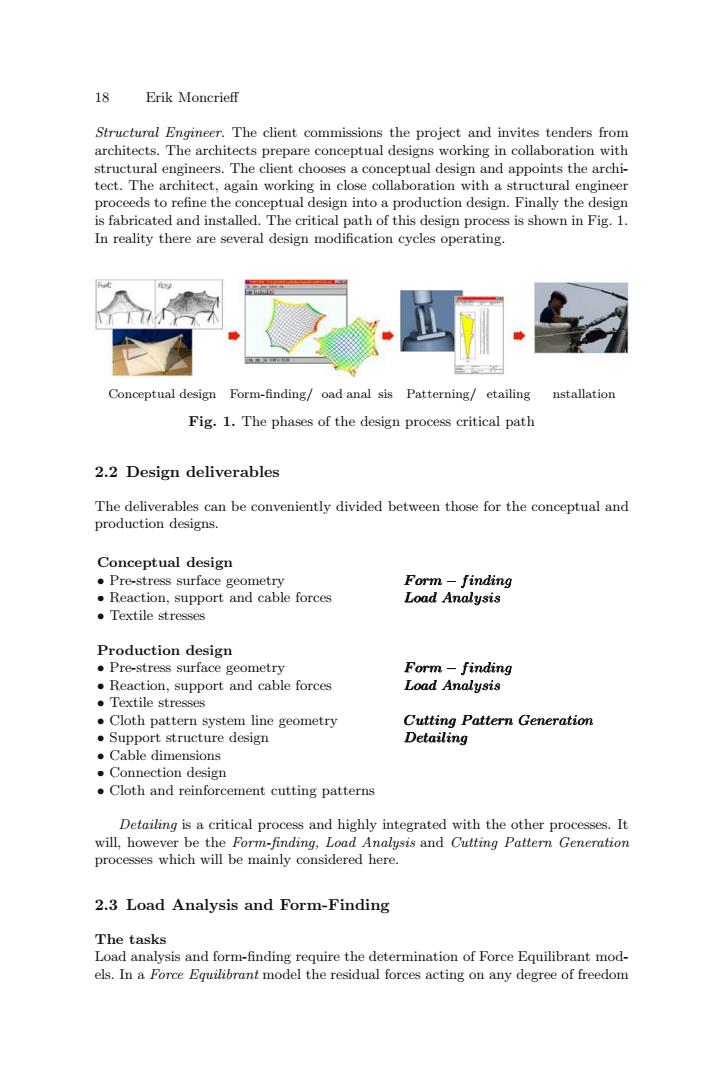

18 Erik Moncrieff Structural Engineer.The client commissions the project and invites tenders from architects.The architects prepare conceptual designs working in collaboration with structural engineers.The client chooses a conceptual design and appoints the archi- tect.The architect,again working in close collaboration with a structural engineer proceeds to refine the conceptual design into a production design.Finally the design is fabricated and installed.The critical path of this design process is shown in Fig.1. In reality there are several design modification cycles operating. Conceptual design Form-finding/oad anal sis Patterning/etailing nstallation Fig.1.The phases of the design process critical path 2.2 Design deliverables The deliverables can be conveniently divided between those for the conceptual and production designs. Conceptual design Pre-stress surface geometry Form-finding Reaction,support and cable forces Load Analysis ●Textile stresses Production design Pre-stress surface geometry Form-finding Reaction,support and cable forces Load Analysis ●Textile stresses Cloth pattern system line geometry Cutting Pattern Generation Support structure design Detailing ●Cable dimensions ·Connection design Cloth and reinforcement cutting patterns Detailing is a critical process and highly integrated with the other processes.It will,however be the Form-finding,Load Analysis and Cutting Pattern Generation processes which will be mainly considered here. 2.3 Load Analysis and Form-Finding The tasks Load analysis and form-finding require the determination of Force Equilibrant mod- els.In a Force Equilibrant model the residual forces acting on any degree of freedom18 Erik Moncrieff Structural Engineer. The client commissions the project and invites tenders from architects. The architects prepare conceptual designs working in collaboration with structural engineers. The client chooses a conceptual design and appoints the architect. The architect, again working in close collaboration with a structural engineer proceeds to refine the conceptual design into a production design. Finally the design is fabricated and installed. The critical path of this design process is shown in Fig. 1. In reality there are several design modification cycles operating. Conceptual design Form-finding/ oad anal sis Patterning/ etailing nstallation Fig. 1. The phases of the design process critical path 2.2 Design deliverables The deliverables can be conveniently divided between those for the conceptual and production designs. Conceptual design • Pre-stress surface geometry F orm F − f inding f d ining • Reaction, support and cable forces Load Analysis Load Analysis Load Analysis oad Analysis nalysis • Textile stresses Production design • Pre-stress surface geometry F orm F − f inding f d ining • Reaction, support and cable forces Load Analysis Load Analysis Load Analysis oad Analysis • Textile stresses • Cloth pattern system line geometry Cutting P attern Generation Cutting P attern Generation C Gutting P attern Generation utting P attern Generation • Support structure design Detailing D etailing etailing • Cable dimensions • Connection design • Cloth and reinforcement cutting patterns Detailing is a critical process and highly integrated with the other processes. It will, however be the Form-finding, Load Analysis and Cutting Pattern Generation processes which will be mainly considered here. 2.3 Load Analysis and Form-Finding The tasks Load analysis and form-finding require the determination of Force Equilibrant models. In a Force Equilibrant model the residual forces acting on any degree of freedom