正在加载图片...

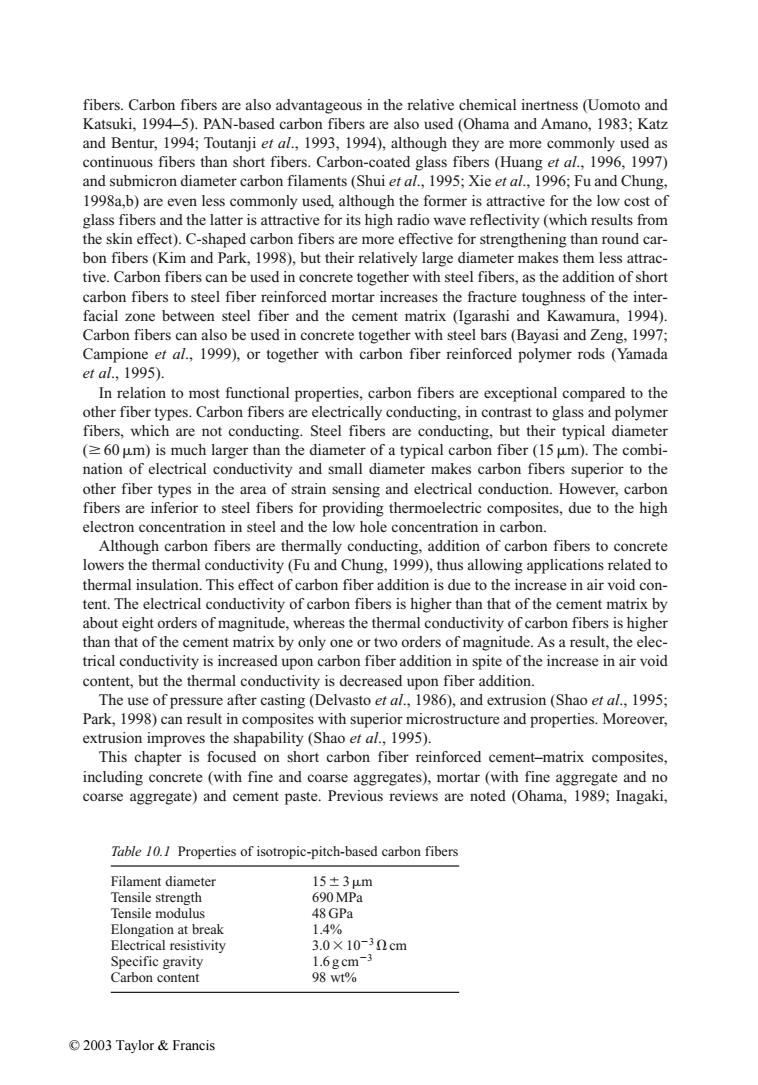

fibers.Carbon fibers are also advantageous in the relative chemical inertness(Uomoto and Katsuki,1994-5).PAN-based carbon fibers are also used(Ohama and Amano,1983;Katz and Bentur,1994;Toutanji et al.,1993,1994),although they are more commonly used as continuous fibers than short fibers.Carbon-coated glass fibers (Huang et al.,1996,1997) and submicron diameter carbon filaments(Shui et al.,1995;Xie et al.,1996;Fu and Chung, 1998a,b)are even less commonly used,although the former is attractive for the low cost of glass fibers and the latter is attractive for its high radio wave reflectivity(which results from the skin effect).C-shaped carbon fibers are more effective for strengthening than round car- bon fibers(Kim and Park,1998),but their relatively large diameter makes them less attrac- tive.Carbon fibers can be used in concrete together with steel fibers,as the addition of short carbon fibers to steel fiber reinforced mortar increases the fracture toughness of the inter- facial zone between steel fiber and the cement matrix (Igarashi and Kawamura,1994). Carbon fibers can also be used in concrete together with steel bars(Bayasi and Zeng,1997; Campione et al.,1999),or together with carbon fiber reinforced polymer rods (Yamada etal,1995). In relation to most functional properties,carbon fibers are exceptional compared to the other fiber types.Carbon fibers are electrically conducting,in contrast to glass and polymer fibers,which are not conducting.Steel fibers are conducting,but their typical diameter (60 um)is much larger than the diameter of a typical carbon fiber(15 um).The combi- nation of electrical conductivity and small diameter makes carbon fibers superior to the other fiber types in the area of strain sensing and electrical conduction.However,carbon fibers are inferior to steel fibers for providing thermoelectric composites,due to the high electron concentration in steel and the low hole concentration in carbon. Although carbon fibers are thermally conducting,addition of carbon fibers to concrete lowers the thermal conductivity (Fu and Chung,1999),thus allowing applications related to thermal insulation.This effect of carbon fiber addition is due to the increase in air void con- tent.The electrical conductivity of carbon fibers is higher than that of the cement matrix by about eight orders of magnitude,whereas the thermal conductivity of carbon fibers is higher than that of the cement matrix by only one or two orders of magnitude.As a result,the elec- trical conductivity is increased upon carbon fiber addition in spite of the increase in air void content,but the thermal conductivity is decreased upon fiber addition. The use of pressure after casting (Delvasto et al.,1986),and extrusion(Shao et al.,1995; Park,1998)can result in composites with superior microstructure and properties.Moreover, extrusion improves the shapability (Shao et al.,1995). This chapter is focused on short carbon fiber reinforced cement-matrix composites, including concrete(with fine and coarse aggregates),mortar(with fine aggregate and no coarse aggregate)and cement paste.Previous reviews are noted (Ohama,1989;Inagaki, Table 10.I Properties of isotropic-pitch-based carbon fibers Filament diameter 15±3μm Tensile strength 690 MPa Tensile modulus 48GPa Elongation at break 1.4% Electrical resistivity 3.0×10-30cm Specific gravity 1.6gcm-3 Carbon content 98wt% ©2003 Taylor&Francisfibers. Carbon