正在加载图片...

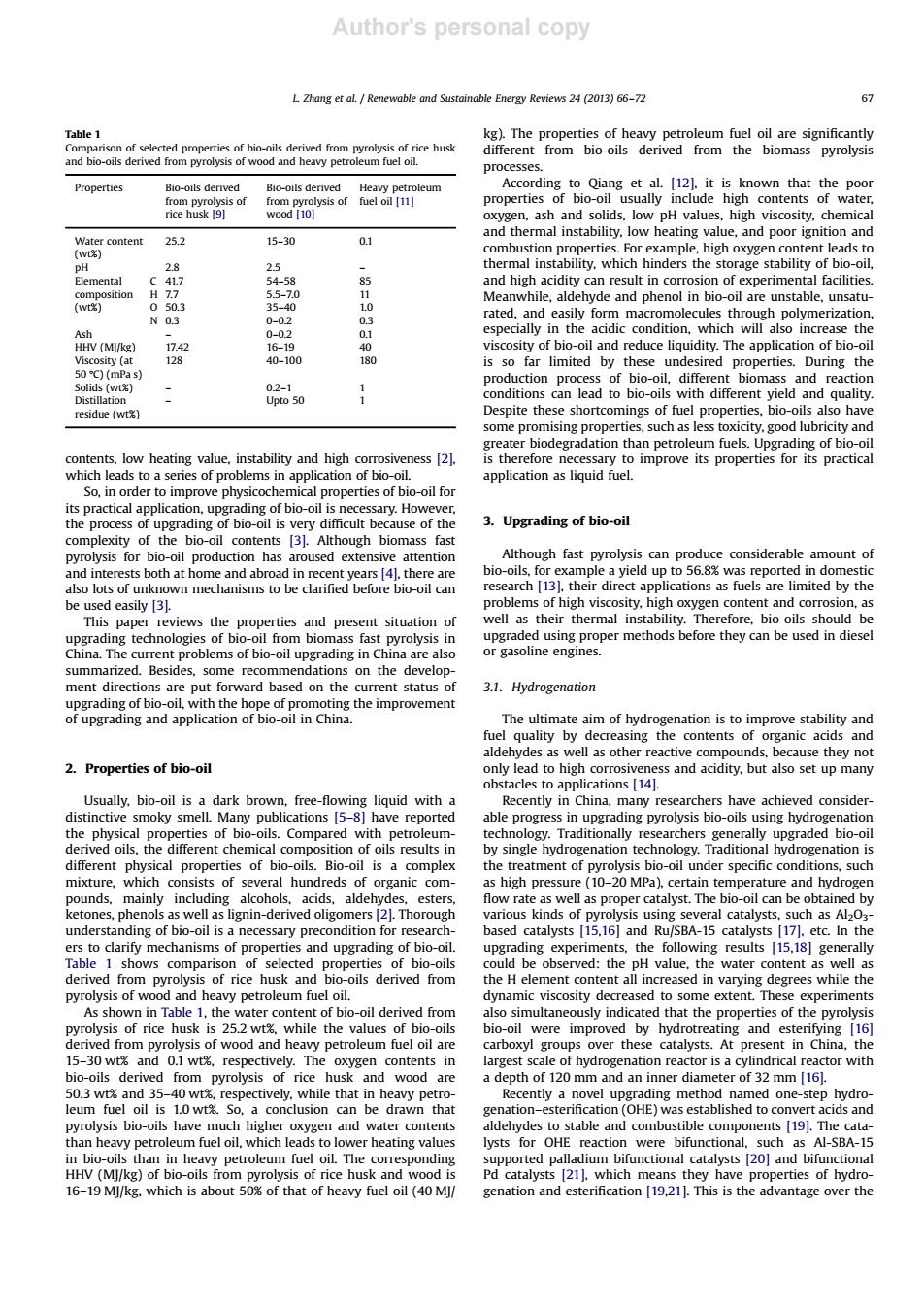

Author's personal copy L.Zhang et al.Renewable and Sustainable Energy Reviews 24(2013)66-72 父 Table 1 kg).The properties of heavy petroleum fuel oil are significantly Comparison of selected properties of bio-oils derived from pyrolysis of rice husk different from bio-oils derived from the biomass pyrolysis and bio-oils derived from pyrolysis of wood and heavy petroleum fuel oil. processes. Properties Bio-oils derived Bio-oils derived Heavy petroleum According to Qiang et al.[12].it is known that the poor from pyrol小ysis of from pyrolysis of fuel oil [11] properties of bio-oil usually include high contents of water rice husk [9] wood [10] oxygen,ash and solids,low pH values,high viscosity.chemical and thermal instability.low heating value,and poor ignition and Water content 25.2 15-30 0.1 (wt%) combustion properties.For example,high oxygen content leads to pH 2.8 2.5 thermal instability,which hinders the storage stability of bio-oil, Elemental C41.7 54-58 85 and high acidity can result in corrosion of experimental facilities composition H77 55-7.0 11 Meanwhile,aldehyde and phenol in bio-oil are unstable,unsatu- (wt%) 050.3 35-40 1.0 N0.3 0-02 03 rated,and easily form macromolecules through polymerization, Ash 0-02 0.1 especially in the acidic condition,which will also increase the HHV (MJ/kg) 17.42 16-19 40 viscosity of bio-oil and reduce liquidity.The application of bio-oil Viscosity (at 128 40-100 180 is so far limited by these undesired properties.During the 50*C)(mPa s) production process of bio-oil,different biomass and reaction Solids (wt) 02-1 1 Distillation Upto 50 conditions can lead to bio-oils with different yield and quality. residue (wt) Despite these shortcomings of fuel properties,bio-oils also have some promising properties,such as less toxicity,good lubricity and greater biodegradation than petroleum fuels.Upgrading of bio-oil contents,low heating value,instability and high corrosiveness [2] is therefore necessary to improve its properties for its practical which leads to a series of problems in application of bio-oil. application as liquid fuel. So,in order to improve physicochemical properties of bio-oil for its practical application,upgrading of bio-oil is necessary.However. the process of upgrading of bio-oil is very difficult because of the 3.Upgrading of bio-oil complexity of the bio-oil contents [3].Although biomass fast pyrolysis for bio-oil production has aroused extensive attention Although fast pyrolysis can produce considerable amount of and interests both at home and abroad in recent years [4].there are bio-oils,for example a yield up to 56.8%was reported in domestic also lots of unknown mechanisms to be clarified before bio-oil can research [13].their direct applications as fuels are limited by the be used easily [3]. problems of high viscosity,high oxygen content and corrosion,as This paper reviews the properties and present situation of well as their thermal instability.Therefore,bio-oils should be upgrading technologies of bio-oil from biomass fast pyrolysis in upgraded using proper methods before they can be used in diesel China.The current problems of bio-oil upgrading in China are also or gasoline engines summarized.Besides,some recommendations on the develop- ment directions are put forward based on the current status of 3.1.Hydrogenation upgrading of bio-oil,with the hope of promoting the improvement of upgrading and