正在加载图片...

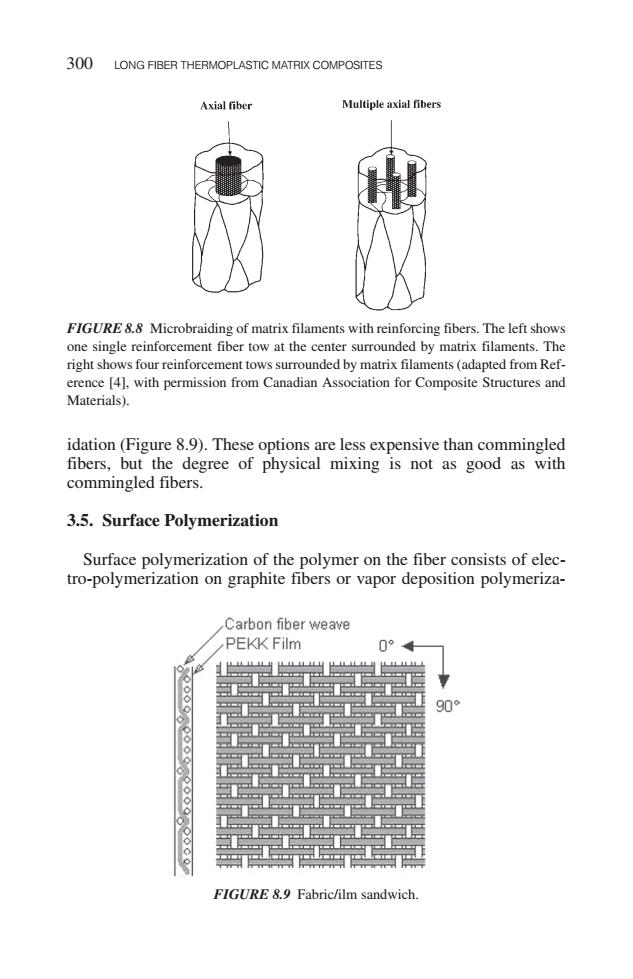

300 LONG FIBER THERMOPLASTIC MATRIX COMPOSITES Axial fiber Multiple axial fibers FIGURE 8.8 Microbraiding of matrix filaments with reinforcing fibers.The left shows one single reinforcement fiber tow at the center surrounded by matrix filaments.The right shows four reinforcement tows surrounded by matrix filaments(adapted from Ref- erence [4],with permission from Canadian Association for Composite Structures and Materials). idation(Figure 8.9).These options are less expensive than commingled fibers,but the degree of physical mixing is not as good as with commingled fibers. 3.5.Surface Polymerization Surface polymerization of the polymer on the fiber consists of elec- tro-polymerization on graphite fibers or vapor deposition polymeriza- Carbon fiber weave PEKK Film 0° 90 FIGURE 8.9 Fabric/ilm sandwich.idation (Figure 8.9). These options are less expensive than commingled fibers, but the degree of physical mixing is not as good as with commingled fibers. 3.5. Surface Polymerization Surface polymerization of the polymer on the fiber consists of electro-polymerization on graphite fibers or vapor deposition polymeriza- 300 LONG FIBER THERMOPLASTIC MATRIX COMPOSITES FIGURE 8.8 Microbraiding of matrix filaments with reinforcing fibers. The left shows one single reinforcement fiber tow at the center surrounded by matrix filaments. The right shows four reinforcement tows surrounded by matrix filaments (adapted from Reference [4], with permission from Canadian Association for Composite Structures and Materials). FIGURE 8.9 Fabric/ilm sandwich