正在加载图片...

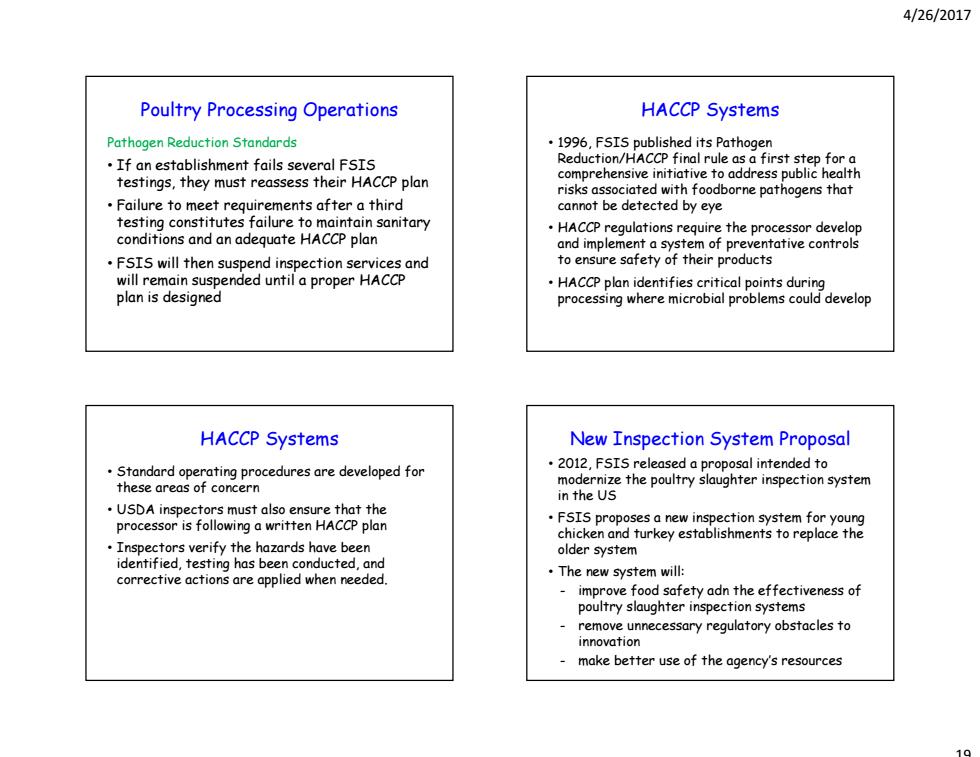

4/26/2017 Poultry Processing Operations HACCP Systems Pathogen Reduction Standards .199.FSIS published its Pathogen If an establishment fails several FSIS Reduction/HACCP final rule as a first step for a testings,they must reassess their HACCP plan comprehensive initiative to address public health risks associated with foodborne pathogens that Failure to meet requirements after a third cannot be detected by eye testing constitutes failure to maintain sanitary HACCP regulations require the processor develop conditions and an adequate HACCP plan and implement a system of preventative controls FSIS will then suspend inspection services and to ensure safety of their products will remain suspended until a proper HACCP HACCP plan identifies critical points during plan is designed processing where microbial problems could develop HACCP Systems New Inspection System Proposal Standard operating procedures are developed for 2012,FSIS released a proposal intended to these areas of concern modernize the poultry slaughter inspection system in the US USDA inspectors must also ensure that the processor is following a written HACCP plan ·85 r alhmen6n22 Inspectors verify the hazards have been older system identified,testing has been conducted,and corrective actions are applied when needed. ·The new system will: improve food safety adn the effectiveness of poultry slaughter inspection systems remove unnecessary regulatory obstacles to innovation make better use of the agency's resources4/26/2017 19 Poultry Processing Operations Pathogen Reduction Standards • If an establishment fails several FSIS testings, they must reassess their HACCP plan • Failure to meet requirements after a third testing constitutes failure to maintain sanitary conditions and an adequate HACCP plan • FSIS will then suspend inspection services and will remain suspended until a proper HACCP plan is designed HACCP Systems • 1996, FSIS published its Pathogen Reduction/HACCP final rule as a first step for a comprehensive initiative to address public health risks associated with foodborne pathogens that cannot be detected by eye • HACCP regulations require the processor develop and implement a system of preventative controls to ensure safety of their products • HACCP plan identifies critical points during processing where microbial problems could develop HACCP Systems • Standard operating procedures are developed for these areas of concern • USDA inspectors must also ensure that the processor is following a written HACCP plan • Inspectors verify the hazards have been identified, testing has been conducted, and corrective actions are applied when needed. New Inspection System Proposal • 2012, FSIS released a proposal intended to modernize the poultry slaughter inspection system in the US • FSIS proposes a new inspection system for young chicken and turkey establishments to replace the older system • The new system will: - improve food safety adn the effectiveness of poultry slaughter inspection systems - remove unnecessary regulatory obstacles to innovation - make better use of the agency’s resources