正在加载图片...

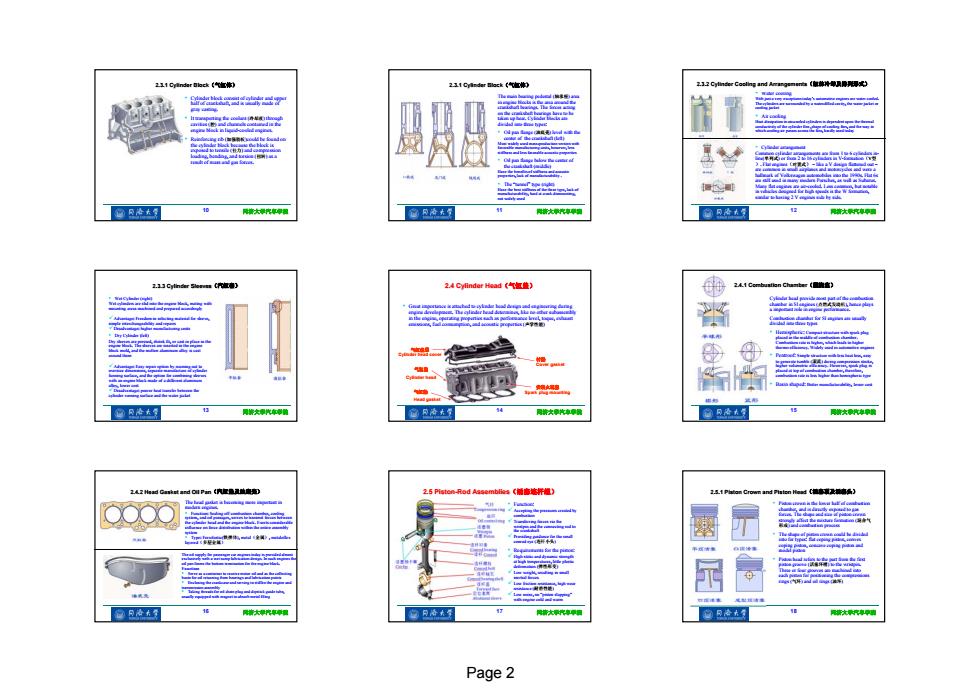

11G 白韩H单要厚得式5 gi Madk 5-omdnd 物R冷大写 窗凡冷大气 的R冷大写 2.4 Cyfinder Head《气氢维】 贸 11 2 42 Head Carket and0Pan《度量 25Pm每ten-Rod Assemblies(壶毫开量) 1L1 Pistan Crown and Plsten HeadC事设0结%》 2 气 物凡冷? 16 Page 2Page 2 10 同济大学汽车学院 • Cylinder block consist of cylinder and upper half of crankshaft, and is usually made of gray casting. • It transporting the coolant (冷却液) through cavities (腔) and channels contained in the engine block in liquid-cooled engines. • Reinforcing rib (加强肋板)could be found on the cylinder block because the block is exposed to tensile (拉力) and compression loading, bending, and torsion (扭转) as a result of mass and gas forces. 2.3.1 Cylinder Block(气缸体) 11 同济大学汽车学院 The main bearing pedestal (轴承座) area in engine blocks is the area around the crankshaft bearings. The forces acting on the crankshaft bearings have to be taken up hear. Cylinder blocks are divided into three types: • Oil pan flange (油底壳) level with the center of the crankshaft (left) Most widely used mass-production version with favorable manufacturing costs, however, less stiffness and less favorable acoustic properties • Oil pan flange below the center of the crankshaft (middle) Have the benefits of stiffness and acoustic properties, lack of manufacturability . • The “tunnel” type (right) Have the best stiffness of the three type, lack of manufacturability, hard at crank dismounting, not widely used 2.3.1 Cylinder Block(气缸体) 12 同济大学汽车学院 • Water cooling With just a very exceptions today’s automotive engines are water cooled. The cylinders are surrounded by a water-filled cavity, the water jacket or cooling jacket • Air cooling Heat dissipation in air-cooled cylinders is dependent upon the thermal conductivity of the cylinder fins ,shape of cooling fins, and the way in which cooling air passes across the fins, hardly used today 2.3.2 Cylinder Cooling and Arrangements(缸体冷却及排列形式) • Cylinder arrangement Common cylinder arrangements are from 1 to 6 cylinders inline(单列式) or from 2 to 16 cylinders in V-formation(V型 ). Flat engines(对置式) – like a V design flattened out – are common in small airplanes and motorcycles and were a hallmark of Volkswagen automobiles into the 1990s. Flat 6s are still used in many modern Porsches, as well as Subarus. Many flat engines are air-cooled. Less common, but notable in vehicles designed for high speeds is the W formation, similar to having 2 V engines side by side. 13 同济大学汽车学院 • Wet Cylinder (right) Wet cylinders are slid into the engine block, mating with mounting areas machined and prepared accordingly Advantage: Freedom in selecting material for sleeve, simple interchangeability and repairs Disadvantage: higher manufacturing costs • Dry Cylinder (left) Dry sleeves are pressed, shrink fit, or cast in place in the engine block. The sleeves are inserted in the engine block mold, and the molten aluminum alloy is cast around them Advantage: Easy repair option by reaming out to oversize dimensions, separate manufacture of cylinder funning surface, and the option for combining sleeves with an engine block made of a different aluminum alloy, lower cost Disadvantage: poorer heat transfer between the cylinder running surface and the water jacket 2.3.3 Cylinder