正在加载图片...

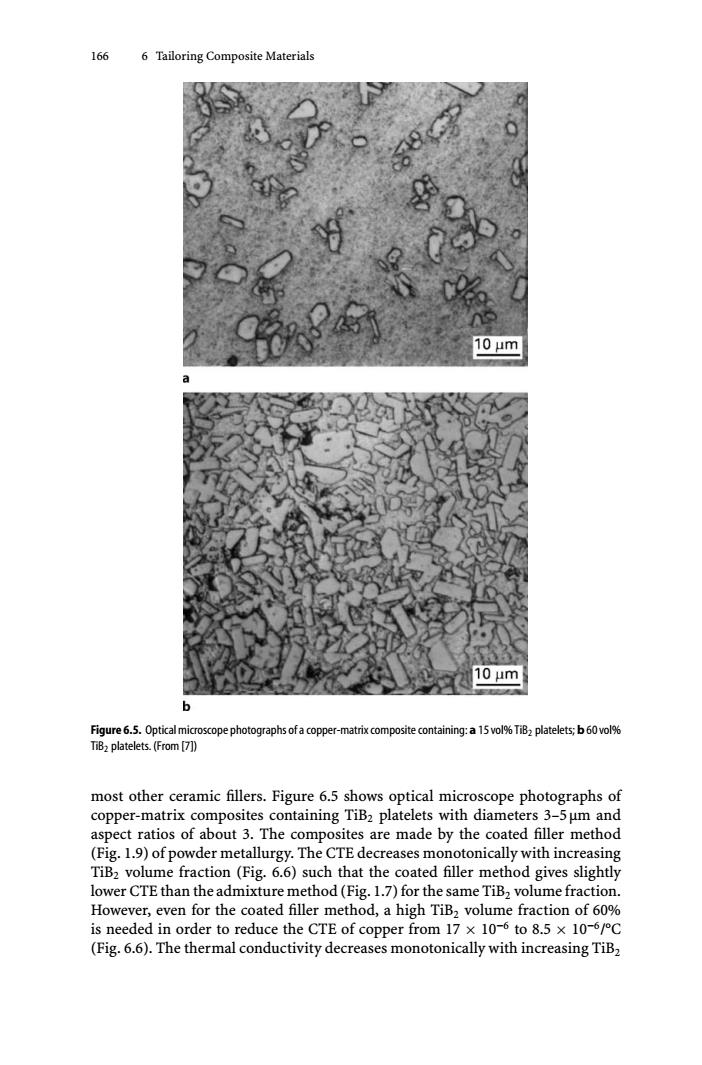

166 6 Tailoring Composite Materials 10μm 10μm b Figure6.5.Optical microscopephotographs of a copper-matrix composite containing:a 15vol%TiB2 platelets;b60vol% TiB2 platelets.(From [7]) most other ceramic fillers.Figure 6.5 shows optical microscope photographs of copper-matrix composites containing TiB2 platelets with diameters 3-5um and aspect ratios of about 3.The composites are made by the coated filler method (Fig.1.9)of powder metallurgy.The CTE decreases monotonically with increasing TiBz volume fraction (Fig.6.6)such that the coated filler method gives slightly lower CTE than the admixture method (Fig.1.7)for the same TiB,volume fraction. However,even for the coated filler method,a high TiB,volume fraction of 60% is needed in order to reduce the CTE of copper from 17 x 10-6 to 8.5 x 10-6/C (Fig.6.6).The thermal conductivity decreases monotonically with increasing TiBz166 6 Tailoring Composite Materials Figure 6.5. Optical microscope photographs of a copper-matrix composite containing: a 15vol% TiB2 platelets; b 60vol% TiB2 platelets. (From [7]) most other ceramic fillers. Figure 6.5 shows optical microscope photographs of copper-matrix composites containing TiB2 platelets with diameters 3–5μm and aspect ratios of about 3. The composites are made by the coated filler method (Fig. 1.9) of powder metallurgy. The CTE decreases monotonically with increasing TiB2 volume fraction (Fig. 6.6) such that the coated filler method gives slightly lower CTE than the admixture method (Fig. 1.7) for the same TiB2 volume fraction. However, even for the coated filler method, a high TiB2 volume fraction of 60% is needed in order to reduce the CTE of copper from 17 × 10−6 to 8.5 × 10−6/°C (Fig. 6.6). The thermal conductivity decreases monotonically with increasing TiB2