正在加载图片...

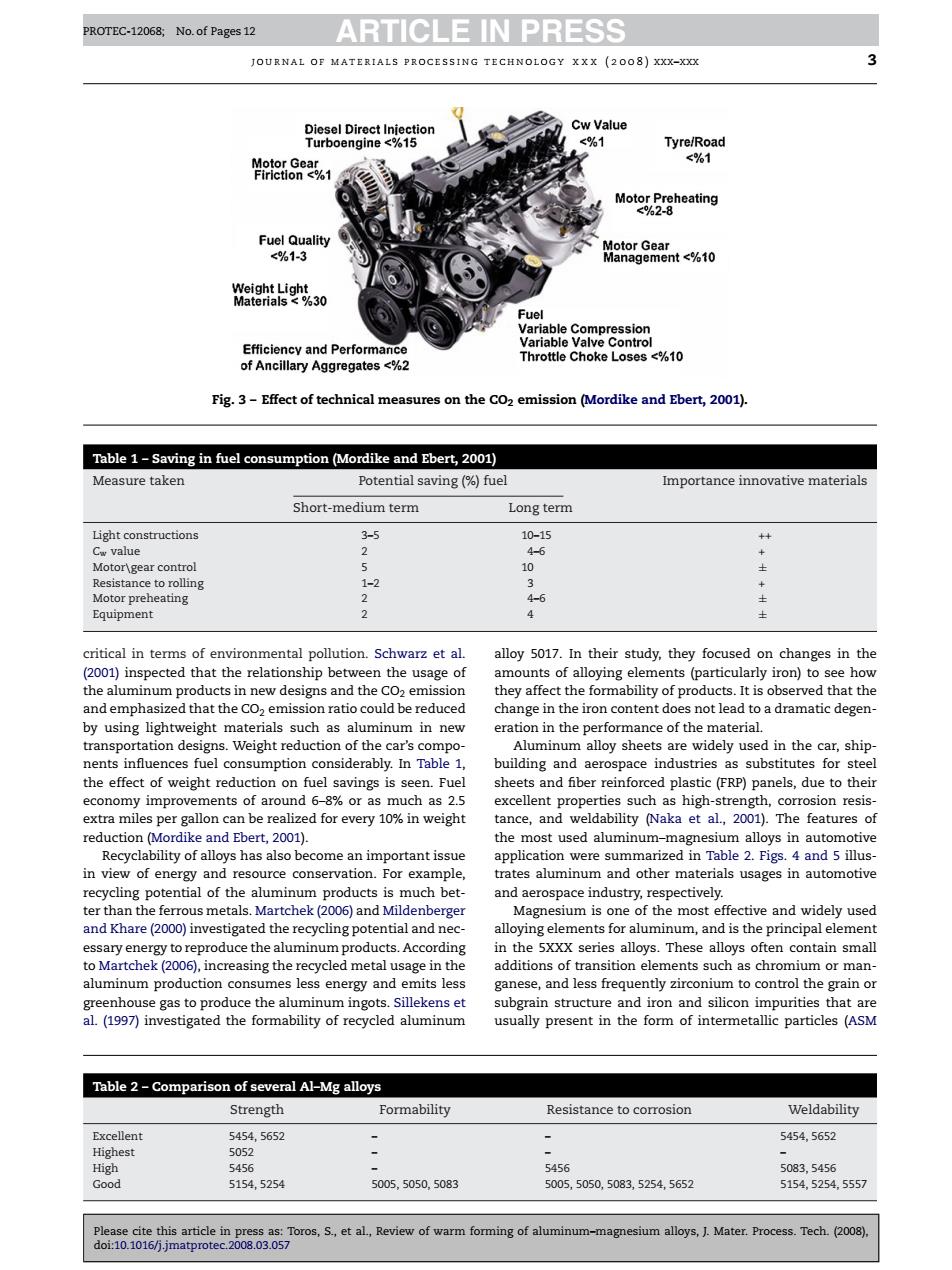

PROTEC-12068 No.of Pages1 ARTICLE IN PRESS JOURNAL OF MATERIALS PROCESSING TECHNOLOGY XXX (2008)XXX-XXX P9tao8Rgent1gegon oengine ico Motorheating Fuel Quality <%1-3 Meogeagnt<%tio Woton te Loses<%10 Fig.3-Effect of technical measures on the CO2 emission(Mordike and Ebert,2001). Table 1-Saving in fuel consumption(Mordike and Ebert,2001) Measure taken Potential saving (%fuel Importance innovative materials Short-medium term Long term 35 10-15 Motor\gear control 5 Resistance to rolling Motor preheating +士士 Equipment critical in terms of environmental pollution.Schwarz et al. alloy 5017.In their study,they focused on changes in the d that the change in the iron content does not lead to a dramatic degen- by using lightweight materials such as aluminum in new eration in the performance of the material. transportation designs.Weight reduction of the car's compo- Aluminum alloy sheets are widely used in the car,ship nents influences fuel consumption considerably.In Table 1 building and aerospace industries as substitutes for steel the effect of weight reduction on fuel savings is s sheets and fiber reinforced plastic(FRP)pa nels,due to their econom ents of aro 16-8%or as exeper gallon can be realized for every1weigh s high- tyCaka et al 2001)T atur of suc on resis we reduction(Mordike and Ebert,2001). the most used aluminum-magnesium alloys in automotive Recyclability of alloys has also become an important issue application were summarized in Table 2.Figs.4 and 5 illus- in view of energy and resource conservation.For example trates aluminum and other materials usages in automotive recycling potential of the aluminum products is much bet and aerospace industry,respectively. ter than the ferrous metals.Martchek (200)and Mildenb of the mo st effective and widely used and Khare (2000)investigated the recycling potential essary energy to reproduce the aluminum products.According in the 5XXX series alloys.These alloys often contain smal to Martchek(2006),increasing the recycled metal usage in the additions of transition elements such as chromium or man- aluminum production consumes less energy and emits less ganese,and less frequently zirconium to control the grain or greenhouse gas to produce the aluminum ingots.Sillekens et subgrain structure and iron and silicon impurities that are al.(1997)investigated the formability of recy cled aluminum usually present in the form of intermetallic particles(ASM Table 2-Comparison of several Al-Mg alloys Strength Formability Resistance to corrosion Weldability Excellen 5454,5652 5454,5652 545e 5083.5456 5154,5254 5005,5050,5083 5005,5050.5083,5254,5652 5154,5254,5557 Please cite this article in press as: Toros, S., et al., Review of warm forming of aluminum–magnesium alloys, J. Mater. Process. Tech. (2008), doi:10.1016/j.jmatprotec.2008.03.057 PROTEC-12068; No. of Pages 12 ARTICLE IN PRESS journal of materials processing technology xxx (2008) xxx–xxx 3 Fig. 3 – Effect of technical measures on the CO2 