Sleeves(汽缸套) 14 同济大学汽车学院 • Great importance is attached to cylinder head design and engineering during engine development. The cylinder head determines, like no other subassembly in the engine, operating properties such as performance level, toque, exhaust emissions, fuel consumption, and acoustic properties (声学性能) 2.4 Cylinder Head(气缸盖) 气缸盖罩 Cylinder head cover 气缸盖 Cylinder head 气缸垫 Head gasket 衬垫 Cover gasket 安装火花塞 Spark plug mounting 15 同济大学汽车学院 Cylinder head provide most part of the combustion chamber in SI engines (点燃式发动机), hence plays a important role in engine performance. Combustion chamber for SI engines are usually divided into three types • Hemispheric: Compact structure with spark plug placed in the middle of combustion chamber. Combustion rate is higher, which leads to higher thermo efficiency. Widely used in automotive engines • Pentroof: Simple structure with less heat loss, easy to generate tumble (滚流) during compression stroke, higher volumetric efficiency. However, spark plug is placed at top of combustion chamber, therefore, combustion rate is less higher than hemispheric type • Basin shaped: Better manufacturability, lower cost 2.4.1 Combustion Chamber(燃烧室) 16 同济大学汽车学院 The head gasket is becoming more important in modern engines. • Function: Sealing off combustion chamber, cooling system, and oil passages, serves to transmit forces between the cylinder head and the engine block. Exerts considerable influence on force distribution within the entire assembly system • Type: Ferrolastic(铁弹体), metal(金属), metaloflex layered(多层金属) 2.4.2 Head Gasket and Oil Pan(汽缸垫及油底壳) The oil supply for passenger car engines today is provided almost exclusively with a wet sump lubrication design. In such engines the oil pan forms the bottom termination for the engine block. Function: • Serve as a container to receive motor oil and as the collecting basin for oil returning from bearings and lubrication points • Enclosing the crankcase and serving to stiffen the engine and transmission assembly • Taking threads for oil drain plug and dipstick guide tube, usually equipped with magnet to absorb metal filing 17 同济大学汽车学院 • Function: Accepting the pressures created by combustion Transferring forces via the wristpin and the connecting rod to the crankshaft Providing guidance for the small conrod eye (连杆小头) • Requirements for the piston: High static and dynamic strength at high temperatures, little plastic deformation (弹性形变) Low weight, resulting in small inertial forces Low friction resistance, high wear resistance (耐磨性能) Low noise, no “piston slapping” with engine cold and warm 2.5 Piston-Rod Assemblies(活塞连杆组) 18 同济大学汽车学院 • Piston crown is the lower half of combustion chamber, and is directly exposed to gas forces. The shape and size of piston crown strongly affect the mixture formation (混合气 形成) and combustion process • The shape of piston crown could be divided into for types: flat coping piston, convex coping piston, concave coping piston and model piston • Piston head refers to the part from the first piston groove (活塞环槽) to the wristpin. Three or four grooves are machined into each piston for positioning the compressions rings (气环) and oil rings (油环) 2.5.1 Piston Crown and Piston Head(活塞顶及活塞头)