正在加载图片...

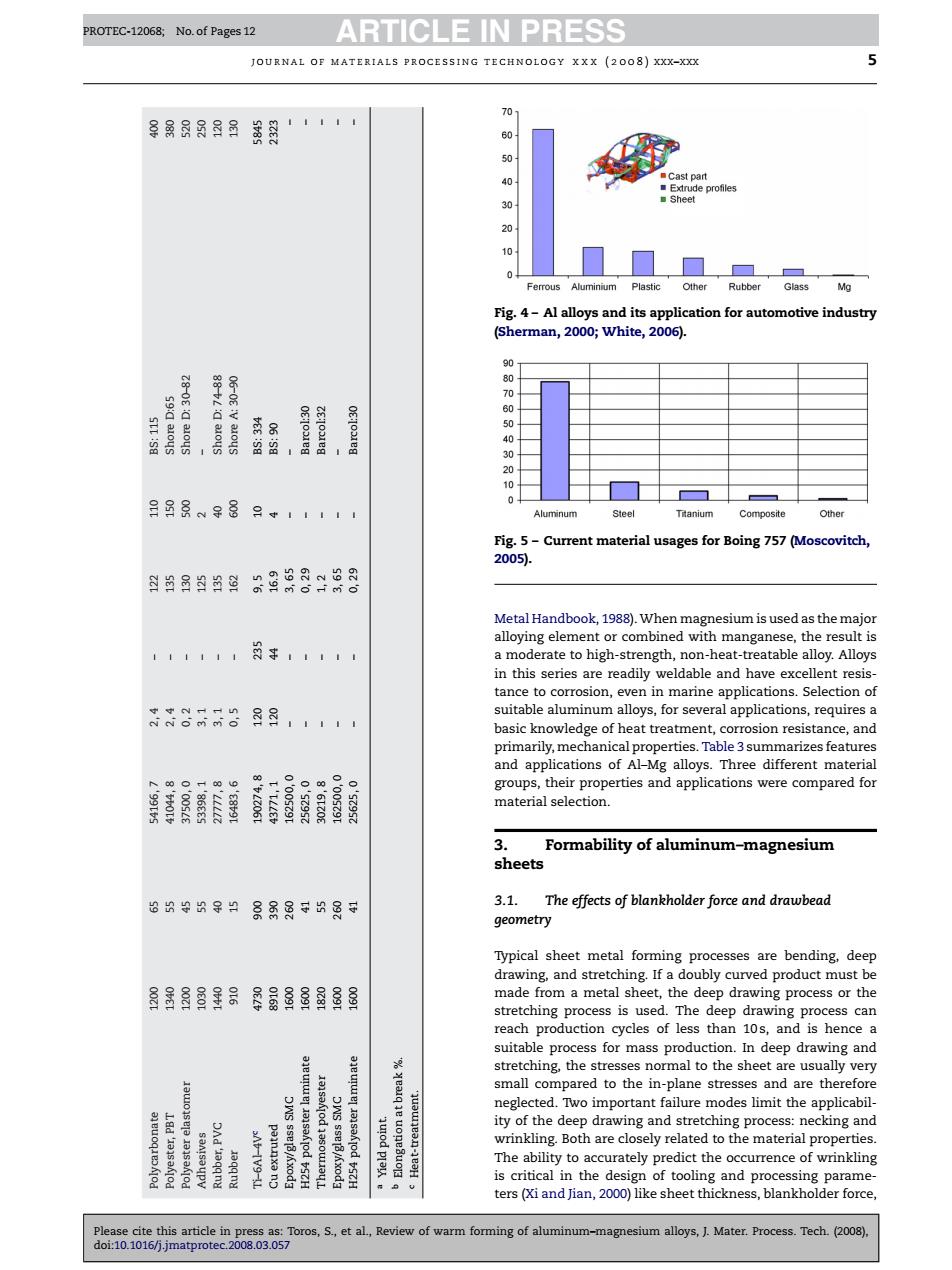

PROTEC-12068.No.of Pages 12 ARTICLE IN PRESS JOURNAL OF MATERIALS PROCESSING TECHNOLOGY XXX (2008)XXX-X 景属8另88宝8:1 Fig.4-Alalloys and its application for automotive industry (Sherman,2000;White,2006). 0%5-cunetmtealuagesfcBoing7S7AMosconih 的始88始兽片3设8:总8 Metal Handbook.1988).When magnesium is used as the maio ength,no y.Aloy tance even in marine applications.Selection of g所g8 alloys,for several primarily,mechanical properties.Table 3summarizes feature 首程窗 Formability of aluminum-magnesium sheets 8份好份导9景尽员于的员可 The effects of blankholder force and drawbead 8星品品品品品 made from a metal sheet,the deep drawing process or the suitable pre mal to the sheet are us ted.Two important failure modes limit the applicabil of thec p dra wing and s tretching process:necking and to accurately predict the occurrence of wrinkling is critical 8i5pd5,ao,stl,ioawofvamfomingodahmnum-mgneumaoys1ateocsTdhpocgl Please cite this article in press as: Toros, S., et al., Review of warm forming of aluminum–magnesium alloys, J. Mater. Process. Tech. (2008), doi:10.1016/j.jmatprotec.2008.03.057 PROTEC-12068; No. of Pages 12 ARTICLE IN PRESS journal of materials processing technology xxx (2008) xxx–xxx 5 Polycarbonate 1200 65 54166, 7 2, 4 – 122 110 BS: 115 400 Polyester, PBT 1340 55 41044, 8 2, 4 – 135 150 Shore D:65 380 Polyester elastomer 1200 45 37500, 0 0, 2 – 130 500 Shore D: 30–82 520 Adhesives 1030 55 53398, 1 3, 1 – 125 2 – 250 Rubber, PVC 1440 40 27777, 8 3, 1 – 135 40 Shore D: 74–88 120 Rubber 910 15 16483, 6 0, 5 – 162 600 Shore A: 30–90 130 Ti–6Al–4Vc 4730 900 190274, 8 120 235 9, 5 10 BS: 334 5845 Cu extruted 8910 390 43771, 1 120 44 16.9 4 BS: 90 2323 Epoxy/glass SMC 1600 260 162500, 0 – – 3, 65 – – – H254 polyester laminate 1600 41 25625, 0 – – 0, 29 – Barcol:30 – Thermoset polyester 1820 55 30219, 8 – – 1, 2 – Barcol:32 – Epoxy/glass