正在加载图片...

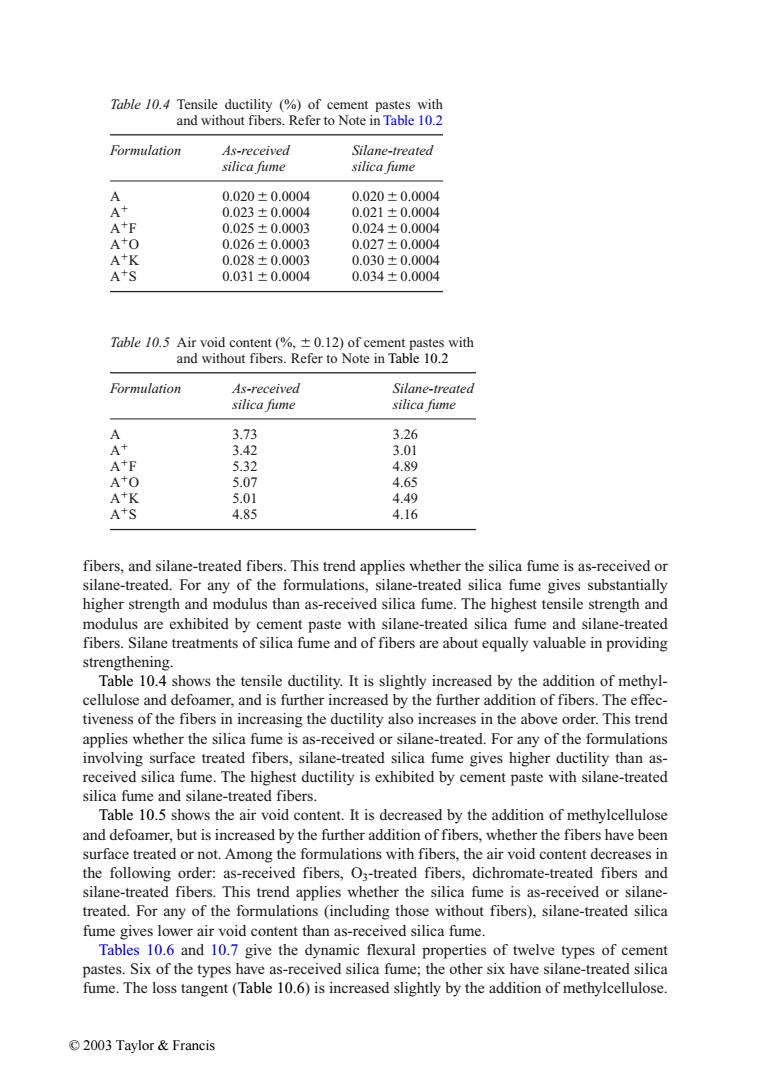

Table 10.4 Tensile ductility (%of cement pastes with and without fibers.Refer to Note in Table 10.2 Formulation As-received Silane-treated silica fume silica fume A 0.020±0.0004 0.020±0.0004 A+ 0.023±0.0004 0.021±0.0004 A+F 0.025±0.0003 0.024±0.0004 AO 0.026±0.0003 0.027±0.0004 AK 0.028±0.0003 0.030±0.0004 A+S 0.031±0.0004 0.034±0.0004 Table 10.5 Air void content(%,0.12)of cement pastes with and without fibers.Refer to Note in Table 10.2 Formulation As-received Silane-treated silica fume silica fume A 3.73 3.26 A+ 3.42 3.01 A+F 5.32 4.89 AO 5.07 4.65 A+K 5.01 4.49 A+S 4.85 4.16 fibers,and silane-treated fibers.This trend applies whether the silica fume is as-received or silane-treated.For any of the formulations,silane-treated silica fume gives substantially higher strength and modulus than as-received silica fume.The highest tensile strength and modulus are exhibited by cement paste with silane-treated silica fume and silane-treated fibers.Silane treatments of silica fume and of fibers are about equally valuable in providing strengthening. Table 10.4 shows the tensile ductility.It is slightly increased by the addition of methyl- cellulose and defoamer,and is further increased by the further addition of fibers.The effec- tiveness of the fibers in increasing the ductility also increases in the above order.This trend applies whether the silica fume is as-received or silane-treated.For any of the formulations involving surface treated fibers,silane-treated silica fume gives higher ductility than as- received silica fume.The highest ductility is exhibited by cement paste with silane-treated silica fume and silane-treated fibers. Table 10.5 shows the air void content.It is decreased by the addition of methylcellulose and defoamer,but is increased by the further addition of fibers,whether the fibers have been surface treated or not.Among the formulations with fibers,the air void content decreases in the following order:as-received fibers,O;-treated fibers,dichromate-treated fibers and silane-treated fibers.This trend applies whether the silica fume is as-received or silane- treated.For any of the formulations (including those without fibers),silane-treated silica fume gives lower air void content than as-received silica fume. Tables 10.6 and 10.7 give the dynamic flexural properties of twelve types of cement pastes.Six of the types have as-received silica fume;the other six have silane-treated silica fume.The loss tangent(Table 10.6)is increased slightly by the addition of methylcellulose. ©2003 Taylor&Francisfibers, and silane-treated fibers. This trend applies whether the silica fume is as-received or silane-treated. For any of the formulations, silane-treated silica fume gives substantially higher strength and modulus than as-received silica fume. The highest tensile strength and modulus are exhibited by cement paste with silane-treated silica fume and silane-treated fibers. Silane treatments of silica fume and of fibers are about equally valuable in providing strengthening. Table 10.4 shows the tensile ductility. It is slightly increased by the addition of methylcellulose and defoamer, and is further increased by the further addition of fibers. The effectiveness of the fibers in increasing the ductility also increases in the above order. This trend applies whether the silica fume is as-received or silane-treated. For any of the formulations involving surface treated fibers, silane-treated silica fume gives higher ductility than asreceived silica fume. The highest ductility is exhibited by cement paste with silane-treated silica fume and silane-treated fibers. Table 10.5 shows the air void content. It is decreased by the addition of methylcellulose and defoamer, but is increased by the further addition of fibers, whether the fibers have been surface treated or not. Among the formulations with fibers, the air void content decreases in the following order: as-received fibers, O3-treated fibers, dichromate-treated fibers and silane-treated fibers. This trend applies whether the silica fume is as-received or silanetreated. For any of the formulations (including those without fibers), silane-treated silica fume gives lower air void content than as-received silica fume. Tables 10.6 and 10.7 give the dynamic flexural properties of twelve types of cement pastes. Six of the types have as-received silica fume; the other six have silane-treated silica fume. The loss tangent (Table 10.6) is increased slightly by the addition of methylcellulose. Table 10.4 Tensile ductility (%) of cement pastes with and without fibers. Refer to Note in Table 10.2 Formulation As-received Silane-treated silica fume silica fume A 0.020 0.0004 0.020 0.0004 A 0.023 0.0004 0.021 0.0004 AF 0.025 0.0003 0.024 0.0004 AO 0.026 0.0003 0.027 0.0004 AK 0.028 0.0003 0.030 0.0004 AS 0.031 0.0004 0.034 0.0004 Table 10.5 Air void content (%, 0.12) of cement pastes with and without fibers. Refer to Note in Table 10.2 Formulation As-received Silane-treated silica fume silica fume A 3.73 3.26 A 3.42 3.01 AF 5.32 4.89 AO 5.07 4.65 AK 5.01 4.49 AS 4.85 4.16 © 2003 Taylor & Francis����������