正在加载图片...

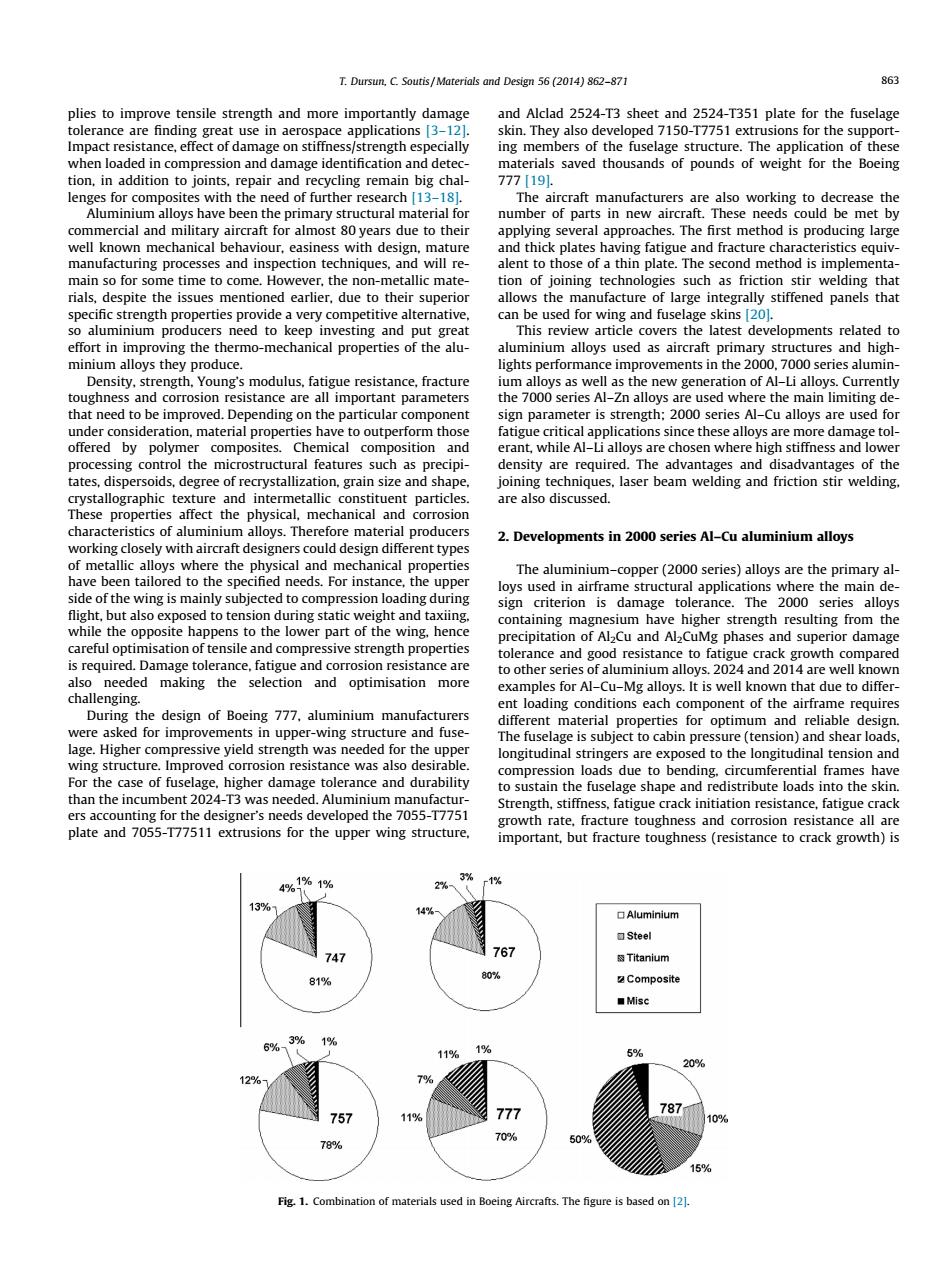

T.Dursun.C.Soutis /Materials and Design 56(2014)862-871 863 plies to improve tensile strength and more importantly damage and Alclad 2524-T3 sheet and 2524-T351 plate for the fuselage tolerance are finding great use in aerospace applications [3-12]. skin.They also developed 7150-T7751 extrusions for the support- Impact resistance,effect of damage on stiffness/strength especially ing members of the fuselage structure.The application of these when loaded in compression and damage identification and detec- materials saved thousands of pounds of weight for the Boeing tion,in addition to joints,repair and recycling remain big chal- 777[191. lenges for composites with the need of further research [13-18] The aircraft manufacturers are also working to decrease the Aluminium alloys have been the primary structural material for number of parts in new aircraft.These needs could be met by commercial and military aircraft for almost 80 years due to their applying several approaches.The first method is producing large well known mechanical behaviour,easiness with design,mature and thick plates having fatigue and fracture characteristics equiv- manufacturing processes and inspection techniques,and will re- alent to those of a thin plate.The second method is implementa- main so for some time to come.However,the non-metallic mate- tion of joining technologies such as friction stir welding that rials,despite the issues mentioned earlier,due to their superior allows the manufacture of large integrally stiffened panels that specific strength properties provide a very competitive alternative, can be used for wing and fuselage skins [201. so aluminium producers need to keep investing and put great This review article covers the latest developments related to effort in improving the thermo-mechanical properties of the alu- aluminium alloys used as aircraft primary structures and high- minium alloys they produce. lights performance improvements in the 2000,7000 series alumin- Density.strength,Young's modulus,fatigue resistance,fracture ium alloys as well as the new generation of Al-Li alloys.Currently toughness and corrosion resistance are all important parameters the 7000 series Al-Zn alloys are used where the main limiting de- that need to be improved.Depending on the particular component sign parameter is strength:2000 series Al-Cu alloys are used for under consideration,material properties have to outperform those fatigue critical applications since these alloys are more damage tol- offered by polymer composites.Chemical composition and erant,while Al-Li alloys are chosen where high stiffness and lower processing control the microstructural features such as precipi- density are required.The advantages and disadvantages of the tates,dispersoids,degree of recrystallization,grain size and shape, joining techniques,laser beam welding and friction stir welding. crystallographic texture and intermetallic constituent particles. are also discussed. These properties affect the physical,mechanical and corrosion characteristics of aluminium alloys.Therefore material producers 2.Developments in 2000 series Al-Cu aluminium alloys working closely with aircraft designers could design different types of metallic alloys where the physical and mechanical properties The aluminium-copper(2000 series)alloys are the primary al- have been tailored to the specified needs.For instance,the upper loys used in airframe structural applications where the main de- side of the wing is mainly subjected to compression loading during sign criterion is damage tolerance.The 2000 series alloys flight,but also exposed to tension