正在加载图片...

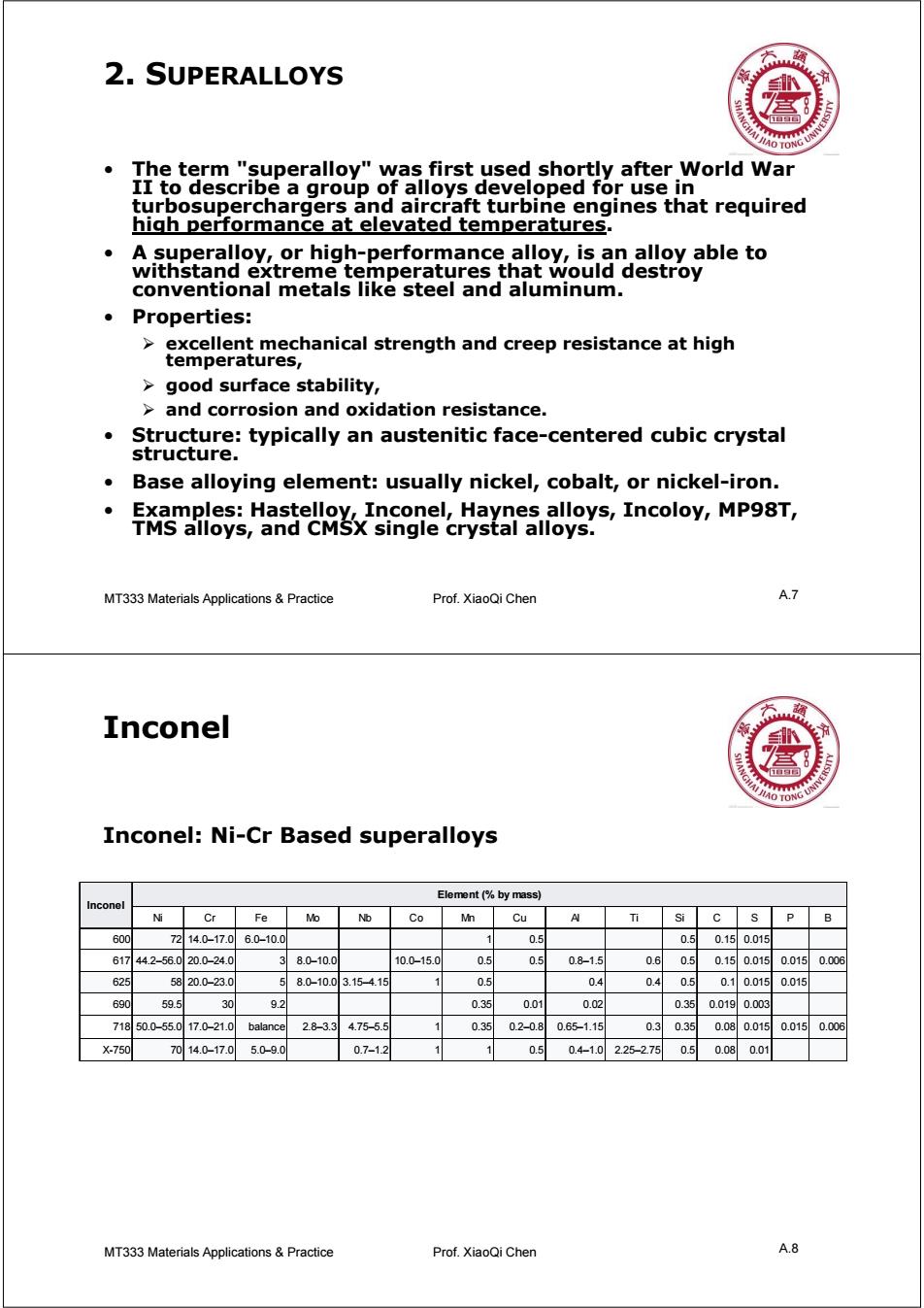

2.SUPERALLOYS The term "superalloy"was first used shortly after World War II to describe a group of alloys developed for use in turbosuperchargers and aircraft turbine engines that required high performance at elevated temperatures. A superalloy,or high-performance alloy,is an alloy able to withstand extreme temperatures that would destroy conventional metals like steel and aluminum. Properties: excellent mechanical strength and creep resistance at high temperatures, >good surface stability, and corrosion and oxidation resistance. Structure:typically an austenitic face-centered cubic crystal structure. Base alloying element:usually nickel,cobalt,or nickel-iron. Examples:Hastelloy,Inconel,Haynes alloys,Incoloy,MP98T, TMS alloys,and CMSX single crystal alloys. MT333 Materials Applications Practice Prof.XiaoQi Chen A.7 Inconel O TONG U Inconel:Ni-Cr Based superalloys Element (by mass) Inconel g Cr Nb Co Mn Cu Si PB 600 7214.0-17.06.0-10.0 0.5 0.5 0.150.015 617 44.2-56.0 20.0-24.0 8.0-10.0 10.0-15.0 0.5 0.5 0.8-1.5 0.6 0.5 0.15 0.015 0.0150.006 625 5820.0-23.0 8.0-10.03.15-4.15 0.5 0.4 0.4 0.5 0.1 0.015 0.015 690 59.5 % 9.2 0.35 0.01 0.02 0.35 0.019 0.003 71850.0-55.017.0-21.0 balance 2.8-3.3 4.75-5.5 0.35 02-0.8 0.65-1.15 0.35 0.08 0.015 0.0150.006 X-750 70 14.0-17.0 5.0-9.0 0.7-12 1 1 0.5 0.4-1.0 2.25-2.75 0.5 0.08 0.01 MT333 Materials Applications Practice Prof.XiaoQi Chen A.8MT333 Materials Applications A.7 & Practice Prof. XiaoQi Chen 2. SUPERALLOYS • The term "superalloy" was first used shortly after World War II to describe a group of alloys developed for use in turbosuperchargers and aircraft turbine engines that required high performance at elevated temperatures. • A superalloy, or high-performance alloy, is an alloy able to withstand extreme temperatures that would destroy conventional metals like steel and aluminum. • Properties: excellent mechanical strength and creep resistance at high temperatures, good surface stability, and corrosion and oxidation resistance. • Structure: typically an austenitic face-centered cubic crystal structure. • Base alloying element: usually nickel, cobalt, or nickel-iron. • Examples: Hastelloy, Inconel, Haynes alloys, Incoloy, MP98T, TMS alloys, and CMSX single crystal alloys. MT333 Materials Applications A.8 & Practice Prof. XiaoQi Chen Inconel Ni Cr Fe Mo Nb Co Mn Cu Al Ti Si C S P B 600 72 14.0–17.0 6.0–10.0 1 0.5 0.5 0.15 0.015 617 44.2–56.0 20.0–24.0 3 8.0–10.0 10.0–15.0 0.5 0.5 0.8–1.5 0.6 0.5 0.15 0.015 0.015 0.006 625 58 20.0–23.0 5 8.0–10.0 3.15–4.15 1 0.5 0.4 0.4 0.5 0.1 0.015 0.015 690 59.5 30 9.2 0.35 0.01 0.02 0.35 0.019 0.003 718 50.0–55.0 17.0–21.0 balance 2.8–3.3 4.75–5.5 1 0.35 0.2–0.8 0.65–1.15 0.3 0.35 0.08 0.015 0.015 0.006 X-750 70 14.0–17.0 5.0–9.0 0.7–1.2 1 1 0.5 0.4–1.0 2.25–2.75 0.5 0.08 0.01 Inconel Element (% by mass) Inconel: Ni-Cr Based superalloys