正在加载图片...

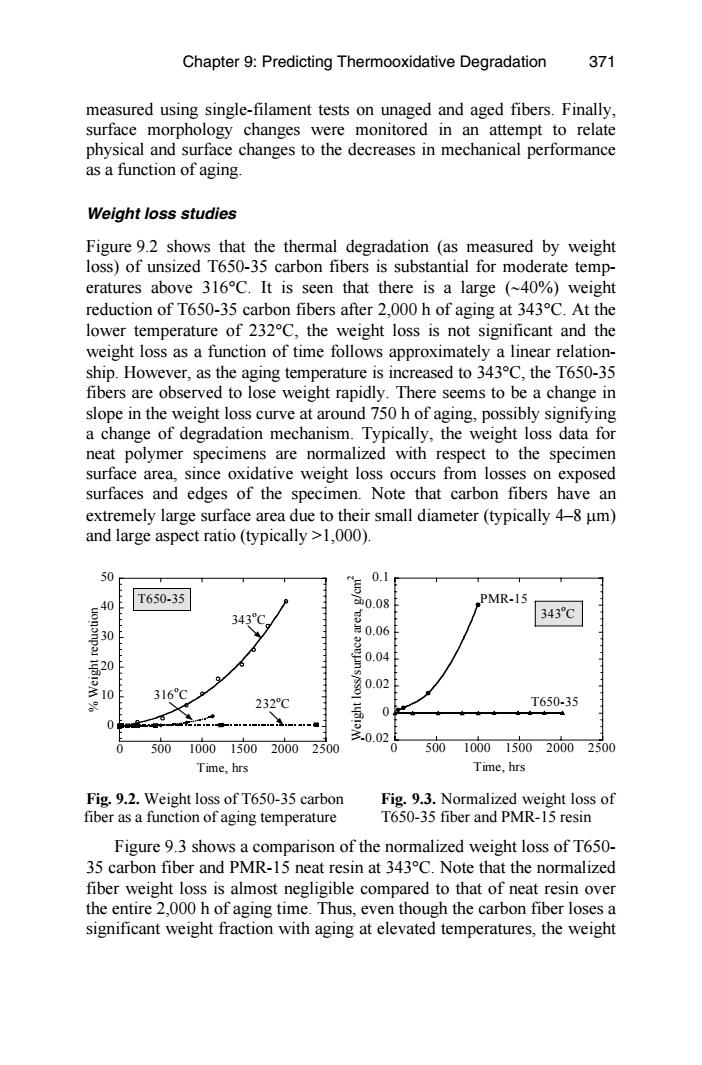

Chapter 9:Predicting Thermooxidative Degradation 371 measured using single-filament tests on unaged and aged fibers.Finally, surface morphology changes were monitored in an attempt to relate physical and surface changes to the decreases in mechanical performance as a function of aging Weight loss studies Figure 9.2 shows that the thermal degradation (as measured by weight loss)of unsized T650-35 carbon fibers is substantial for moderate temp- eratures above 316C.It is seen that there is a large (~40%)weight reduction of T650-35 carbon fibers after 2,000 h of aging at 343C.At the lower temperature of 232C,the weight loss is not significant and the weight loss as a function of time follows approximately a linear relation- ship.However,as the aging temperature is increased to 343C,the T650-35 fibers are observed to lose weight rapidly.There seems to be a change in slope in the weight loss curve at around 750 h of aging,possibly signifying a change of degradation mechanism.Typically,the weight loss data for neat polymer specimens are normalized with respect to the specimen surface area,since oxidative weight loss occurs from losses on exposed surfaces and edges of the specimen.Note that carbon fibers have an extremely large surface area due to their small diameter(typically 4-8 um) and large aspect ratio(typically >1,000). 50 0.1 PMR-15 40 T650-35 e0.08 341 006 343℃ 316℃ 232℃ T650-35 0 0 5001000150020002500 要o2月 05001000150020002500 Time,hrs Time,hrs Fig.9.2.Weight loss of T650-35 carbon Fig.9.3.Normalized weight loss of fiber as a function of aging temperature T650-35 fiber and PMR-15 resin Figure 9.3 shows a comparison of the normalized weight loss of T650- 35 carbon fiber and PMR-15 neat resin at 343C.Note that the normalized fiber weight loss is almost negligible compared to that of neat resin over the entire 2,000 h of aging time.Thus,even though the carbon fiber loses a significant weight fraction with aging at elevated temperatures,the weightmeasured using single-filament tests on unaged and aged fibers. Finally, surface morphology changes were monitored in an attempt to relate physical and surface changes to the decreases in mechanical performance as a function of aging. Weight loss studies Figure 9.2 shows that the thermal degradation (as measured by weight loss) of unsized T650-35 carbon fibers is substantial for moderate temperatures above 316°C. It is seen that there is a large (∼40%) weight reduction of T650-35 carbon fibers after 2,000 h of aging at 343°C. At the lower temperature of 232°C, the weight loss is not significant and the weight loss as a function of time follows approximately a linear relationship. However, as the aging temperature is increased to 343°C, the T650-35 fibers are observed to lose weight rapidly. There seems to be a change in slope in the weight loss curve at around 750 h of aging, possibly signifying a change of degradation mechanism. Typically, the weight loss data for neat polymer specimens are normalized with respect to the specimen surface area, since oxidative weight loss occurs from losses on exposed surfaces and edges of the specimen. Note that carbon fibers have an extremely large surface area due to their small diameter (typically 4–8 µm) and large aspect ratio (typically >1,000). Fig. 9.2. Weight loss of T650-35 carbon fiber as a function of aging temperature T650-35 fiber and PMR-15 resin Figure 9.3 shows a comparison of the normalized weight loss of T650- 35 carbon fiber and PMR-15 neat resin at 343°C. Note that the normalized fiber weight loss is almost negligible compared to that of neat resin over the entire 2,000 h of aging time. Thus, even though the carbon fiber loses a significant weight fraction with aging at elevated temperatures, the weight -0.02 0 0.02 0.04 0.06 0.08 0.1 0 500 1000 1500 2000 2500 Weight loss/surface area, g/cm2 Time, hrs PMR-15 T650-35 343o C 0 10 20 30 40 50 0 500 1000 1500 2000 2500 % Weight reduction Time, hrs T650-35 343o C 232o C 316o C Chapter 9: Predicting Thermooxidative Degradation Fig. 9.3. Normalized weight loss of 371