fibers are also advantageous in the relative chemical inertness (Uomoto and Katsuki, 1994–5). PAN-based carbon fibers are also used (Ohama and Amano, 1983; Katz and Bentur, 1994; Toutanji et al., 1993, 1994), although they are more commonly used as continuous fibers than short fibers. Carbon-coated glass fibers (Huang et al., 1996, 1997) and submicron diameter carbon filaments (Shui et al., 1995; Xie et al., 1996; Fu and Chung, 1998a,b) are even less commonly used, although the former is attractive for the low cost of glass fibers and the latter is attractive for its high radio wave reflectivity (which results from the skin effect). C-shaped carbon fibers are more effective for strengthening than round carbon fibers (Kim and Park, 1998), but their relatively large diameter makes them less attractive. Carbon fibers can be used in concrete together with steel fibers, as the addition of short carbon fibers to steel fiber reinforced mortar increases the fracture toughness of the interfacial zone between steel fiber and the cement matrix (Igarashi and Kawamura, 1994). Carbon fibers can also be used in concrete together with steel bars (Bayasi and Zeng, 1997; Campione et al., 1999), or together with carbon fiber reinforced polymer rods (Yamada et al., 1995). In relation to most functional properties, carbon fibers are exceptional compared to the other fiber types. Carbon fibers are electrically conducting, in contrast to glass and polymer fibers, which are not conducting. Steel fibers are conducting, but their typical diameter ( 60m) is much larger than the diameter of a typical carbon fiber (15m). The combination of electrical conductivity and small diameter makes carbon fibers superior to the other fiber types in the area of strain sensing and electrical conduction. However, carbon fibers are inferior to steel fibers for providing thermoelectric composites, due to the high electron concentration in steel and the low hole concentration in carbon. Although carbon fibers are thermally conducting, addition of carbon fibers to concrete lowers the thermal conductivity (Fu and Chung, 1999), thus allowing applications related to thermal insulation. This effect of carbon fiber addition is due to the increase in air void content. The electrical conductivity of carbon fibers is higher than that of the cement matrix by about eight orders of magnitude, whereas the thermal conductivity of carbon fibers is higher than that of the cement matrix by only one or two orders of magnitude. As a result, the electrical conductivity is increased upon carbon fiber addition in spite of the increase in air void content, but the thermal conductivity is decreased upon fiber addition. The use of pressure after casting (Delvasto et al., 1986), and extrusion (Shao et al., 1995; Park, 1998) can result in composites with superior microstructure and properties. Moreover, extrusion improves the shapability (Shao et al., 1995). This chapter is focused on short carbon fiber reinforced cement–matrix composites, including concrete (with fine and coarse aggregates), mortar (with fine aggregate and no coarse aggregate) and cement paste. Previous reviews are noted (Ohama, 1989; Inagaki, Table 10.1 Properties of isotropic-pitch-based carbon fibers Filament diameter 15 3m Tensile strength 690 MPa Tensile modulus 48 GPa Elongation at break 1.4% Electrical resistivity 3.0

103 cm Specific gravity 1.6 g cm3 Carbon content 98 wt% © 2003 Taylor & Francis