application of bio-oil in China. The ultimate aim of hydrogenation is to improve stability and fuel quality by decreasing the contents of organic acids and aldehydes as well as other reactive compounds,because they not 2.Properties of bio-oil only lead to high corrosiveness and acidity,but also set up many obstacles to applications [14. Usually,bio-oil is a dark brown,free-flowing liquid with a Recently in China,many researchers have achieved consider- distinctive smoky smell.Many publications [5-8]have reported able progress in upgrading pyrolysis bio-oils using hydrogenation the physical properties of bio-oils.Compared with petroleum- technology.Traditionally researchers generally upgraded bio-oil derived oils,the different chemical composition of oils results in by single hydrogenation technology.Traditional hydrogenation is different physical properties of bio-oils.Bio-oil is a complex the treatment of pyrolysis bio-oil under specific conditions,such mixture,which consists of several hundreds of organic com- as high pressure(10-20 MPa).certain temperature and hydrogen pounds,mainly including alcohols,acids,aldehydes,esters, flow rate as well as proper catalyst.The bio-oil can be obtained by ketones,phenols as well as lignin-derived oligomers [2].Thorough various kinds of pyrolysis using several catalysts,such as Al2O3- understanding of bio-oil is a necessary precondition for research- based catalysts [15.16]and Ru/SBA-15 catalysts [17].etc.In the ers to clarify mechanisms of properties and upgrading of bio-oil. upgrading experiments,the following results [15,18]generally Table 1 shows comparison of selected properties of bio-oils could be observed:the pH value,the water content as well as derived from pyrolysis of rice husk and bio-oils derived from the H element content all increased in varying degrees while the pyrolysis of wood and heavy petroleum fuel oil. dynamic viscosity decreased to some extent.These experiments As shown in Table 1,the water content of bio-oil derived from also simultaneously indicated that the properties of the pyrolysis pyrolysis of rice husk is 25.2 wt%,while the values of bio-oils bio-oil were improved by hydrotreating and esterifying [16] derived from pyrolysis of wood and heavy petroleum fuel oil are carboxyl groups over these catalysts.At present in China,the 15-30 wt%and 0.1 wt%,respectively.The oxygen contents in largest scale of hydrogenation reactor is a cylindrical reactor with bio-oils derived from pyrolysis of rice husk and wood are a depth of 120 mm and an inner diameter of 32 mm [16]. 50.3 wt%and 35-40 wt%,respectively.while that in heavy petro- Recently a novel upgrading method named one-step hydro- leum fuel oil is 1.0 wt%.So,a conclusion can be drawn that genation-esterification(OHE)was established to convert acids and pyrolysis bio-oils have much higher oxygen and water contents aldehydes to stable and combustible components [19].The cata- than heavy petroleum fuel oil,which leads to lower heating values lysts for OHE reaction were bifunctional,such as Al-SBA-15 in bio-oils than in heavy petroleum fuel oil.The corresponding supported palladium bifunctional catalysts [20]and bifunctiona HHV (MJ/kg)of bio-oils from pyrolysis of rice husk and wood is Pd catalysts [21].which means they have properties of hydro- 16-19 MJ/kg.which is about 50%of that of heavy fuel oil (40 MJ/ genation and esterification [19,21].This is the advantage over theAuthor's personal copy contents, low