正在加载图片...

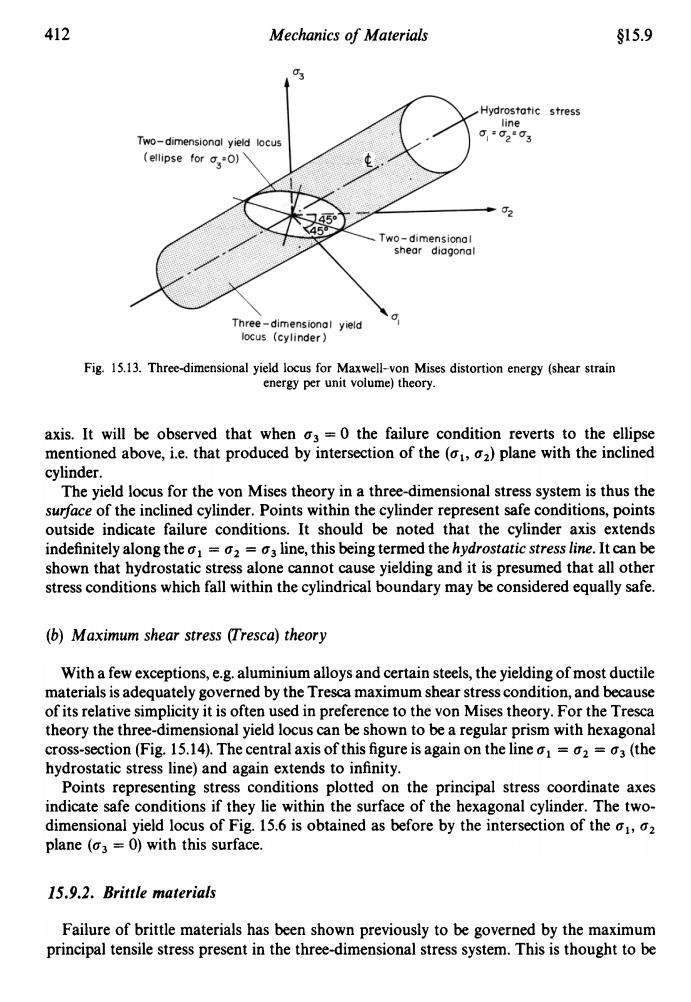

412 Mechanics of Materials S15.9 6 Hydrostatic stress line Two-dimensional yield locus 可02"03 (ellipse for oO) 450 ◆2 45 Two-dimensional shear diagonal Three-dimensional yield locus(cylinder】 Fig.15.13.Three-dimensional yield locus for Maxwell-von Mises distortion energy (shear strain energy per unit volume)theory. axis.It will be observed that when o3=0 the failure condition reverts to the ellipse mentioned above,i.e.that produced by intersection of the (1,2)plane with the inclined cylinder. The yield locus for the von Mises theory in a three-dimensional stress system is thus the surface of the inclined cylinder.Points within the cylinder represent safe conditions,points outside indicate failure conditions.It should be noted that the cylinder axis extends indefinitely along thea=o2=o3 line,this being termed the hydrostatic stress line.It can be shown that hydrostatic stress alone cannot cause yielding and it is presumed that all other stress conditions which fall within the cylindrical boundary may be considered equally safe. (b)Maximum shear stress (Tresca)theory With a few exceptions,e.g.aluminium alloys and certain steels,the yielding of most ductile materials is adequately governed by the Tresca maximum shear stress condition,and because of its relative simplicity it is often used in preference to the von Mises theory.For the Tresca theory the three-dimensional yield locus can be shown to be a regular prism with hexagonal cross-section(Fig.15.14).The central axis of this figure is again on the line=02=03(the hydrostatic stress line)and again extends to infinity. Points representing stress conditions plotted on the principal stress coordinate axes indicate safe conditions if they lie within the surface of the hexagonal cylinder.The two- dimensional yield locus of Fig.15.6 is obtained as before by the intersection of the 1,2 plane (o3 =0)with this surface. 15.9.2.Brittle materials Failure of brittle materials has been shown previously to be governed by the maximum principal tensile stress present in the three-dimensional stress system.This is thought to be412 Mechanics of Materials §15.9 Fig. 15.13. Three-dimensional yield locus for Maxwell-von Mises distortion energy (shear strain energy per unit volume) theory. axis. It will be observed that when 0'3 = O the failure condition reverts to the ellipse mentioned above, i.e. that produced by intersection of the (0'1'0'2) plane with the inclined cylinder. The yield locus for the von Mises theory in a three-dimensional stress system is thus the surface of the inclined cylinder. Points within the cylinder represent safe conditions, points outside indicate failure conditions. It should be noted that the cylinder axis extends indefinitely along the 0' 1 = 0' 2 = 0' 3line, this being termed the hydrostatic stress line. It can be shown that hydrostatic stress alone cannot cause yielding and it is presumed that all other stress conditions which fall within the cylindrical boundary may be considered equally safe. (b) Maximum shear stress (Tresca) theory With a few exceptions, e.g. aluminium alloys and certain steels, the yielding of most ductile materials is adequately governed by the Tresca maximum shear stress condition, and because ofits relative simplicity it is often used in preference to the von Mises theory. For the Tresca theory the three-dimensional yield locus can be shown to be a regular prism with hexagonal cross-section (Fig. 15.14). The central axis of this figure is again on the line 0"1 = 0"2 = 0"3 (the hydrostatic stress line) and again extends to infinity. Points representing stress conditions plotted on the principal stress coordinate axes indicate safe conditions if they lie within the surface of the hexagonal cylinder. The twodimensional yield locus of Fig. 15.6 is obtained as before by the intersection of the 0"1' 0"2 plane (0"3 = 0) with this surface. 15.9.2. Brittle materials Failure of brittle materials has been shown previously to be governed by the maximum principal tensile stress present in the three-dimensional stress system. This is thought to be