during static weight and taxiing. containing magnesium have higher strength resulting from the while the opposite happens to the lower part of the wing.hence precipitation of Al2Cu and AlzCuMg phases and superior damage careful optimisation of tensile and compressive strength properties tolerance and good resistance to fatigue crack growth compared is required.Damage tolerance,fatigue and corrosion resistance are to other series of aluminium alloys.2024 and 2014 are well known also needed making the selection and optimisation more examples for Al-Cu-Mg alloys.It is well known that due to differ- challenging. ent loading conditions each component of the airframe requires During the design of Boeing 777,aluminium manufacturers different material properties for optimum and reliable design. were asked for improvements in upper-wing structure and fuse- The fuselage is subject to cabin pressure (tension)and shear loads. lage.Higher compressive yield strength was needed for the upper longitudinal stringers are exposed to the longitudinal tension and wing structure.Improved corrosion resistance was also desirable. compression loads due to bending.circumferential frames have For the case of fuselage,higher damage tolerance and durability to sustain the fuselage shape and redistribute loads into the skin. than the incumbent 2024-T3 was needed.Aluminium manufactur- Strength,stiffness,fatigue crack initiation resistance,fatigue crack ers accounting for the designer's needs developed the 7055-T7751 growth rate,fracture toughness and corrosion resistance all are plate and 7055-177511 extrusions for the upper wing structure, important,but fracture toughness(resistance to crack growth)is 49%1%1% 5% 1% 13% 14% Aluminium Steel 747 767 Titanium 81% 80% Composite ■Misc 6% 3% 1% 11% 1% 5% 20% 12% % 777 T87 757 11% 10% 70% 78% 50% 15% Fig.1.Combination of materials used in Boeing Aircrafts.The figure is based on [2].plies to improve tensile strength and more importantly damage tolerance are finding great use in aerospace applications [3–12]. Impact resistance, effect of damage on stiffness/strength especially when loaded in compression and damage identification and detection, in addition to joints, repair and recycling remain big challenges for composites with the need of further research [13–18]. Aluminium alloys have been the primary structural material for commercial and military aircraft for almost 80 years due to their well known mechanical behaviour, easiness with design, mature manufacturing processes and inspection techniques, and will remain so for some time to come. However, the non-metallic materials, despite the issues mentioned earlier, due to their superior specific strength properties provide a very competitive alternative, so aluminium producers need to keep investing and put great effort in improving the thermo-mechanical properties of the aluminium alloys they produce. Density, strength, Young’s modulus, fatigue resistance, fracture toughness and corrosion resistance are all important parameters that need to be improved. Depending on the particular component under consideration, material properties have to outperform those offered by polymer composites. Chemical composition and processing control the microstructural features such as precipitates, dispersoids, degree of recrystallization, grain size and shape, crystallographic texture and intermetallic constituent particles. These properties affect the physical, mechanical and corrosion characteristics of aluminium alloys. Therefore material producers working closely with aircraft designers could design different types of metallic alloys where the physical and mechanical properties