正在加载图片...

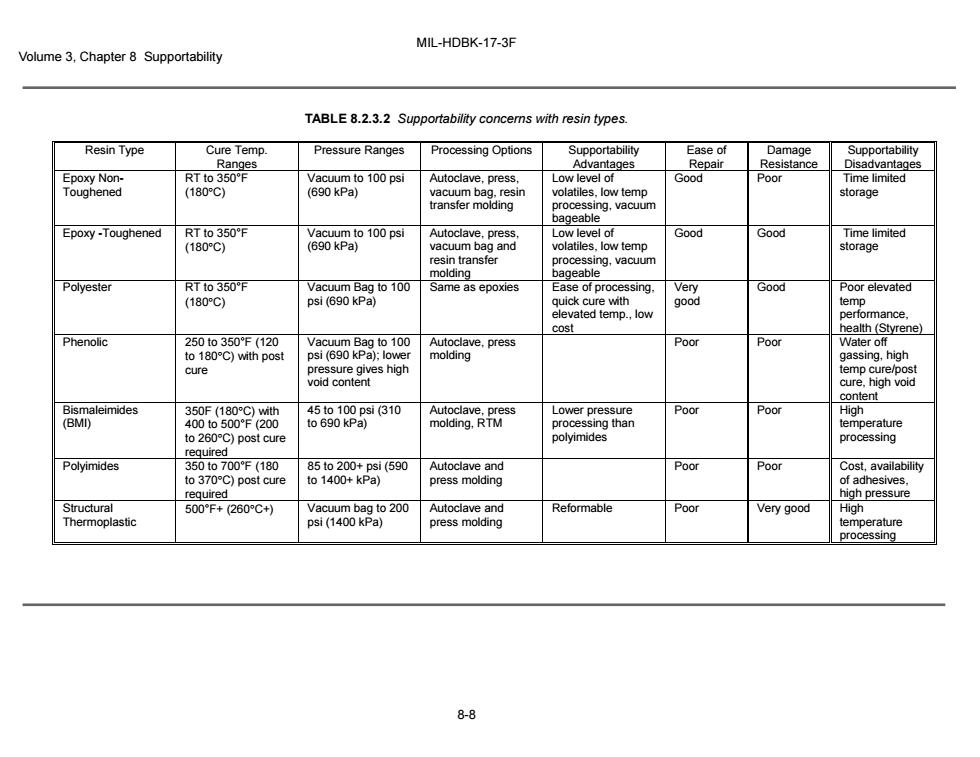

MIL-HDBK-17-3F Volume 3,Chapter 8 Supportability TABLE 8.2.3.2 Supportability concerns with resin types. Resin Type Cure Temp. Pressure Ranges Processing Options Supportability Ease of Damage Supportability Ranges Advantages Repair Resistance Disadvantages Epoxy Non- RT to 350F Vacuum to 100 psi Autoclave,press, Low level of Good Poor Time limited Toughened (180C) (690kPa) vacuum bag,resin volatiles,low temp storage transfer molding processing,vacuum bageable Epoxy -Toughened RTto350℉ Vacuum to 100 psi Autoclave,press, Low level of Good Good Time limited (180C) (690kPa) vacuum bag and volatiles,low temp storage resin transfer processing,vacuum molding bageable Polyester RTt0350℉ Vacuum Bag to 100 Same as epoxies Ease of processing. Very Good Poor elevated (180℃) psi(690 kPa) quick cure with good temp elevated temp.,low performance, cost health (Styrene) Phenolic 250to350℉(120 Vacuum Bag to 100 Autoclave,press Poor Poor Water off to 180C)with post psi (690 kPa);lower molding gassing,high cure pressure gives high temp cure/post void content cure.high void content Bismaleimides 350F(180C)wth 45to100psi(310 Autoclave,press Lower pressure Poor Poor High (BMI) 400to500°℉(200 to 690 kPa) molding,RTM processing than temperature to 260C)post cure polyimides processing required Polyimides 350to700℉(180 85to200+psi(590 Autoclave and Poor Poor Cost,availability to 370C)post cure to 1400+kPa) press molding of adhesives, required high pressure Structural 500℉+(260C+) Vacuum bag to 200 Autoclave and Reformable Poor Very good High Thermoplastic psi(1400 kPa) press molding temperature processing 8-8MIL-HDBK-17-3F Volume 3, Chapter 8 Supportability 8-8 TABLE 8.2.3.2 Supportability concerns with resin types. Resin Type Cure Temp. Ranges Pressure Ranges Processing Options Supportability Advantages Ease of Repair Damage Resistance Supportability Disadvantages Epoxy NonToughened RT to 350°F (180°C) Vacuum to 100 psi (690 kPa) Autoclave, press, vacuum bag, resin transfer molding Low level of volatiles, low temp processing, vacuum bageable Good Poor Time limited storage Epoxy -Toughened RT to 350°F (180°C) Vacuum to 100 psi (690 kPa) Autoclave, press, vacuum bag and resin transfer molding Low level of volatiles, low temp processing, vacuum bageable Good Good Time limited storage Polyester RT to 350°F (180°C) Vacuum Bag to 100 psi (690 kPa) Same as epoxies Ease of processing, quick cure with elevated temp., low cost Very good Good Poor elevated temp performance, health (Styrene) Phenolic 250 to 350°F (120 to 180°C) with post cure Vacuum Bag to 100 psi (690 kPa); lower pressure gives high void content Autoclave, press molding Poor Poor Water off gassing, high temp cure/post cure, high void content Bismaleimides (BMI) 350F (180°C) with 400 to 500°F (200 to 260°C) post cure required 45 to 100 psi (310 to 690 kPa) Autoclave, press molding, RTM Lower pressure processing than polyimides Poor Poor High temperature processing Polyimides 350 to 700°F (180 to 370°C) post cure required 85 to 200+ psi (590 to 1400+ kPa) Autoclave and press molding Poor Poor Cost, availability of adhesives, high pressure Structural Thermoplastic 500°F+ (260°C+) Vacuum bag to 200 psi (1400 kPa) Autoclave and press molding Reformable Poor Very good High temperature processing