正在加载图片...

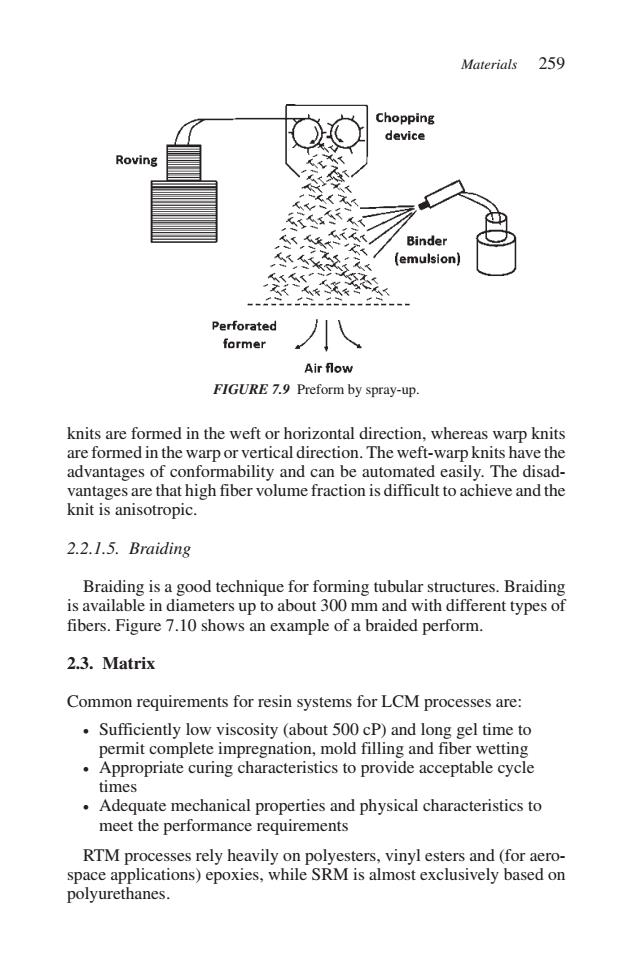

Materials 259 Chopping device Roving Binder (emulsion) Perforated former 小八 Air flow FIGURE 7.9 Preform by spray-up. knits are formed in the weft or horizontal direction,whereas warp knits are formed in the warp or vertical direction.The weft-warp knits have the advantages of conformability and can be automated easily.The disad- vantages are that high fiber volume fraction is difficult to achieve and the knit is anisotropic. 2.2.1.5.Braiding Braiding is a good technique for forming tubular structures.Braiding is available in diameters up to about 300 mm and with different types of fibers.Figure 7.10 shows an example of a braided perform. 2.3.Matrix Common requirements for resin systems for LCM processes are: Sufficiently low viscosity (about 500 cP)and long gel time to permit complete impregnation,mold filling and fiber wetting Appropriate curing characteristics to provide acceptable cycle times Adequate mechanical properties and physical characteristics to meet the performance requirements RTM processes rely heavily on polyesters,vinyl esters and(for aero- space applications)epoxies,while SRM is almost exclusively based on polyurethanes.knits are formed in the weft or horizontal direction, whereas warp knits are formed in the warp or vertical direction. The weft-warp knits have the advantages of conformability and can be automated easily. The disadvantages are that high fiber volume fraction is difficult to achieve and the knit is anisotropic. 2.2.1.5. Braiding Braiding is a good technique for forming tubular structures. Braiding is available in diameters up to about 300 mm and with different types of fibers. Figure 7.10 shows an example of a braided perform. 2.3. Matrix Common requirements for resin systems for LCM processes are: • Sufficiently low viscosity (about 500 cP) and long gel time to permit complete impregnation, mold filling and fiber wetting • Appropriate curing characteristics to provide acceptable cycle times • Adequate mechanical properties and physical characteristics to meet the performance requirements RTM processes rely heavily on polyesters, vinyl esters and (for aerospace applications) epoxies, while SRM is almost exclusively based on polyurethanes. Materials 259 FIGURE 7.9 Preform by spray-up