正在加载图片...

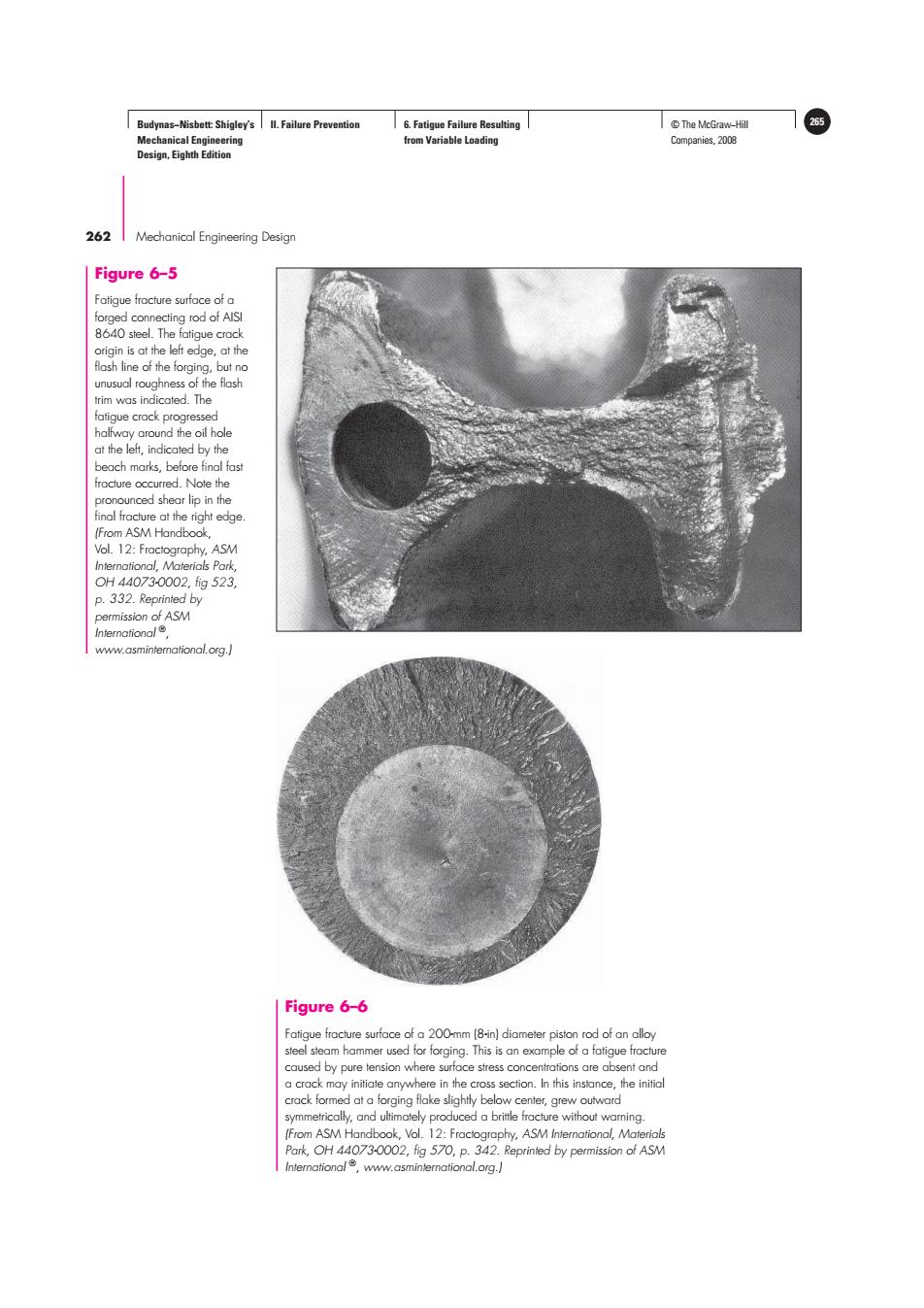

Budynas-Nisbett:Shigley's ll.Failure Prevention 6.Fatigue Failure Resulting T©The McGraw-Hil 265 Mechanical Engineering from Variable Loading Companies,2008 Design,Eighth Edition 262 Mechanical Engineering Design Figure 6-5 Fatique fracture surface of a forged connecting rod of AlSI 8640 steel.The fatigue crack origin is at the left edge,at the flash line of the forging,but no unusual roughness of the flash trim was indicated.The fatigue crack progressed halfway around the oil hole at the left,indicated by the beach marks,before final fast racture occurred.Note the pronounced shear lip in the final fracture at the right edge. (From ASM Handbook, Vol.12:Fractography,ASM International,Materials Park, OH440730002,fig523, p.332.Reprinted by permission of ASM International www.asminterational.org.) Figure 6-6 Fatigue fracture surface of a 200-mm (8-in)diameter piston rod of an alloy steel steam hammer used for forging.This is an example ofa fatigue fracture caused by pure tension where surfoce stress concentrations are absent and a crack may initiate anywhere in the cross section.In this instance,the initial crack formed at a forging flake slightly below center,grew outward symmetrically,and ultimately produced a brittle fracture without warning. (From ASM Handbook,Vol.12:Fractography,ASM Interational,Materials Park,OH 44073-0002,fig 570,p.342.Reprinted by permission of ASM International,www.asminternational.org.)Budynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition II. Failure Prevention 6. Fatigue Failure Resulting from Variable Loading © The McGraw−Hill 265 Companies, 2008 262 Mechanical Engineering Design Figure 6–5 Fatigue fracture surface of a forged connecting rod of AISI 8640 steel. The fatigue crack origin is at the left edge, at the flash line of the forging, but no unusual roughness of the flash trim was indicated. The fatigue crack progressed halfway around the oil hole at the left, indicated by the beach marks, before final fast fracture occurred. Note the pronounced shear lip in the final fracture at the right edge. (From ASM Handbook, Vol. 12: Fractography, ASM International, Materials Park, OH 44073-0002, fig 523, p. 332. Reprinted by permission of ASM International ®, www.asminternational.org.) Figure 6–6 Fatigue fracture surface of a 200-mm (8-in) diameter piston rod of an alloy steel steam hammer used for forging. This is an example of a fatigue fracture caused by pure tension where surface stress concentrations are absent and a crack may initiate anywhere in the cross section. In this instance, the initial crack formed at a forging flake slightly below center, grew outward symmetrically, and ultimately produced a brittle fracture without warning. (From ASM Handbook, Vol. 12: Fractography, ASM International, Materials Park, OH 44073-0002, fig 570, p. 342. Reprinted by permission of ASM International ®, www.asminternational.org.)