正在加载图片...

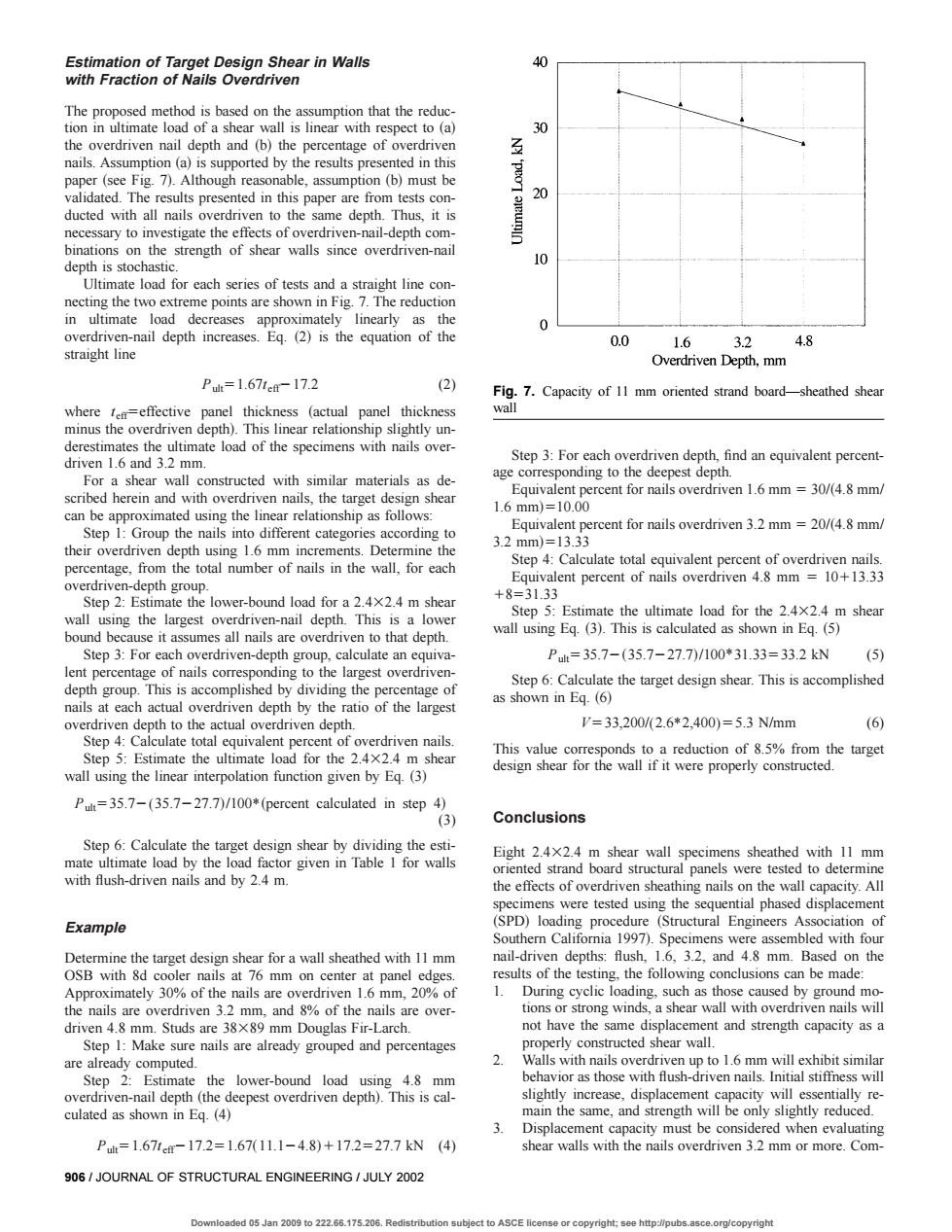

40 n that the redu 0 depth and (see F Fig.7).Although rea sonable,assumption (b)must be P0 results pre nted in this paper are from ests con necessary to investigate the effects of overdriven-nail-depth com binations on the strength of shear walls since overdriven-nail 10 Ultimate load for each series of tests and a straight line con- treme points are shown in Fig overdriven-nail depth increases.Eq.(2)is the equation of the 0 00 .6 4.8 straight line riven Dep h.mm P=1.671172 where t=effcctive minus the overdriven driven 1 and 32mm nalls over Step 3:Fo find an equivalent percent ra shear with similar ageconcpondingoied比petep can bea 16 ppr Step o different categories according to Equivalent percent for nails overdriven 3.2mm=20/(4.8 mm/ Group the nails int 32 nm) percentage from the total numbe late total e il of nails in the wall for each 0umd1 oad for324×24m 8 wall using the largest overdriven-nail depth.This is a lowe 5:Estimate the ultimate load for the 24x24 m shea wall using Eg.(3).This is calculated as shown in Eg.(5) Pt=35.7-(35.7-27.7)/100*31.33=33.2kN lent percentage of nailsco ing to the largest overdriven. depth group This isaccomplish the a ot the a V=33.200/2.6*2.400)=5.3N/mm (6) alcu lentperccntofovecrtrnemnail reduction of 85%from the target PA-357-357-27.7no (s6》 Conclusions Step:Calculate the s sheathed with 11 mm with fush-driven nails and by 2.4 m. 一3 dere d to女ee ential phas Example iation of 1.6,3.2and48 results of the testing. he following conclusions an be made 11.6mm,20%o e ove driven 4 mm Studs are 38x89 mm Douglas Fir-larch StepMakere nalsre aready grouped and perentages are to 16 mm will exhibit simila the lower-bound load usin 4.8 mm wil P=1.671-172=1.6711.1-48)+172=27.7kN(4 3 hen eva 906/JOURNAL OF STRUCTURAL ENGINEERING/JULY 2002 od 05 Jan 2009 to 222.65.175.206.Redistribution s t to ASCE lic Estimation of Target Design Shear in Walls with Fraction of Nails Overdriven The proposed method is based on the assumption that the reduction in ultimate load of a shear wall is linear with respect to ~a! the overdriven nail depth and ~b! the percentage of overdriven nails. Assumption ~a! is supported by the results presented in this paper ~see Fig. 7!. Although reasonable, assumption ~b! must be validated. The results presented in this paper are from tests conducted with all nails overdriven to the same depth. Thus, it is necessary to investigate the effects of overdriven-nail-depth combinations on the strength of shear walls since overdriven-nail depth is stochastic. Ultimate load for each series of tests and a straight line connecting the two extreme points are shown in Fig. 7. The reduction in ultimate load decreases approximately linearly as the overdriven-nail depth increases. Eq. ~2! is the equation of the straight line Pult51.67t eff217.2 (2) where t eff5effective panel thickness ~actual panel thickness minus the overdriven depth!. This linear relationship slightly underestimates the ultimate load of the specimens with nails overdriven 1.6 and 3.2 mm. For a shear wall constructed with similar materials as described herein and with overdriven nails, the target design shear can be approximated using the linear relationship as follows: Step 1: Group the nails into different categories according to their overdriven depth using 1.6 mm increments. Determine the percentage, from the total number of nails in the wall, for each overdriven-depth group. Step 2: Estimate the lower-bound load for a 2.432.4 m shear wall