正在加载图片...

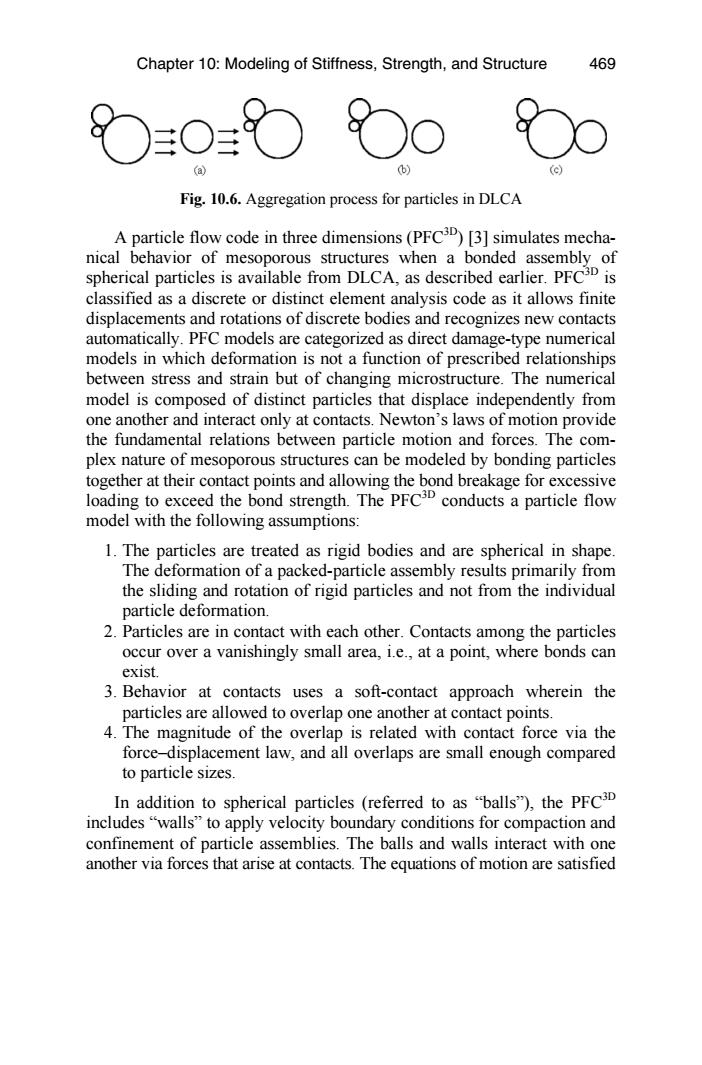

Chapter 10:Modeling of Stiffness,Strength,and Structure 469 (e) Fig.10.6.Aggregation process for particles in DLCA A particle flow code in three dimensions(PFC3)[3]simulates mecha- nical behavior of mesoporous structures when a bonded assembly of spherical particles is available from DLCA,as described earlier.PFC3D is classified as a discrete or distinct element analysis code as it allows finite displacements and rotations of discrete bodies and recognizes new contacts automatically.PFC models are categorized as direct damage-type numerical models in which deformation is not a function of prescribed relationships between stress and strain but of changing microstructure.The numerical model is composed of distinct particles that displace independently from one another and interact only at contacts.Newton's laws of motion provide the fundamental relations between particle motion and forces.The com- plex nature of mesoporous structures can be modeled by bonding particles together at their contact points and allowing the bond breakage for excessive loading to exceed the bond strength.The PFC3 conducts a particle flow model with the following assumptions: 1.The particles are treated as rigid bodies and are spherical in shape. The deformation of a packed-particle assembly results primarily from the sliding and rotation of rigid particles and not from the individual particle deformation. 2.Particles are in contact with each other.Contacts among the particles occur over a vanishingly small area,i.e.,at a point,where bonds can exist. 3.Behavior at contacts uses a soft-contact approach wherein the particles are allowed to overlap one another at contact points. 4.The magnitude of the overlap is related with contact force via the force-displacement law,and all overlaps are small enough compared to particle sizes. In addition to spherical particles (referred to as "balls"),the PFC3D includes"walls"to apply velocity boundary conditions for compaction and confinement of particle assemblies.The balls and walls interact with one another via forces that arise at contacts.The equations of motion are satisfiedFig. 10.6. Aggregation process for particles in DLCA A particle flow code in three dimensions (PFC3D) [3] simulates mechanical behavior of mesoporous structures when a bonded assembly of spherical particles is available from DLCA, as described earlier. PFC3D is classified as a discrete or distinct element analysis code as it allows finite displacements and rotations of discrete bodies and recognizes new contacts automatically. PFC models are categorized as direct damage-type numerical models in which deformation is not a function of prescribed relationships between stress and strain but of changing microstructure. The numerical model is composed of distinct particles that displace independently from one another and interact only at contacts. Newton’s laws of motion provide the fundamental relations between particle motion and forces. The complex nature of mesoporous structures can be modeled by bonding particles together at their contact points and allowing the bond breakage for excessive loading to exceed the bond strength. The PFC3D conducts a particle flow model with the following assumptions: 1. The particles are treated as rigid bodies and are spherical in shape. The deformation of a packed-particle assembly results primarily from the sliding and rotation of rigid particles and not from the individual particle deformation. 2. Particles are in contact with each other. Contacts among the particles occur over a vanishingly small area, i.e., at a point, where bonds can exist. 3. Behavior at contacts uses a soft-contact approach wherein the particles are allowed to overlap one another at contact points. 4. The magnitude of the overlap is related with contact force via the force–displacement law, and all overlaps are small enough compared to particle sizes. In addition to spherical particles (referred to as “balls”), the PFC3D includes “walls” to apply velocity boundary conditions for compaction and confinement of particle assemblies. The balls and walls interact with one another via forces that arise at contacts. The equations of motion are satisfied Chapter 10: Modeling of Stiffness, Strength, and Structure 469