emission (Mordike and Ebert, 2001). Table 1 – Saving in fuel consumption (Mordike and Ebert, 2001) Measure taken Potential saving (%) fuel Importance innovative materials Short-medium term Long term Light constructions 3–5 10–15 ++ Cw value 2 4–6 + Motor\gear control 5 10 ± Resistance to rolling 1–2 3 + Motor preheating 2 4–6 ± Equipment 2 4 ± critical in terms of environmental pollution. Schwarz et al. (2001) inspected that the relationship between the usage of the aluminum products in new designs and the CO2 emission and emphasized that the CO2 emission ratio could be reduced by using lightweight materials such as aluminum in new transportation designs. Weight reduction of the car’s components influences fuel consumption considerably. In Table 1, the effect of weight reduction on fuel savings is seen. Fuel economy improvements of around 6–8% or as much as 2.5 extra miles per gallon can be realized for every 10% in weight reduction (Mordike and Ebert, 2001). Recyclability of alloys has also become an important issue in view of energy and resource conservation. For example, recycling potential of the aluminum products is much better than the ferrous metals. Martchek (2006) and Mildenberger and Khare (2000) investigated the recycling potential and necessary energy to reproduce the aluminum products. According to Martchek (2006), increasing the recycled metal usage in the aluminum production consumes less energy and emits less greenhouse gas to produce the aluminum ingots. Sillekens et al. (1997) investigated the formability of recycled aluminum alloy 5017. In their study, they focused on changes in the amounts of alloying elements (particularly iron) to see how they affect the formability of products. It is observed that the change in the iron content does not lead to a dramatic degeneration in the performance of the material. Aluminum alloy sheets are widely used in the car, shipbuilding and aerospace industries as substitutes for steel sheets and fiber reinforced plastic (FRP) panels, due to their excellent properties such as high-strength, corrosion resistance, and weldability (Naka et al., 2001). The features of the most used aluminum–magnesium alloys in automotive application were summarized in Table 2. Figs. 4 and 5 illustrates aluminum and other materials usages in automotive and aerospace industry, respectively. Magnesium is one of the most effective and widely used alloying elements for aluminum, and is the principal element in the 5XXX series alloys. These alloys often contain small additions of transition elements such as chromium or manganese, and less frequently zirconium to control the grain or subgrain structure and iron and silicon impurities that are usually present in the form of intermetallic particles (ASM Table 2 – Comparison of several Al–Mg alloys Strength Formability Resistance to corrosion Weldability Excellent 5454, 5652 – – 5454, 5652 Highest 5052 – – – High 5456 – 5456 5083, 5456 Good 5154, 5254 5005, 5050, 5083 5005, 5050, 5083, 5254, 5652 5154, 5254, 5557