have been tailored to the specified needs. For instance, the upper side of the wing is mainly subjected to compression loading during flight, but also exposed to tension during static weight and taxiing, while the opposite happens to the lower part of the wing, hence careful optimisation of tensile and compressive strength properties is required. Damage tolerance, fatigue and corrosion resistance are also needed making the selection and optimisation more challenging. During the design of Boeing 777, aluminium manufacturers were asked for improvements in upper-wing structure and fuselage. Higher compressive yield strength was needed for the upper wing structure. Improved corrosion resistance was also desirable. For the case of fuselage, higher damage tolerance and durability than the incumbent 2024-T3 was needed. Aluminium manufacturers accounting for the designer’s needs developed the 7055-T7751 plate and 7055-T77511 extrusions for the upper wing structure, and Alclad 2524-T3 sheet and 2524-T351 plate for the fuselage skin. They also developed 7150-T7751 extrusions for the supporting members of the fuselage structure. The application of these materials saved thousands of pounds of weight for the Boeing 777 [19]. The aircraft manufacturers are also working to decrease the number of parts in new aircraft. These needs could be met by applying several approaches. The first method is producing large and thick plates having fatigue and fracture characteristics equivalent to those of a thin plate. The second method is implementation of joining technologies such as friction stir welding that allows the manufacture of large integrally stiffened panels that can be used for wing and fuselage skins [20]. This review article covers the latest developments related to aluminium alloys used as aircraft primary structures and highlights performance improvements in the 2000, 7000 series aluminium alloys as well as the new generation of Al–Li alloys. Currently the 7000 series Al–Zn alloys are used where the main limiting design parameter is strength; 2000 series Al–Cu alloys are used for fatigue critical applications since these alloys are more damage tolerant, while Al–Li alloys are chosen where high stiffness and lower density are required. The advantages and disadvantages of the joining techniques, laser beam welding and friction stir welding, are also discussed. 2. Developments in 2000 series Al–Cu aluminium alloys The aluminium–copper (2000 series) alloys are the primary alloys used in airframe structural applications where the main design criterion is damage tolerance. The 2000 series alloys containing magnesium have higher strength resulting from the precipitation of Al2Cu and Al2CuMg phases and superior damage tolerance and good resistance to fatigue crack growth compared to other series of aluminium alloys. 2024 and 2014 are well known examples for Al–Cu–Mg alloys. It is well known that due to different loading conditions each component of the airframe requires different material properties for optimum and reliable design. The fuselage is subject to cabin pressure (tension) and shear loads, longitudinal stringers are exposed to the longitudinal tension and compression loads due to bending, circumferential frames have to sustain the fuselage shape and redistribute loads into the skin. Strength, stiffness, fatigue crack initiation resistance, fatigue crack growth rate, fracture toughness and corrosion resistance all are important, but fracture toughness (resistance to crack growth) is Fig. 1. Combination of materials used in Boeing Aircrafts. The figure is based on [2]. T. Dursun, C. Soutis / Materials and Design 56 (2014) 862–871 863