正在加载图片...

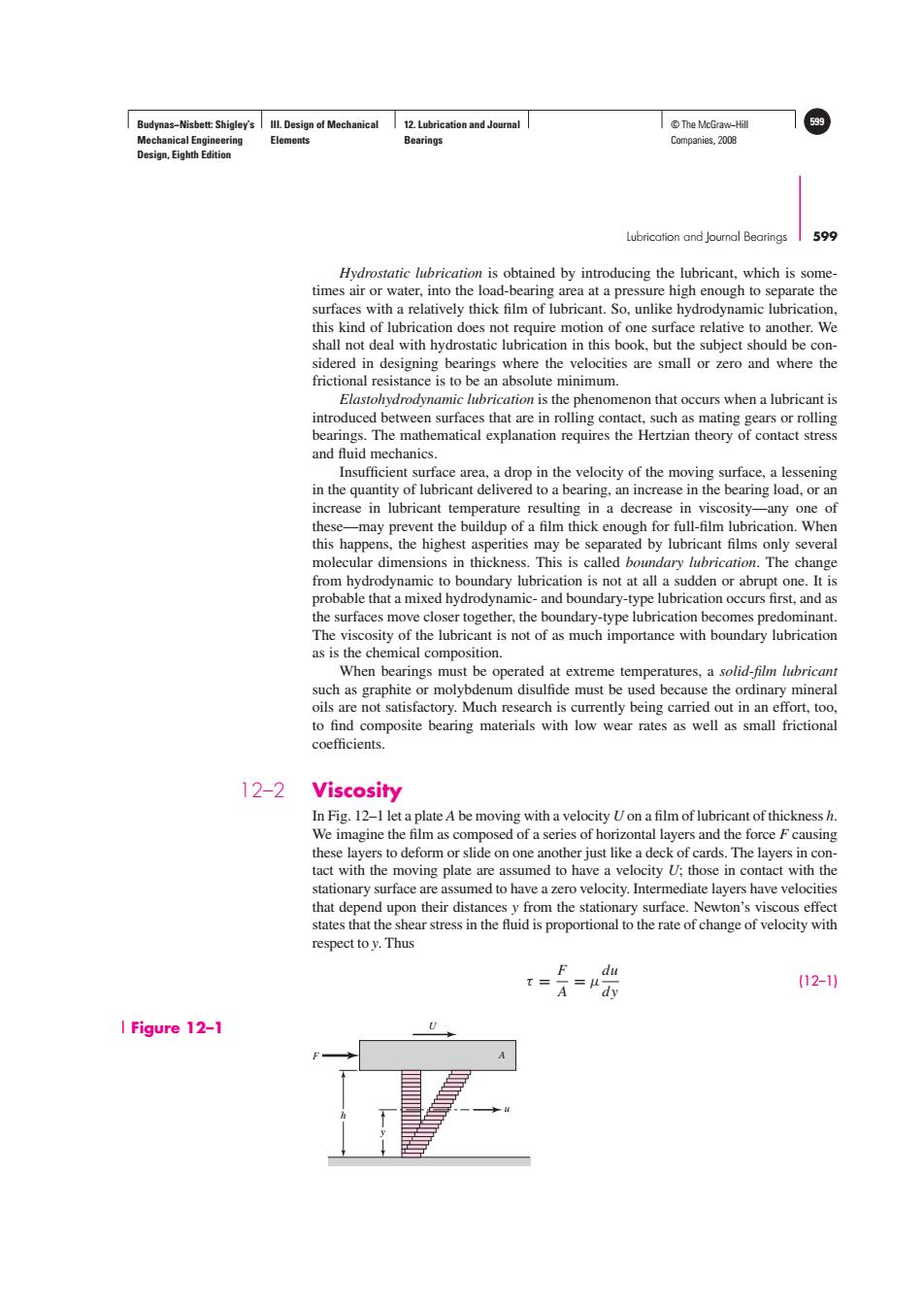

Budynas-Nisbett:Shigley's Ill.Design of Mechanical 12.Lubrication and Journal T©The McGraw-Hill 59 Mechanical Engineering Elements Bearings Companies,2008 Design,Eighth Edition Lubrication and Journal Bearings 599 Hydrostatic lubrication is obtained by introducing the lubricant,which is some- times air or water,into the load-bearing area at a pressure high enough to separate the surfaces with a relatively thick film of lubricant.So,unlike hydrodynamic lubrication, this kind of lubrication does not require motion of one surface relative to another.We shall not deal with hydrostatic lubrication in this book,but the subject should be con- sidered in designing bearings where the velocities are small or zero and where the frictional resistance is to be an absolute minimum. Elastohydrodynamic lubrication is the phenomenon that occurs when a lubricant is introduced between surfaces that are in rolling contact,such as mating gears or rolling bearings.The mathematical explanation requires the Hertzian theory of contact stress and fluid mechanics. Insufficient surface area,a drop in the velocity of the moving surface,a lessening in the quantity of lubricant delivered to a bearing,an increase in the bearing load,or an increase in lubricant temperature resulting in a decrease in viscosity-any one of these-may prevent the buildup of a film thick enough for full-film lubrication.When this happens,the highest asperities may be separated by lubricant films only several molecular dimensions in thickness.This is called boundary lubrication.The change from hydrodynamic to boundary lubrication is not at all a sudden or abrupt one.It is probable that a mixed hydrodynamic-and boundary-type lubrication occurs first,and as the surfaces move closer together,the boundary-type lubrication becomes predominant. The viscosity of the lubricant is not of as much importance with boundary lubrication as is the chemical composition. When bearings must be operated at extreme temperatures,a solid-film lubricant such as graphite or molybdenum disulfide must be used because the ordinary mineral oils are not satisfactory.Much research is currently being carried out in an effort,too, to find composite bearing materials with low wear rates as well as small frictional coefficients. 12-2 Viscosity In Fig.12-1 let a plate A be moving with a velocity U on a film of lubricant of thickness h. We imagine the film as composed of a series of horizontal layers and the force F causing these layers to deform or slide on one another just like a deck of cards.The layers in con- tact with the moving plate are assumed to have a velocity U;those in contact with the stationary surface are assumed to have a zero velocity.Intermediate layers have velocities that depend upon their distances y from the stationary surface.Newton's viscous effect states that the shear stress in the fluid is proportional to the rate of change of velocity with respect to y.Thus F du T A=H (12-11 dy I