正在加载图片...

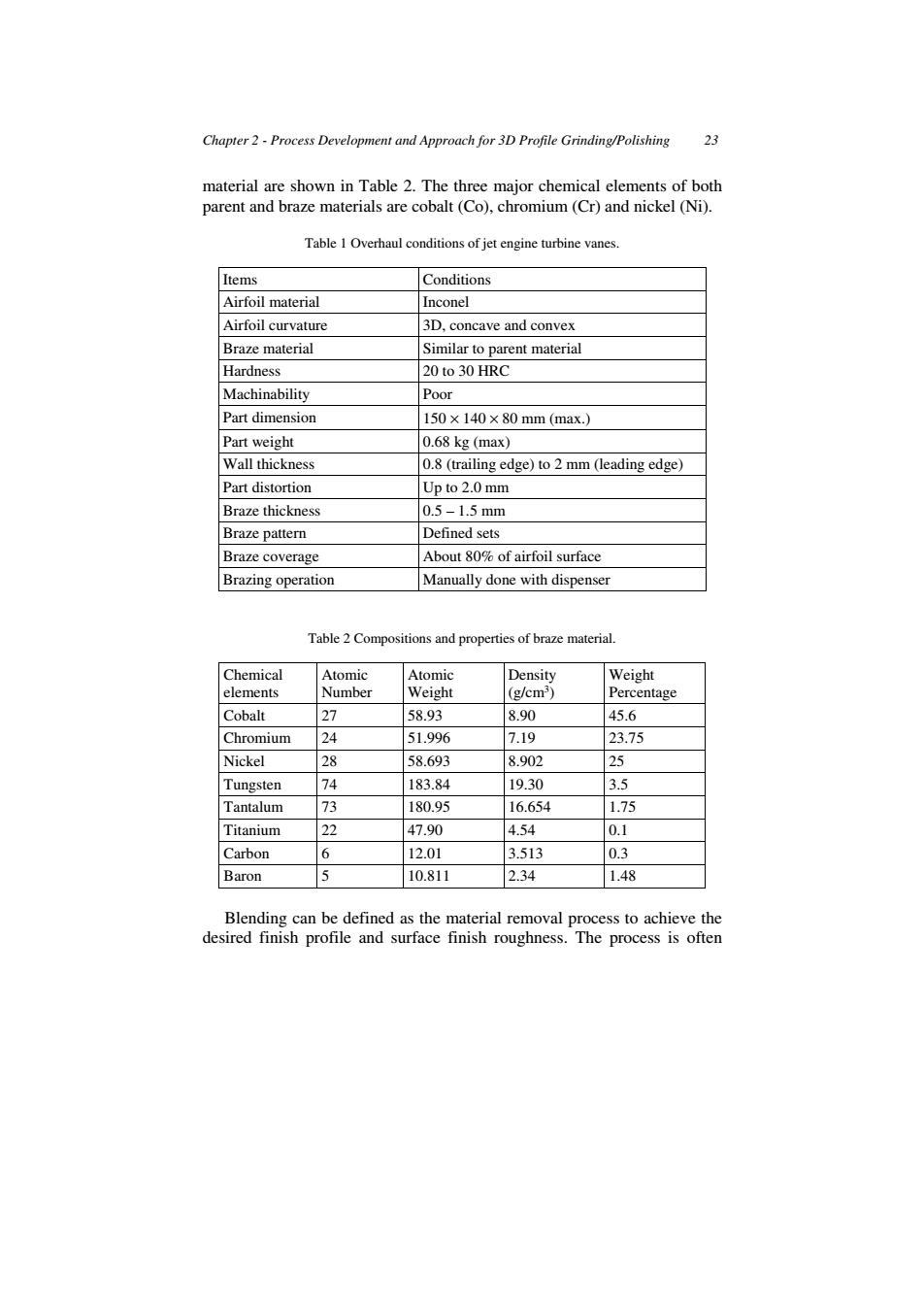

Chapter 2-Process Development and Approach for 3D Profile Grinding/Polishing 23 material are shown in Table 2.The three major chemical elements of both parent and braze materials are cobalt(Co),chromium(Cr)and nickel (Ni). Table 1 Overhaul conditions of jet engine turbine vanes. Items Conditions Airfoil material Inconel Airfoil curvature 3D,concave and convex Braze material Similar to parent material Hardness 20 to 30 HRC Machinability Poor Part dimension 150×140×80mm(max.) Part weight 0.68 kg (max) Wall thickness 0.8(trailing edge)to 2 mm (leading edge) Part distortion Up to 2.0 mm Braze thickness 0.5-1.5mm Braze pattern Defined sets Braze coverage About 80%of airfoil surface Brazing operation Manually done with dispenser Table 2 Compositions and properties of braze material. Chemical Atomic Atomic Density Weight elements Number Weight (g/cm3) Percentage Cobalt 27 58.93 8.90 45.6 Chromium 24 51.996 7.19 23.75 Nickel 28 58.693 8.902 25 Tungsten 74 183.84 19.30 3.5 Tantalum 73 180.95 16.654 1.75 Titanium 22 47.90 4.54 0.1 Carbon 6 12.01 3.513 0.3 Baron 5 10.811 2.34 1.48 Blending can be defined as the material removal process to achieve the desired finish profile and surface finish roughness.The process is oftenChapter 2 - Process Development and Approach for 3D Profile Grinding/Polishing 23 material are shown in Table 2. The three major chemical elements of both parent and braze materials are cobalt (Co), chromium (Cr) and nickel (Ni). Table 1 Overhaul conditions of jet engine turbine vanes. Items Conditions Airfoil material Inconel Airfoil curvature 3D, concave and convex Braze material Similar to parent material Hardness 20 to 30 HRC Machinability Poor Part dimension 150 × 140 × 80 mm (max.) Part weight 0.68 kg (max) Wall thickness 0.8 (trailing edge) to 2 mm (leading edge) Part distortion Up to 2.0 mm Braze thickness 0.5 – 1.5 mm Braze pattern Defined sets Braze coverage About 80% of airfoil surface Brazing operation Manually done with dispenser Table 2 Compositions and properties of braze material. Chemical elements Atomic Number Atomic Weight Density (g/cm3 ) Weight Percentage Cobalt 27 58.93 8.90 45.6 Chromium 24 51.996 7.19 23.75 Nickel 28 58.693 8.902 25 Tungsten 74 183.84 19.30 3.5 Tantalum 73 180.95 16.654 1.75 Titanium 22 47.90 4.54 0.1 Carbon 6 12.01 3.513 0.3 Baron 5 10.811 2.34 1.48 Blending can be defined as the material removal process to achieve the desired finish profile and surface finish roughness. The process is often