正在加载图片...

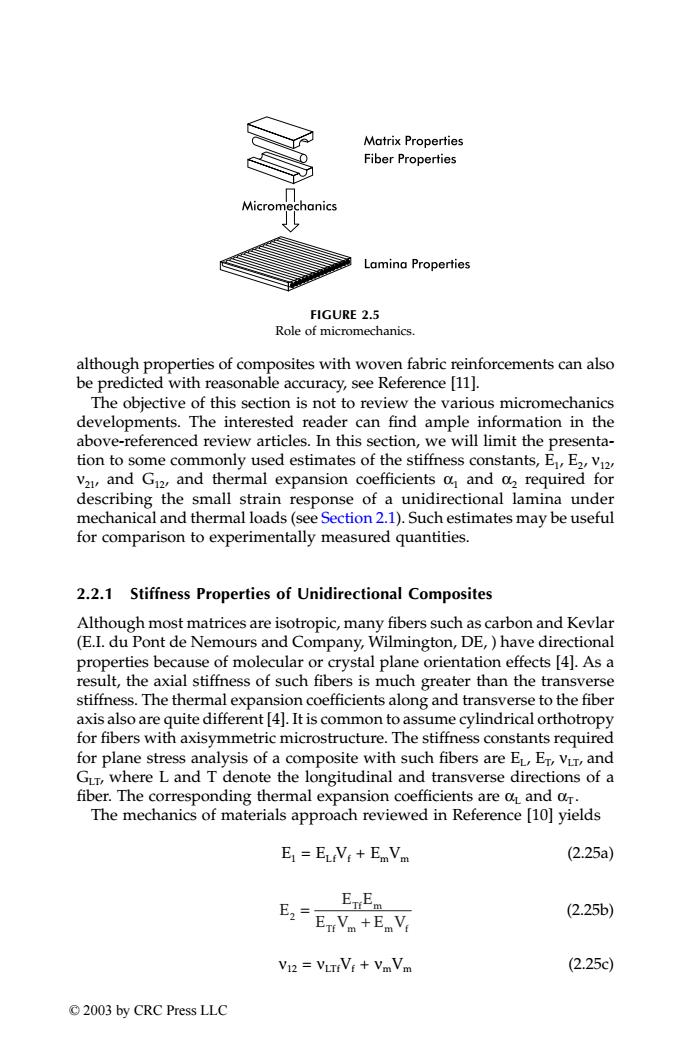

Matrix Properties Fiber Properties Micromechanics Lamina Properties FIGURE 2.5 Role of micromechanics. although properties of composites with woven fabric reinforcements can also be predicted with reasonable accuracy,see Reference [11]. The objective of this section is not to review the various micromechanics developments.The interested reader can find ample information in the above-referenced review articles.In this section,we will limit the presenta- tion to some commonly used estimates of the stiffness constants,E,E2,Viz, va,and Gu2,and thermal expansion coefficients a and a required for describing the small strain response of a unidirectional lamina under mechanical and thermal loads(see Section 2.1).Such estimates may be useful for comparison to experimentally measured quantities. 2.2.1 Stiffness Properties of Unidirectional Composites Although most matrices are isotropic,many fibers such as carbon and Kevlar (E.I.du Pont de Nemours and Company,Wilmington,DE,)have directional properties because of molecular or crystal plane orientation effects [4].As a result,the axial stiffness of such fibers is much greater than the transverse stiffness.The thermal expansion coefficients along and transverse to the fiber axis also are quite different [4].It is common to assume cylindrical orthotropy for fibers with axisymmetric microstructure.The stiffness constants required for plane stress analysis of a composite with such fibers are EL,Er,Vr,and GLr,where L and T denote the longitudinal and transverse directions of a fiber.The corresponding thermal expansion coefficients are o and ar. The mechanics of materials approach reviewed in Reference [10]yields E=ELiVi+EmVm (2.25a) EnEm E,FEV。+EnV (2.25b) V12 VLTIVi Vm Vm (2.25c) ©2003 by CRC Press LLCalthough properties of composites with woven fabric reinforcements can also be predicted with reasonable accuracy, see Reference [11]. The objective of this section is not to review the various micromechanics developments. The interested reader can find ample information in the above-referenced review articles. In this section, we will limit the presentation to some commonly used estimates of the stiffness constants, E1, E2, ν12, ν21, and G12, and thermal expansion coefficients α1 and α2 required for describing the small strain response of a unidirectional lamina under mechanical and thermal loads (see Section 2.1). Such estimates may be useful for comparison to experimentally measured quantities. 2.2.1 Stiffness Properties of Unidirectional Composites Although most matrices are isotropic, many fibers such as carbon and Kevlar (E.I. du Pont de Nemours and Company, Wilmington, DE, ) have directional properties because of molecular or crystal plane orientation effects [4]. As a result, the axial stiffness of such fibers is much greater than the transverse stiffness. The thermal expansion coefficients along and transverse to the fiber axis also are quite different [4]. It is common to assume cylindrical orthotropy for fibers with axisymmetric microstructure. The stiffness constants required for plane stress analysis of a composite with such fibers are EL, ET, νLT, and GLT, where L and T denote the longitudinal and transverse directions of a fiber. The corresponding thermal expansion coefficients are αL and αT. The mechanics of materials approach reviewed in Reference [10] yields E1 = ELfVf + EmVm (2.25a) (2.25b) ν12 = νLTfVf + νmVm (2.25c) FIGURE 2.5 Role of micromechanics. E E E EV EV Tf m Tf m m f 2 = + TX001_ch02_Frame Page 18 Saturday, September 21, 2002 4:48 AM © 2003 by CRC Press LLC