SMC 1600 260 162500, 0 – – 3, 65 – – – H254 polyester laminate 1600 41 25625, 0 – – 0, 29 – Barcol:30 – a Yield point. b Elongation at break %. c Heat-treatment. Fig. 4 – Al alloys and its application for automotive industry (Sherman, 2000; White, 2006). Fig. 5 – Current material usages for Boing 757 (Moscovitch, 2005). Metal Handbook, 1988). When magnesium is used as the major alloying element or combined with manganese, the result is a moderate to high-strength, non-heat-treatable alloy. Alloys in this series are readily weldable and have excellent resistance to corrosion, even in marine applications. Selection of suitable aluminum alloys, for several applications, requires a basic knowledge of heat treatment, corrosion resistance, and primarily, mechanical properties. Table 3 summarizes features and applications of Al–Mg alloys. Three different material groups, their properties and applications were compared for material selection. 3. Formability of aluminum–magnesium sheets 3.1. The effects of blankholder force and drawbead geometry Typical sheet metal forming processes are bending, deep drawing, and stretching. If a doubly curved product must be made from a metal sheet, the deep drawing process or the stretching process is used. The deep drawing process can reach production cycles of less than 10 s, and is hence a suitable process for mass production. In deep drawing and stretching, the stresses normal to the sheet are usually very small compared to the in-plane stresses and are therefore neglected. Two important failure modes limit the applicability of the deep drawing and stretching process: necking and wrinkling. Both are closely related to the material properties. The ability to accurately predict the occurrence of wrinkling is critical in the design of tooling and processing parameters (Xi and Jian, 2000) like sheet thickness, blankholder force