正在加载图片...

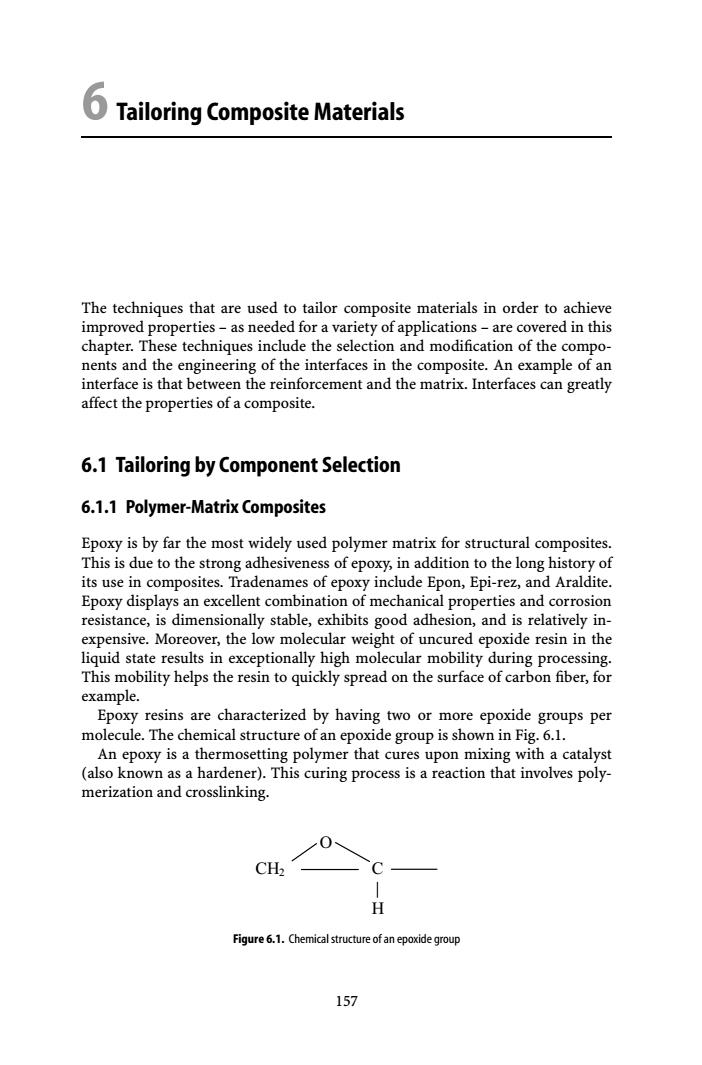

6 Tailoring Composite Materials The techniques that are used to tailor composite materials in order to achieve improved properties-as needed for a variety of applications-are covered in this chapter.These techniques include the selection and modification of the compo- nents and the engineering of the interfaces in the composite.An example of an interface is that between the reinforcement and the matrix.Interfaces can greatly affect the properties of a composite. 6.1 Tailoring by Component Selection 6.1.1 Polymer-Matrix Composites Epoxy is by far the most widely used polymer matrix for structural composites. This is due to the strong adhesiveness of epoxy,in addition to the long history of its use in composites.Tradenames of epoxy include Epon,Epi-rez,and Araldite Epoxy displays an excellent combination of mechanical properties and corrosion resistance,is dimensionally stable,exhibits good adhesion,and is relatively in- expensive.Moreover,the low molecular weight of uncured epoxide resin in the liquid state results in exceptionally high molecular mobility during processing. This mobility helps the resin to quickly spread on the surface of carbon fiber,for example. Epoxy resins are characterized by having two or more epoxide groups per molecule.The chemical structure of an epoxide group is shown in Fig.6.1. An epoxy is a thermosetting polymer that cures upon mixing with a catalyst (also known as a hardener).This curing process is a reaction that involves poly- merization and crosslinking. H Figure 6.1.Chemical structure of an epoxide group 1576 Tailoring Composite Materials The techniques that are used to tailor composite materials in order to achieve improved properties – as needed for a variety of applications – are covered in this chapter. These techniques include the selection and modification of the components and the engineering of the interfaces in the composite. An example of an interface is that between the reinforcement and the matrix. Interfaces can greatly affect the properties of a composite. 6.1 Tailoring by Component Selection 6.1.1 Polymer-Matrix Composites Epoxy is by far the most widely used polymer matrix for structural composites. This is due to the strong adhesiveness of epoxy, in addition to the long history of its use in composites. Tradenames of epoxy include Epon, Epi-rez, and Araldite. Epoxy displays an excellent combination of mechanical properties and corrosion resistance, is dimensionally stable, exhibits good adhesion, and is relatively inexpensive. Moreover, the low molecular weight of uncured epoxide resin in the liquid state results in exceptionally high molecular mobility during processing. This mobility helps the resin to quickly spread on the surface of carbon fiber, for example. Epoxy resins are characterized by having two or more epoxide groups per molecule. The chemical structure of an epoxide group is shown in Fig. 6.1. An epoxy is a thermosetting polymer that cures upon mixing with a catalyst (also known as a hardener). This curing process is a reaction that involves polymerization and crosslinking. O CH2 C | H Figure 6.1. Chemical structure of an epoxide group 157