正在加载图片...

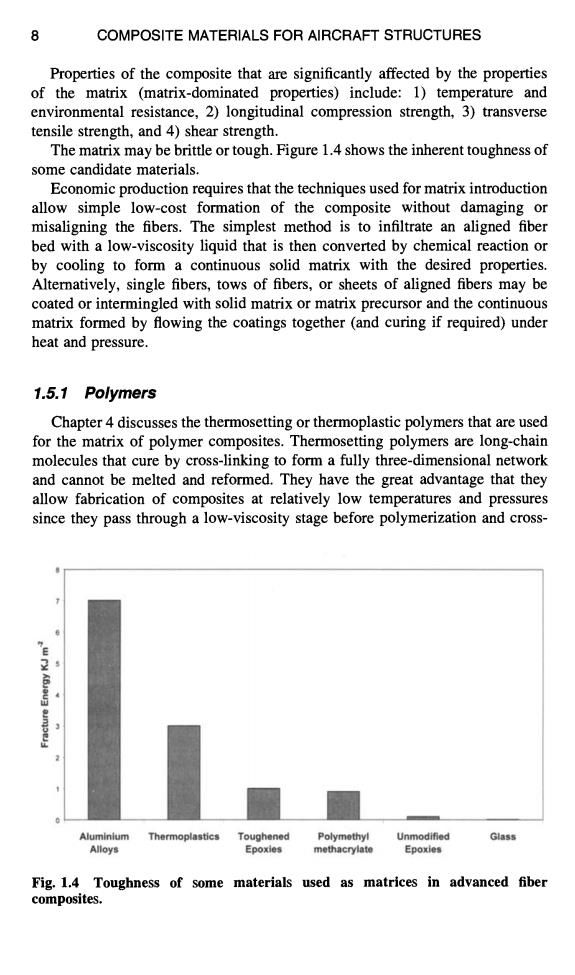

8 COMPOSITE MATERIALS FOR AIRCRAFT STRUCTURES Properties of the composite that are significantly affected by the properties of the matrix (matrix-dominated properties)include:1)temperature and environmental resistance,2)longitudinal compression strength,3)transverse tensile strength,and 4)shear strength. The matrix may be brittle or tough.Figure 1.4 shows the inherent toughness of some candidate materials. Economic production requires that the techniques used for matrix introduction allow simple low-cost formation of the composite without damaging or misaligning the fibers.The simplest method is to infiltrate an aligned fiber bed with a low-viscosity liquid that is then converted by chemical reaction or by cooling to form a continuous solid matrix with the desired properties. Alternatively,single fibers,tows of fibers,or sheets of aligned fibers may be coated or intermingled with solid matrix or matrix precursor and the continuous matrix formed by flowing the coatings together (and curing if required)under heat and pressure. 1.5.1 Polymers Chapter 4 discusses the thermosetting or thermoplastic polymers that are used for the matrix of polymer composites.Thermosetting polymers are long-chain molecules that cure by cross-linking to form a fully three-dimensional network and cannot be melted and reformed.They have the great advantage that they allow fabrication of composites at relatively low temperatures and pressures since they pass through a low-viscosity stage before polymerization and cross- 3 Aluminium Thermoplastics Toughened Polymethyl Unmodified Glass Alloys Epoxies methacrylate Epoxies Fig.1.4 Toughness of some materials used as matrices in advanced fiber composites.8 COMPOSITE MATERIALS FOR AIRCRAFT STRUCTURES Properties of the composite that are significantly affected by the properties of the matrix (matrix-dominated properties) include: 1) temperature and environmental resistance, 2) longitudinal compression strength, 3) transverse tensile strength, and 4) shear strength. The matrix may be brittle or tough. Figure 1.4 shows the inherent toughness of some candidate materials. Economic production requires that the techniques used for matrix introduction allow simple low-cost formation of the composite without damaging or misaligning the fibers. The simplest method is to infiltrate an aligned fiber bed with a low-viscosity liquid that is then converted by chemical reaction or by cooling to form a continuous solid matrix with the desired properties. Alternatively, single fibers, tows of fibers, or sheets of aligned fibers may be coated or intermingled with solid matrix or matrix precursor and the continuous matrix formed by flowing the coatings together (and curing if required) under heat and pressure. 1.5.1 Polymers Chapter 4 discusses the thermosetting or thermoplastic polymers that are used for the matrix of polymer composites. Thermosetting polymers are long-chain molecules that cure by cross-linking to form a fully three-dimensional network and cannot be melted and reformed. They have the great advantage that they allow fabrication of composites at relatively low temperatures and pressures since they pass through a low-viscosity stage before polymerization and crossLu Alumlnlum Thermoplastics Alloys Fig. 1.4 Toughness of some composites. Toughened Polymethyl Unmodified Glass Epoxies methacrylate Epoxies materials used as matrices in advanced fiber