正在加载图片...

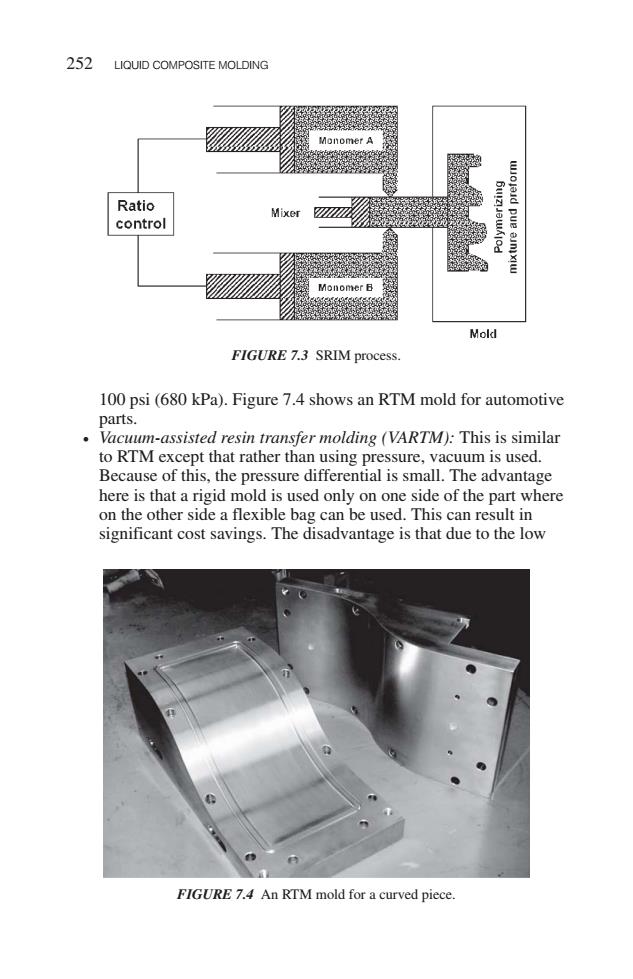

252 LIQUID COMPOSITE MOLDING Monomer A Ratio Mixer control 84 SuizJawXlod Monomer B Mold FIGURE 7.3 SRIM process. 100 psi(680 kPa).Figure 7.4 shows an RTM mold for automotive parts. Vacuum-assisted resin transfer molding (VARTM):This is similar to RTM except that rather than using pressure,vacuum is used. Because of this,the pressure differential is small.The advantage here is that a rigid mold is used only on one side of the part where on the other side a flexible bag can be used.This can result in significant cost savings.The disadvantage is that due to the low FIGURE 7.4 An RTM mold for a curved piece.100 psi (680 kPa). Figure 7.4 shows an RTM mold for automotive parts. • Vacuum-assisted resin transfer molding (VARTM): This is similar to RTM except that rather than using pressure, vacuum is used. Because of this, the pressure differential is small. The advantage here is that a rigid mold is used only on one side of the part where on the other side a flexible bag can be used. This can result in significant cost savings. The disadvantage is that due to the low 252 LIQUID COMPOSITE MOLDING FIGURE 7.3 SRIM process. FIGURE 7.4 An RTM mold for a curved piece