Figure 12-1Budynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition III. Design of Mechanical Elements 12. Lubrication and Journal Bearings © The McGraw−Hill 599 Companies, 2008 Lubrication and Journal Bearings 599 Figure 12–1 F u h y U A Hydrostatic lubrication is obtained by introducing the lubricant, which is sometimes air or water, into the load-bearing area at a pressure high enough to separate the surfaces with a relatively thick film of lubricant. So, unlike hydrodynamic lubrication, this kind of lubrication does not require motion of one surface relative to another. We shall not deal with hydrostatic lubrication in this book, but the subject should be considered in designing bearings where the velocities are small or zero and where the frictional resistance is to be an absolute minimum. Elastohydrodynamic lubrication is the phenomenon that occurs when a lubricant is introduced between surfaces that are in rolling contact, such as mating gears or rolling bearings. The mathematical explanation requires the Hertzian theory of contact stress and fluid mechanics. Insufficient surface area, a drop in the velocity of the moving surface, a lessening in the quantity of lubricant delivered to a bearing, an increase in the bearing load, or an increase in lubricant temperature resulting in a decrease in viscosity—any one of these—may prevent the buildup of a film thick enough for full-film lubrication. When this happens, the highest asperities may be separated by lubricant films only several molecular dimensions in thickness. This is called boundary lubrication. The change from hydrodynamic to boundary lubrication is not at all a sudden or abrupt one. It is probable that a mixed hydrodynamic- and boundary-type lubrication occurs first, and as the surfaces move closer together, the boundary-type lubrication becomes predominant. The viscosity of the lubricant is not of as much importance with boundary lubrication as is the chemical composition. When bearings must be operated at extreme temperatures, a solid-film lubricant such as graphite or molybdenum disulfide must be used because the ordinary mineral oils are not satisfactory. Much research is currently being carried out in an effort, too, to find composite bearing materials with low wear rates as well as small frictional coefficients. 12–2 Viscosity In Fig. 12–1 let a plate A be moving with a velocity U on a film of lubricant of thickness h. We imagine the film as composed of a series of horizontal layers and the force F causing these layers to deform or slide on one another just like a deck of cards. The layers in contact with the moving plate are assumed to have a velocity U; those in contact with the stationary surface are assumed to have a zero velocity. Intermediate layers have velocities that depend upon their distances y from the stationary surface. Newton’s viscous effect states that the shear stress in the fluid is proportional to the rate of change of velocity with respect to y. Thus τ = F A = μ du dy (12–1)