正在加载图片...

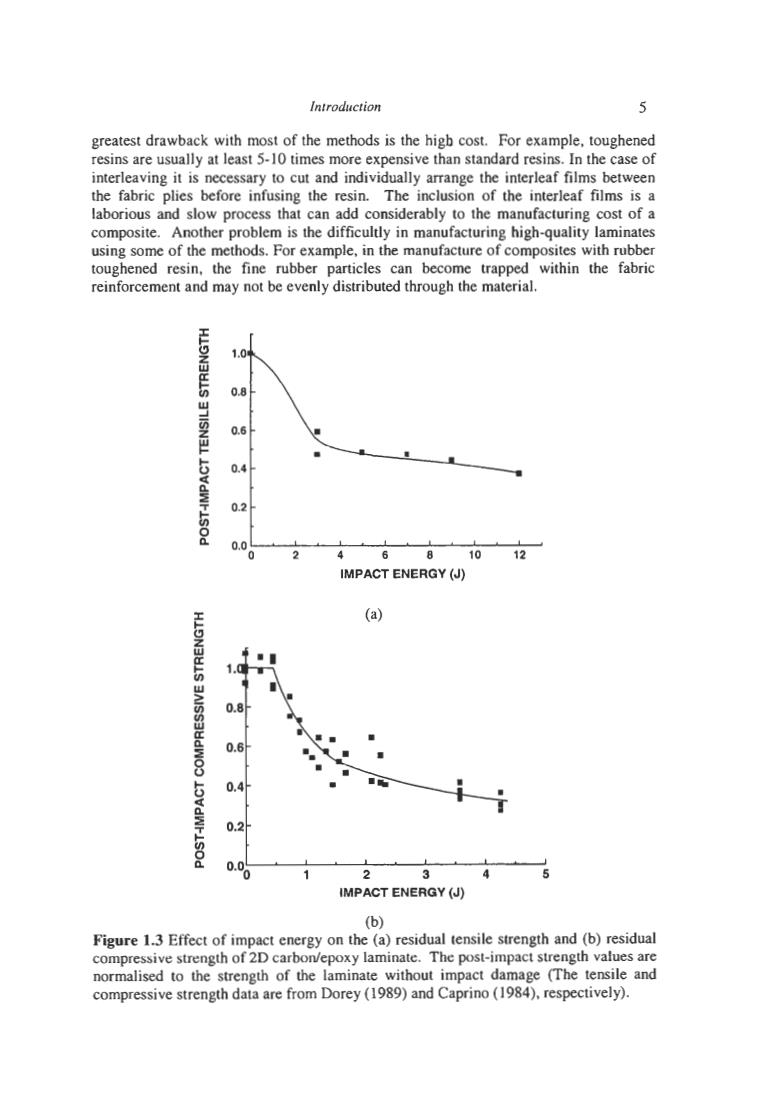

Introduction 5 greatest drawback with most of the methods is the higb cost.For example,toughened resins are usually at least 5-10 times more expensive than standard resins.In the case of interleaving it is necessary to cut and individually arrange the interleaf films between the fabric plies before infusing the resin.The inclusion of the interleaf films is a laborious and slow process that can add considerably to the manufacturing cost of a composite.Another problem is the difficultly in manufacturing high-quality laminates using some of the methods.For example,in the manufacture of composites with rubber toughened resin,the fine rubber particles can become trapped within the fabric reinforcement and may not be evenly distributed through the material. 0.8 0.6 0.4 0.2 0.0 6 810 12 IMPACT ENERGY(J) (a) 0.8 0.6 0.4 0.2 0.0 3 IMPACT ENERGY(J) (b) Figure 1.3 Effect of impact energy on the(a)residual tensile strength and (b)residual compressive strength of 2D carbon/epoxy laminate.The post-impact strength values are normalised to the strength of the laminate without impact damage (The tensile and compressive strength data are from Dorey (1989)and Caprino(1984).respectively)