正在加载图片...

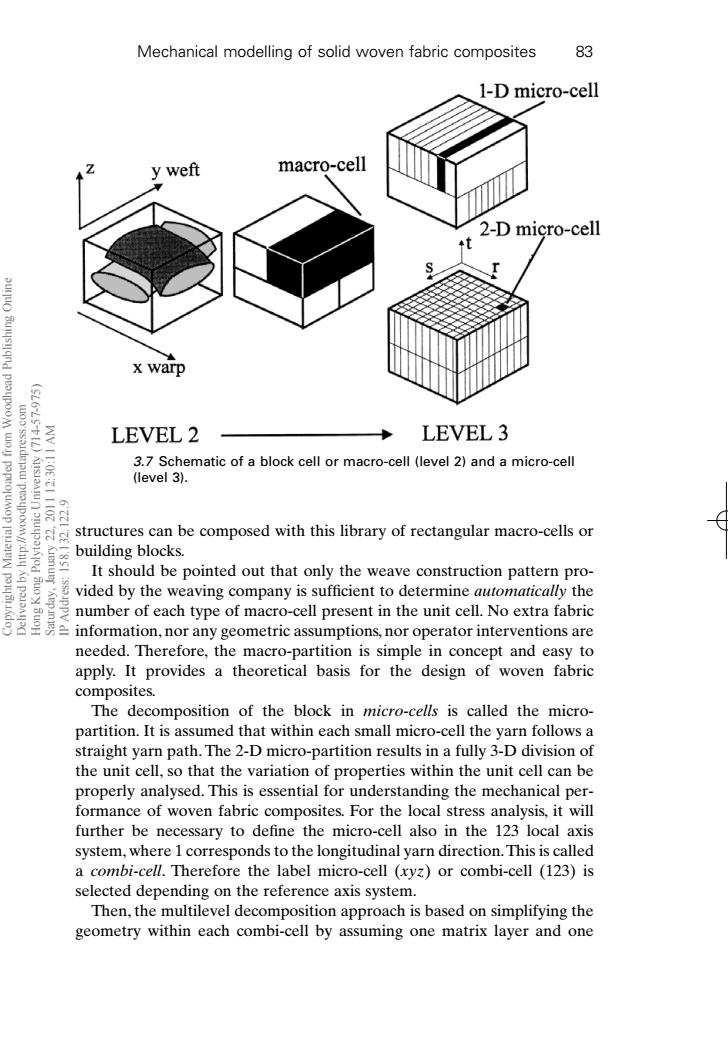

Mechanical modelling of solid woven fabric composites 83 1-D micro-cell y weft macro-cell t-migro-cell x warp 196t1 wo'ssaudmau'peaupoo/ WV IL:OE LEVEL 2 LEVEL 3 3.7 Schematic of a block cell or macro-cell (level 2)and a micro-cell (level 3). 日 structures can be composed with this library of rectangular macro-cells or I'85I building blocks. It should be pointed out that only the weave construction pattern pro- % vided by the weaving company is sufficient to determine automatically the number of each type of macro-cell present in the unit cell.No extra fabric information,nor any geometric assumptions,nor operator interventions are needed.Therefore,the macro-partition is simple in concept and easy to apply.It provides a theoretical basis for the design of woven fabric composites. The decomposition of the block in micro-cells is called the micro- partition.It is assumed that within each small micro-cell the yarn follows a straight yarn path.The 2-D micro-partition results in a fully 3-D division of the unit cell,so that the variation of properties within the unit cell can be properly analysed.This is essential for understanding the mechanical per- formance of woven fabric composites.For the local stress analysis,it will further be necessary to define the micro-cell also in the 123 local axis system,where 1 corresponds to the longitudinal yarn direction.This is called a combi-cell.Therefore the label micro-cell (xyz)or combi-cell (123)is selected depending on the reference axis system. Then,the multilevel decomposition approach is based on simplifying the geometry within each combi-cell by assuming one matrix layer and onestructures can be composed with this library of rectangular macro-cells or building blocks. It should be pointed out that only the weave construction pattern provided by the weaving company is sufficient to determine automatically the number of each type of macro-cell present in the unit cell. No extra fabric information, nor any geometric assumptions, nor operator interventions are needed. Therefore, the macro-partition is simple in concept and easy to apply. It provides a theoretical basis for the design of woven fabric composites. The decomposition of the block in micro-cells is called the micropartition. It is assumed that within each small micro-cell the yarn follows a straight yarn path. The 2-D micro-partition results in a fully 3-D division of the unit cell, so that the variation of properties within the unit cell can be properly analysed. This is essential for understanding the mechanical performance of woven fabric composites. For the local stress analysis, it will further be necessary to define the micro-cell also in the 123 local axis system, where 1 corresponds to the longitudinal yarn direction.This is called a combi-cell. Therefore the label micro-cell (xyz) or combi-cell (123) is selected depending on the reference axis system. Then, the multilevel decomposition approach is based on simplifying the geometry within each combi-cell by assuming one matrix layer and one Mechanical modelling of solid woven fabric composites 83 3.7 Schematic of a block cell or macro-cell (level 2) and a micro-cell (level 3). RIC3 7/10/99 7:37 PM Page 83 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:30:11 AM IP Address: 158.132.122.9