heating value, instability and high corrosiveness [2], which leads to a series of problems in application of bio-oil. So, in order to improve physicochemical properties of bio-oil for its practical application, upgrading of bio-oil is necessary. However, the process of upgrading of bio-oil is very difficult because of the complexity of the bio-oil contents [3]. Although biomass fast pyrolysis for bio-oil production has aroused extensive attention and interests both at home and abroad in recent years [4], there are also lots of unknown mechanisms to be clarified before bio-oil can be used easily [3]. This paper reviews the properties and present situation of upgrading technologies of bio-oil from biomass fast pyrolysis in China. The current problems of bio-oil upgrading in China are also summarized. Besides, some recommendations on the development directions are put forward based on the current status of upgrading of bio-oil, with the hope of promoting the improvement of upgrading and application of bio-oil in China. 2. Properties of bio-oil Usually, bio-oil is a dark brown, free-flowing liquid with a distinctive smoky smell. Many publications [5–8] have reported the physical properties of bio-oils. Compared with petroleumderived oils, the different chemical composition of oils results in different physical properties of bio-oils. Bio-oil is a complex mixture, which consists of several hundreds of organic compounds, mainly including alcohols, acids, aldehydes, esters, ketones, phenols as well as lignin-derived oligomers [2]. Thorough understanding of bio-oil is a necessary precondition for researchers to clarify mechanisms of properties and upgrading of bio-oil. Table 1 shows comparison of selected properties of bio-oils derived from pyrolysis of rice husk and bio-oils derived from pyrolysis of wood and heavy petroleum fuel oil. As shown in Table 1, the water content of bio-oil derived from pyrolysis of rice husk is 25.2 wt%, while the values of bio-oils derived from pyrolysis of wood and heavy petroleum fuel oil are 15–30 wt% and 0.1 wt%, respectively. The oxygen contents in bio-oils derived from pyrolysis of rice husk and wood are 50.3 wt% and 35–40 wt%, respectively, while that in heavy petroleum fuel oil is 1.0 wt%. So, a conclusion can be drawn that pyrolysis bio-oils have much higher oxygen and water contents than heavy petroleum fuel oil, which leads to lower heating values in bio-oils than in heavy petroleum fuel oil. The corresponding HHV (MJ/kg) of bio-oils from pyrolysis of rice husk and wood is 16–19 MJ/kg, which is about 50% of that of heavy fuel oil (40 MJ/ kg). The properties of heavy petroleum fuel oil are significantly different from bio-oils derived from the biomass pyrolysis processes. According to Qiang et al. [12], it is known that the poor properties of bio-oil usually include high contents of water, oxygen, ash and solids, low pH values, high viscosity, chemical and thermal instability, low heating value, and poor ignition and combustion properties. For example, high oxygen content leads to thermal instability, which hinders the storage stability of bio-oil, and high acidity can result in corrosion of experimental facilities. Meanwhile, aldehyde and phenol in bio-oil are unstable, unsaturated, and easily form macromolecules through polymerization, especially in the acidic condition, which will also increase the viscosity of bio-oil and reduce liquidity. The application of bio-oil is