using the largest overdriven-nail depth. This is a lower bound because it assumes all nails are overdriven to that depth. Step 3: For each overdriven-depth group, calculate an equivalent percentage of nails corresponding to the largest overdrivendepth group. This is accomplished by dividing the percentage of nails at each actual overdriven depth by the ratio of the largest overdriven depth to the actual overdriven depth. Step 4: Calculate total equivalent percent of overdriven nails. Step 5: Estimate the ultimate load for the 2.432.4 m shear wall using the linear interpolation function given by Eq. ~3! Pult535.72~35.7227.7!/100*~percent calculated in step 4! (3) Step 6: Calculate the target design shear by dividing the estimate ultimate load by the load factor given in Table 1 for walls with flush-driven nails and by 2.4 m. Example Determine the target design shear for a wall sheathed with 11 mm OSB with 8d cooler nails at 76 mm on center at panel edges. Approximately 30% of the nails are overdriven 1.6 mm, 20% of the nails are overdriven 3.2 mm, and 8% of the nails are overdriven 4.8 mm. Studs are 38389 mm Douglas Fir-Larch. Step 1: Make sure nails are already grouped and percentages are already computed. Step 2: Estimate the lower-bound load using 4.8 mm overdriven-nail depth ~the deepest overdriven depth!. This is calculated as shown in Eq. ~4! Pult51.67t eff217.251.67~11.124.8!117.2527.7 kN (4) Step 3: For each overdriven depth, find an equivalent percentage corresponding to the deepest depth. Equivalent percent for nails overdriven 1.6 mm 5 30/~4.8 mm/ 1.6 mm!510.00 Equivalent percent for nails overdriven 3.2 mm 5 20/~4.8 mm/ 3.2 mm!513.33 Step 4: Calculate total equivalent percent of overdriven nails. Equivalent percent of nails overdriven 4.8 mm 5 10113.33 18531.33 Step 5: Estimate the ultimate load for the 2.432.4 m shear wall using Eq. ~3!. This is calculated as shown in Eq. ~5! Pult535.72~35.7227.7!/100*31.33533.2 kN (5) Step 6: Calculate the target design shear. This is accomplished as shown in Eq. ~6! V533,200/~2.6*2,400!55.3 N/mm (6) This value corresponds to a reduction of 8.5% from the target design shear for the wall if it were properly constructed. Conclusions Eight 2.432.4 m shear wall specimens sheathed with 11 mm oriented strand board structural panels were tested to determine the effects of overdriven sheathing nails on the wall capacity. All specimens were tested using the sequential phased displacement ~SPD! loading procedure ~Structural Engineers Association of Southern California 1997!. Specimens were assembled with four nail-driven depths: flush, 1.6, 3.2, and 4.8 mm. Based on the results of the testing, the following conclusions can be made: 1. During cyclic loading, such as those caused by ground motions or strong winds, a shear wall with overdriven nails will not have the same displacement and strength capacity as a properly constructed shear wall. 2. Walls with nails overdriven up to 1.6 mm will exhibit similar behavior as those with flush-driven nails. Initial stiffness will slightly increase, displacement capacity will essentially remain the same, and strength will be only slightly reduced. 3. Displacement capacity must be considered when evaluating shear walls with the nails overdriven 3.2 mm or more. ComFig. 7. Capacity of 11 mm oriented strand board—sheathed shear wall 906 / JOURNAL OF STRUCTURAL ENGINEERING / JULY 2002 Downloaded 05 Jan 2009 to 222.66.175.206. Redistribution subject to ASCE license or copyright; see http://pubs.asce.org/copyright