正在加载图片...

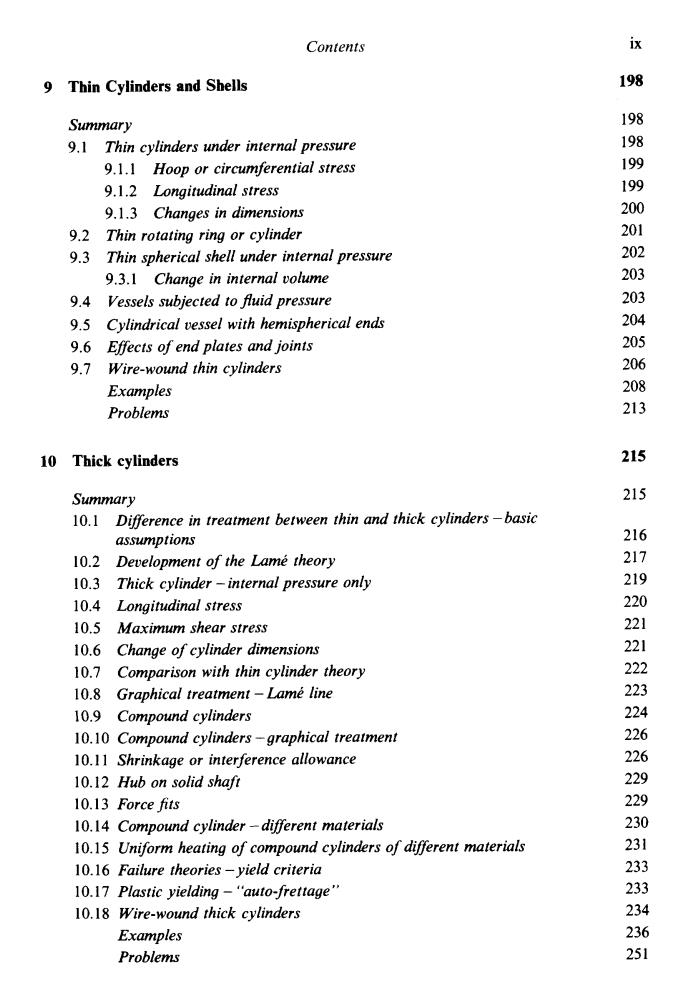

Contents ix 9 Thin Cylinders and Shells 198 Summary 198 9.1 Thin cylinders under internal pressure 198 9.1.1 Hoop or circumferential stress 199 9.1.2 Longitudinal stress 199 9.1.3 Changes in dimensions 200 9.2 Thin rotating ring or cylinder 201 9.3 Thin spherical shell under internal pressure 202 9.3.1 Change in internal volume 203 9.4 Vessels subjected to fluid pressure 203 9.5 Cylindrical vessel with hemispherical ends 204 9.6 Effects of end plates and joints 205 9.7 Wire-wound thin cylinders 206 Examples 208 Problems 213 10 Thick cylinders 215 Summary 215 10.1 Difference in treatment between thin and thick cylinders-basic assumptions 216 10.2 Development of the Lame theory 217 10.3 Thick cylinder -internal pressure only 219 10.4 Longitudinal stress 220 10.5 Maximum shear stress 221 10.6 Change of cylinder dimensions 221 10.7 Comparison with thin cylinder theory 222 10.8 Graphical treatment-Lame line 10.9 Compound cylinders 224 10.10 Compound cylinders-graphical treatment 10.11 Shrinkage or interference allowance 10.12 Hub on solid shaft 10.13 Force fits 229 10.14 Compound cylinder-different materials 10.15 Uniform heating of compound cylinders of different materials 231 10.16 Failure theories-yield criteria 233 10.17 Plastic yielding-"auto-frettage" 233 10.18 Wire-wound thick cylinders 234 Examples 236 Problems 251Contents 9 Thin Cylinders and Shells ix 198 Summary 9.1 Thin cylinders under internal pressure 9.1.1 Hoop or circumferential stress 9.1.2 Longitudinal stress 9.1.3 Changes in dimensions Thin rotating ring or cylinder Thin spherical shell under internal pressure 9.3.1 Change in internal volume Vessels subjected to JIuid pressure Cylindrical vessel with hemispherical end Effects of end plates and joints Examples Problems 9.2 9.3 9.4 9.5 9.6 9.7 Wire-wound thin cylinders 10 Thick cylinders Summary 10.1 10.2 10.3 10.4 Longitudinal stress 10.5 Maximum shear stress 10.6 Change of cylinder dimensions 10.7 10.8 10.9 Compound cylinders 10.10 Compound cylinders -graphical treatment 10.1 1 Shrinkage or interference allowance 10.12 Hub on solid shaji 10.13 Force fits 10.14 Compound cylinder -different materials 10.15 Uniform heating of compound cylinders of different materials 10.16 Failure theories -yield criteria 10.17 Plastic yielding - “auto-frettage” 10.18 Wire-wound thick cylinders Difference in treatment between thin and thick cylinders -basic assumptions Development of the Lame theory Thick cylinder - internal pressure only Comparison with thin cylinder theory Graphical treatment - Lame line Examples Problems 198 198 199 199 200 20 1 202 203 203 204 205 206 208 213 215 215 216 217 219 220 22 1 22 1 222 223 224 226 226 229 229 230 23 1 233 233 234 236 25 1