正在加载图片...

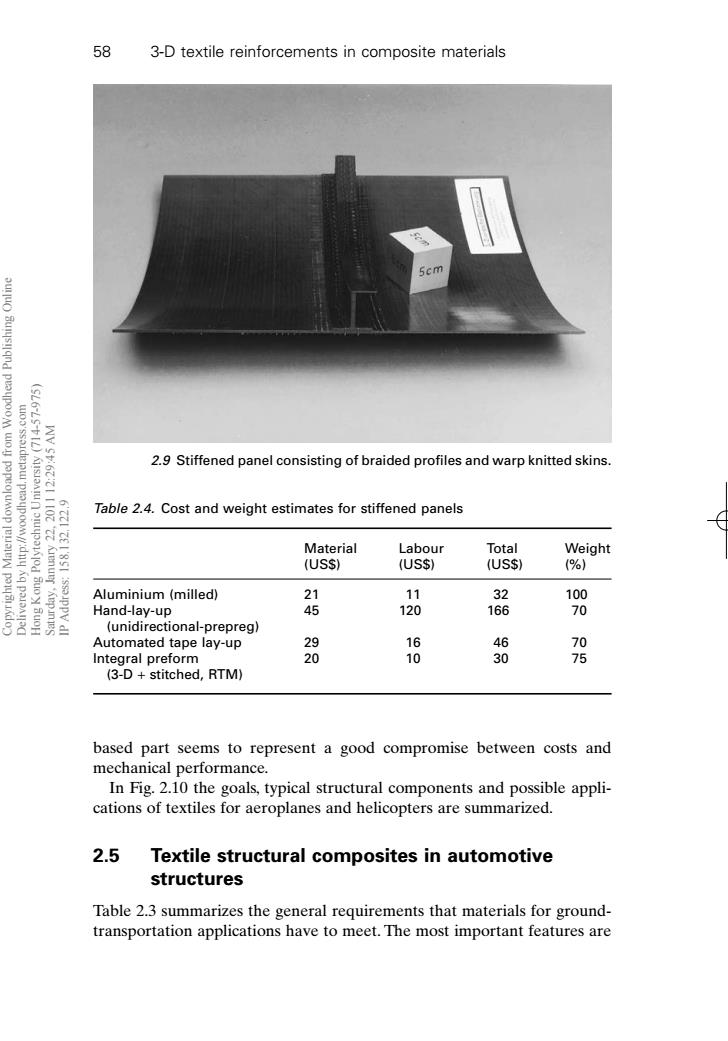

58 3-D textile reinforcements in composite materials 5cm wo'ssaudmau'puoupoo//dny WV St:6Z 2.9 Stiffened panel consisting of braided profiles and warp knitted skins. 2102 Table 2.4.Cost and weight estimates for stiffened panels Material Labour Total Weight (US$) (US$) (US$) (%) 云 Aluminium (milled) 21 11 32 100 Hand-lay-up 45 120 166 70 (unidirectional-prepreg) Automated tape lay-up 29 16 46 70 Integral preform 20 10 30 75 (3-D stitched,RTM) based part seems to represent a good compromise between costs and mechanical performance. In Fig.2.10 the goals,typical structural components and possible appli- cations of textiles for aeroplanes and helicopters are summarized. 2.5 Textile structural composites in automotive structures Table 2.3 summarizes the general requirements that materials for ground- transportation applications have to meet.The most important features arebased part seems to represent a good compromise between costs and mechanical performance. In Fig. 2.10 the goals, typical structural components and possible applications of textiles for aeroplanes and helicopters are summarized. 2.5 Textile structural composites in automotive structures Table 2.3 summarizes the general requirements that materials for groundtransportation applications have to meet. The most important features are 58 3-D textile reinforcements in composite materials 2.9 Stiffened panel consisting of braided profiles and warp knitted skins. Table 2.4. Cost and weight estimates for stiffened panels Material Labour Total Weight (US$) (US$) (US$) (%) Aluminium (milled) 21 11 32 100 Hand-lay-up 45 120 166 70 (unidirectional-prepreg) Automated tape lay-up 29 16 46 70 Integral preform 20 10 30 75 (3-D + stitched, RTM) RIC2 7/10/99 7:25 PM Page 58 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:29:45 AM IP Address: 158.132.122.9