so far limited by these undesired properties. During the production process of bio-oil, different biomass and reaction conditions can lead to bio-oils with different yield and quality. Despite these shortcomings of fuel properties, bio-oils also have some promising properties, such as less toxicity, good lubricity and greater biodegradation than petroleum fuels. Upgrading of bio-oil is therefore necessary to improve its properties for its practical application as liquid fuel. 3. Upgrading of bio-oil Although fast pyrolysis can produce considerable amount of bio-oils, for example a yield up to 56.8% was reported in domestic research [13], their direct applications as fuels are limited by the problems of high viscosity, high oxygen content and corrosion, as well as their thermal instability. Therefore, bio-oils should be upgraded using proper methods before they can be used in diesel or gasoline engines. 3.1. Hydrogenation The ultimate aim of hydrogenation is to improve stability and fuel quality by decreasing the contents of organic acids and aldehydes as well as other reactive compounds, because they not only lead to high corrosiveness and acidity, but also set up many obstacles to applications [14]. Recently in China, many researchers have achieved considerable progress in upgrading pyrolysis bio-oils using hydrogenation technology. Traditionally researchers generally upgraded bio-oil by single hydrogenation technology. Traditional hydrogenation is the treatment of pyrolysis bio-oil under specific conditions, such as high pressure (10–20 MPa), certain temperature and hydrogen flow rate as well as proper catalyst. The bio-oil can be obtained by various kinds of pyrolysis using several catalysts, such as Al2O3- based catalysts [15,16] and Ru/SBA-15 catalysts [17], etc. In the upgrading experiments, the following results [15,18] generally could be observed: the pH value, the water content as well as the H element content all increased in varying degrees while the dynamic viscosity decreased to some extent. These experiments also simultaneously indicated that the properties of the pyrolysis bio-oil were improved by hydrotreating and esterifying [16] carboxyl groups over these catalysts. At present in China, the largest scale of hydrogenation reactor is a cylindrical reactor with a depth of 120 mm and an inner diameter of 32 mm [16]. Recently a novel upgrading method named one-step hydrogenation–esterification (OHE) was established to convert acids and aldehydes to stable and combustible components [19]. The catalysts for OHE reaction were bifunctional, such as Al-SBA-15 supported palladium bifunctional catalysts [20] and bifunctional Pd catalysts [21], which means they have properties of hydrogenation and esterification [19,21]. This is the advantage over the Table 1 Comparison of selected properties of bio-oils derived from pyrolysis of rice husk and bio-oils derived from pyrolysis of wood and heavy petroleum fuel oil. Properties Bio-oils derived from pyrolysis of rice husk [9] Bio-oils derived from pyrolysis of wood [10] Heavy petroleum fuel oil [11] Water content (wt%) 25.2 15–30 0.1 pH 2.8 2.5 – Elemental composition (wt%) C 41.7 54–58 85 H 7.7 5.5–7.0 11 O 50.3 35–40 1.0 N 0.3 0–0.2 0.3 Ash – 0–0.2 0.1 HHV (MJ/kg) 17.42 16–19 40 Viscosity (at 50 1C) (mPa s) 128 40–100 180 Solids (wt%) – 0.2–1 1 Distillation residue (wt%) – Upto 50 1 L. Zhang et al. / Renewable and Sustainable Energy Reviews 24 (2013) 66–72 67